Hydraulic control system with double-feedback active proportional servo cartridge valve for CNC (Computer Numerical Control) bending machine

A technology of hydraulic control system and proportional servo valve, which is applied in the direction of servo motor, servo motor assembly, fluid pressure actuator, etc., can solve the problems of low precision, large space occupation, and unstable movement of the bending machine, and achieve operation control Accurate and simple, reduce equipment cost, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

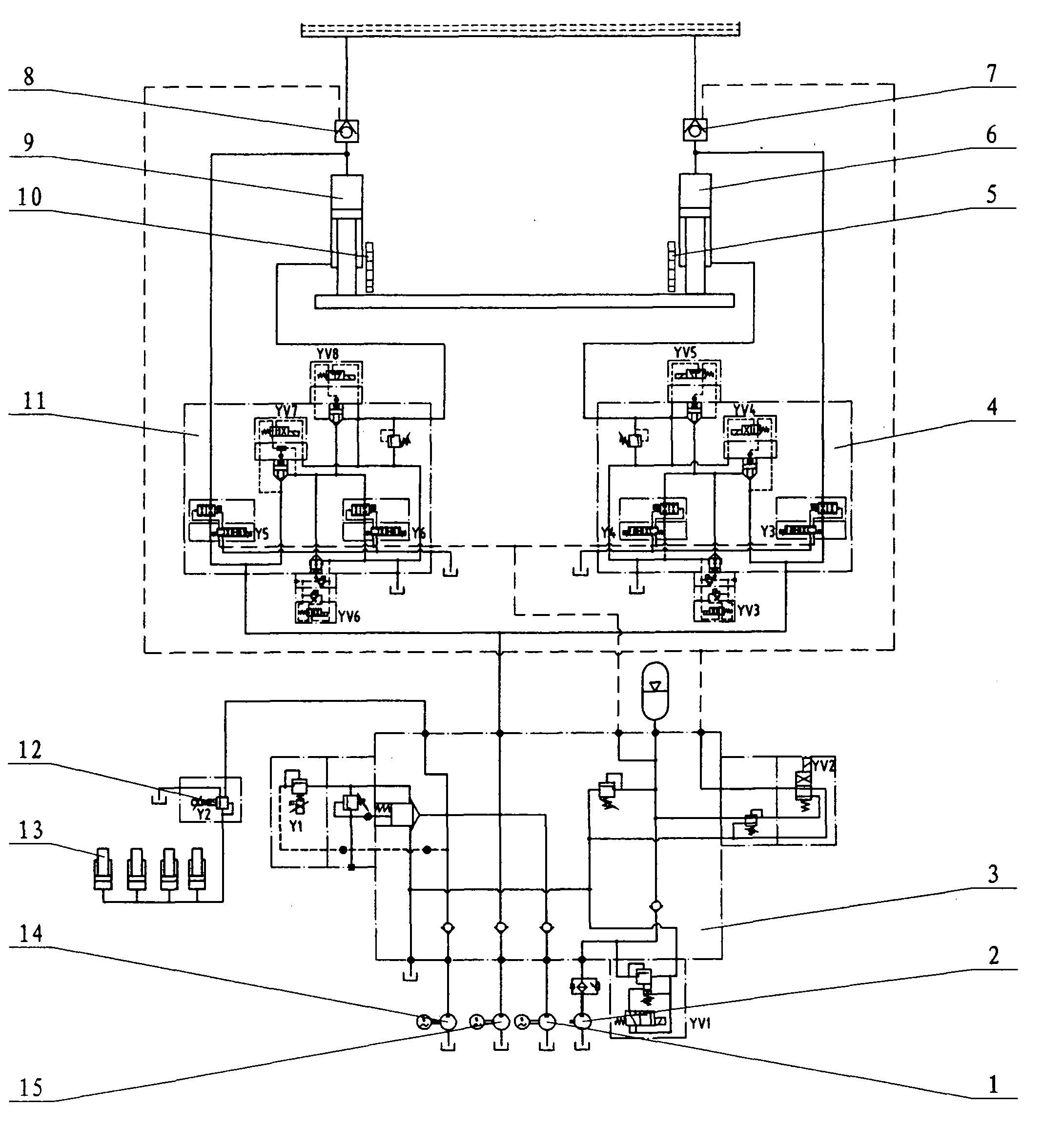

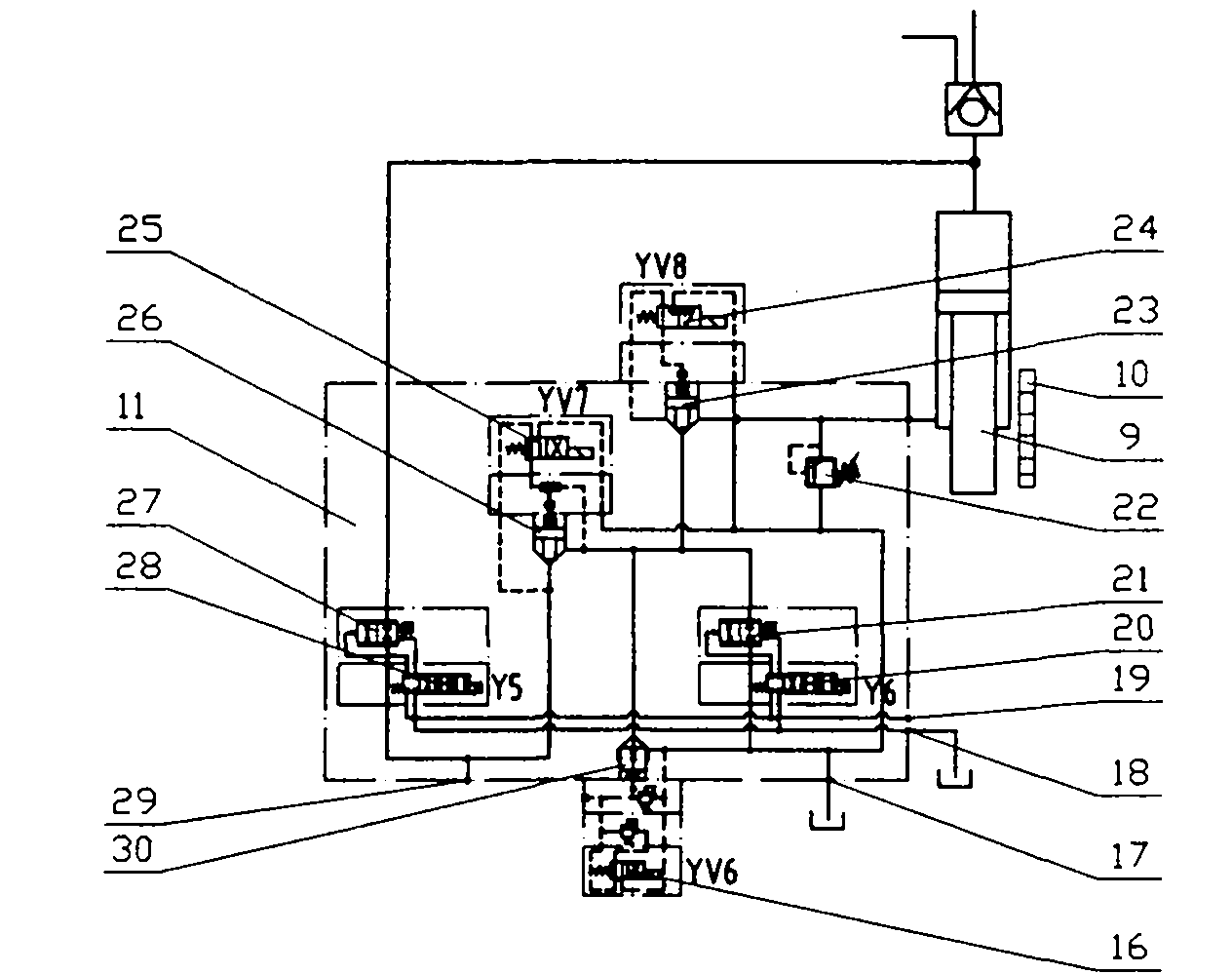

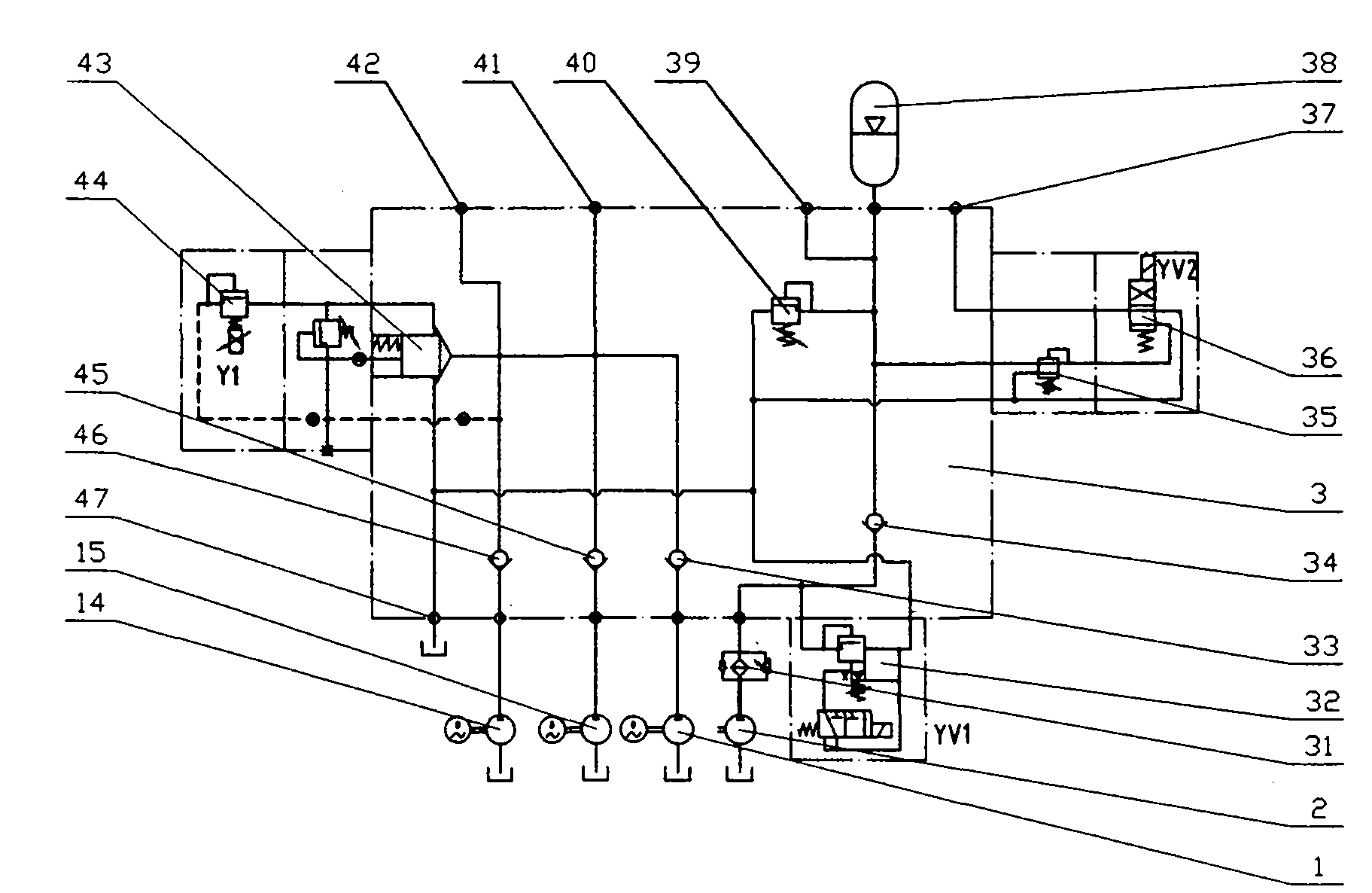

[0011] refer to figure 1 , 2 3. The hydraulic control system of the double feedback active proportional servo cartridge valve CNC bending machine of the present invention is composed of two main cylinder control valve groups, one oil inlet control valve group and one workbench compensation cylinder 13, two The main cylinder control valve group is set separately, and each valve group is equipped with two dual active servo cartridge valve units, a safety control unit and a pressure regulating unit, which respectively drive the corresponding master cylinder to ensure the synchronization position accuracy of each master cylinder; The oil control valve group controls the oil in and out and the proportional adjustment of the system pressure, and provides the pilot control oil of the dual active servo cartridge valve; the workbench compensation cylinder 13 is used for the workbench adjustment before bending; it is composed of pump, two-position four-way Solenoid directional valve, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com