Differential capacitor type micro-vibration sensor

A vibration sensor and differential-capacity micro technology, which is applied in the field of inertial measurement, can solve the problems of noise level and impact resistance of MEMS micro-machine capacitive accelerometers, difficulty in application, etc., and achieve good frequency response characteristics, convenient leads, relative area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementations based on the technical solution of the present invention, but the scope of protection of the present invention is not limited to the following embodiments.

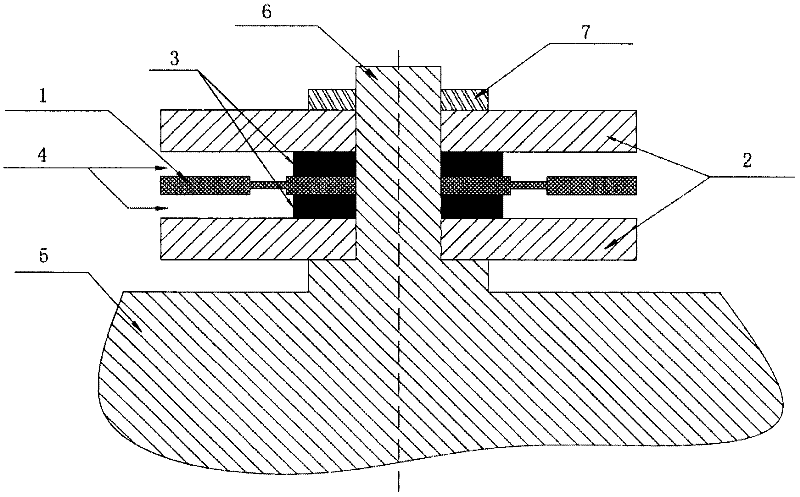

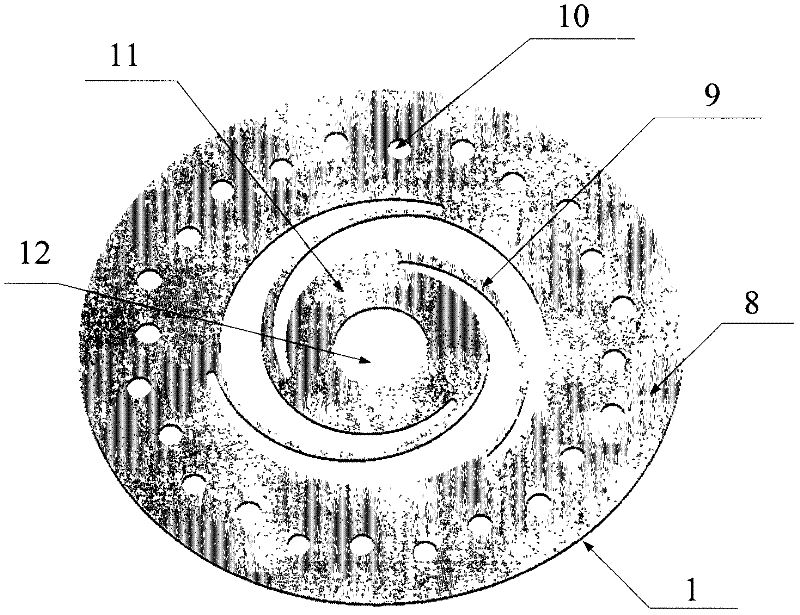

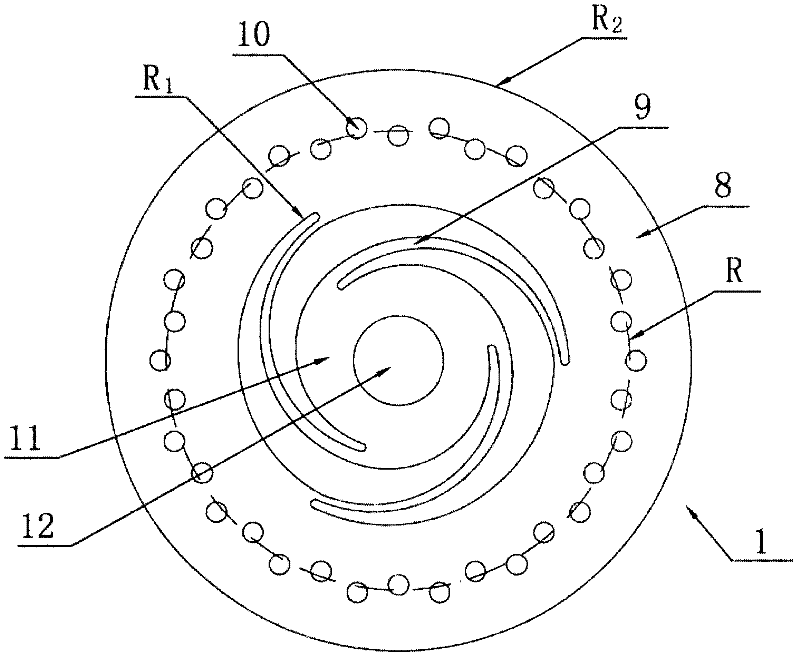

[0026] Such as figure 1 Shown is the schematic diagram of the structure of the differential-capacity micro-vibration sensor of the present invention. It can be seen from the figure that the sensor includes a capacitive moving plate 1, two capacitive fixed plates 2, two metal gaskets 3, a base 5, a mounting column 6, and an assembly Nut 7. The capacitive dynamic pole plate 1 is located between two capacitive fixed pole plates 2, and the two conductive pads 3 are respectively located between the capacitive dynamic pole plate 1 and the capacitive fixed pole plate 2, and the movable electrode on the capacitive dynamic pole plate 1 ( That is, a capacitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com