Dope-dyed polyester knitted looped fabric

A solution dyeing and polyester technology, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of wearing comfort, warmth, deodorization, poor moisture absorption, etc., and achieve simple processing technology and sun exposure Great effect on color fastness and high temperature washing color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

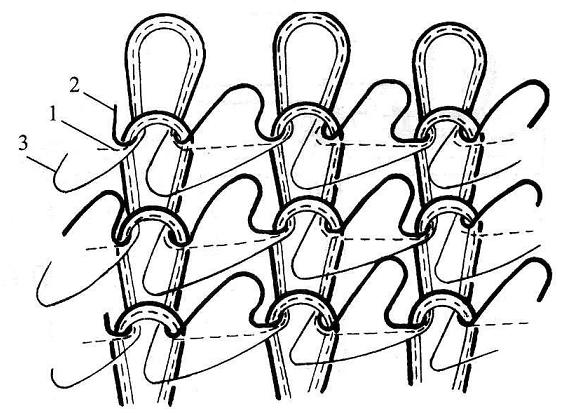

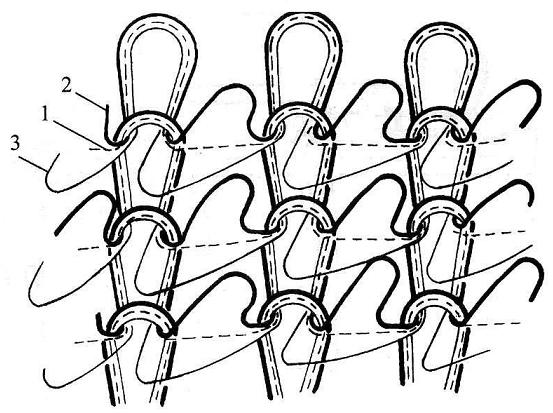

[0017] Such as figure 1 As shown, the dope dyed polyester needle terry fabric of the present invention is woven from three yarns by a double-sided circular terry knitting machine: the yarn 1 composed of polyester coconut carbon yarn is woven into a uniform grid-shaped basic structure The yarn 2 composed of dope-dyed polyester fiber and dope-dyed polyester composite stainless steel fiber interweaves with the basic weave to form a protruding front pile on one side of the basic weave; the dope-dyed polyester composite stainless steel fiber and polyester coconut carbon yarn are also used together The constituent yarns 3, interwoven with the basic weave, form reverse piles protruding on the other side of the basic weave.

[0018] Among them, the color fastness to sunlight of the dope-dyed polyester fiber is higher than grade 6, and the color fastness to washing at 60°C is higher than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com