High-accuracy electromagnetic force controlled linear motor and control system thereof

A technology for controlling straight lines and control systems, applied in control systems, AC motor control, propulsion systems, etc., can solve problems such as easy oscillation and overshoot, weak anti-disturbance ability, etc., and achieve low oscillation and overshoot, anti-disturbance capabilities Strong, improve the effect of current control frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

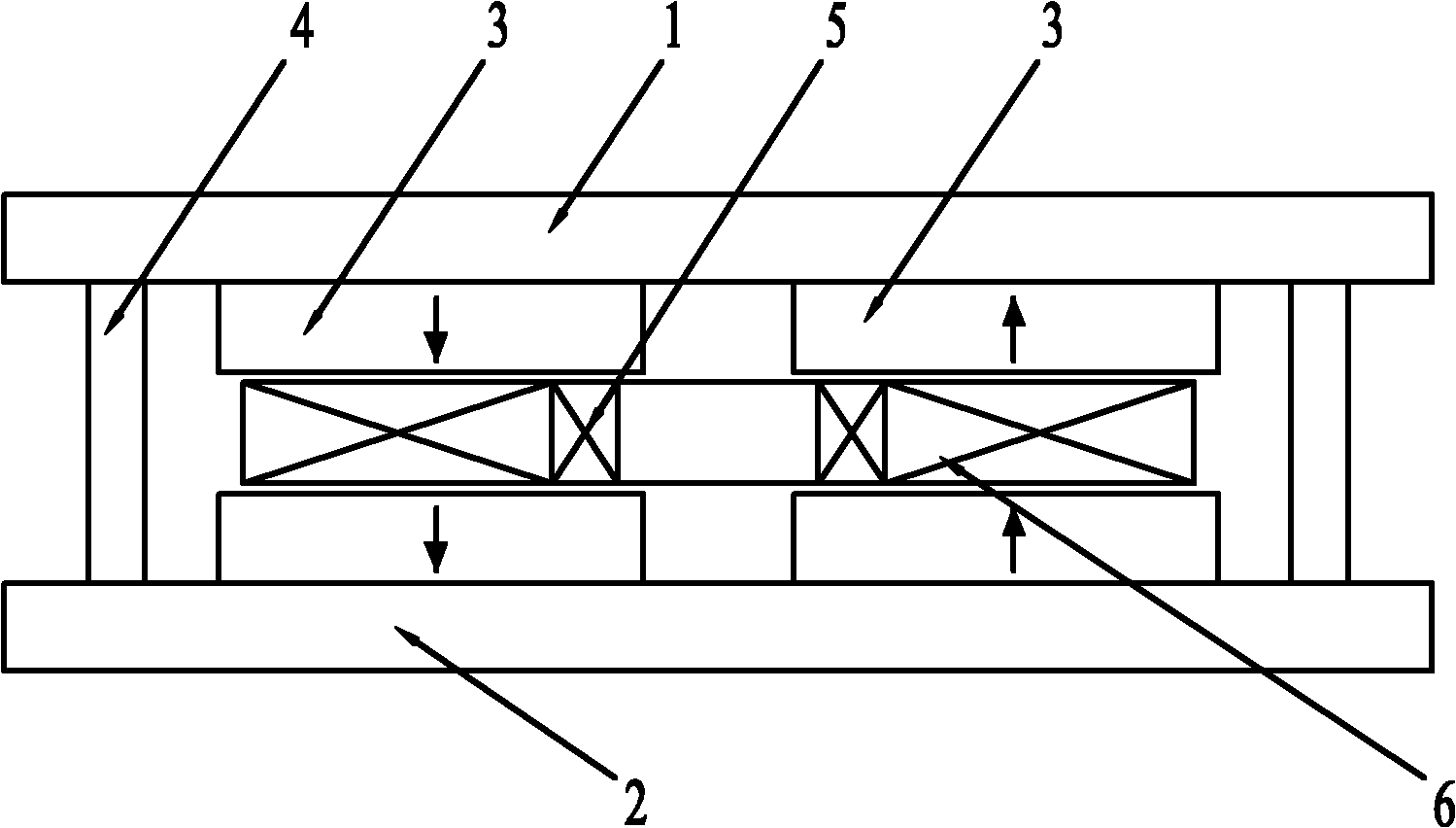

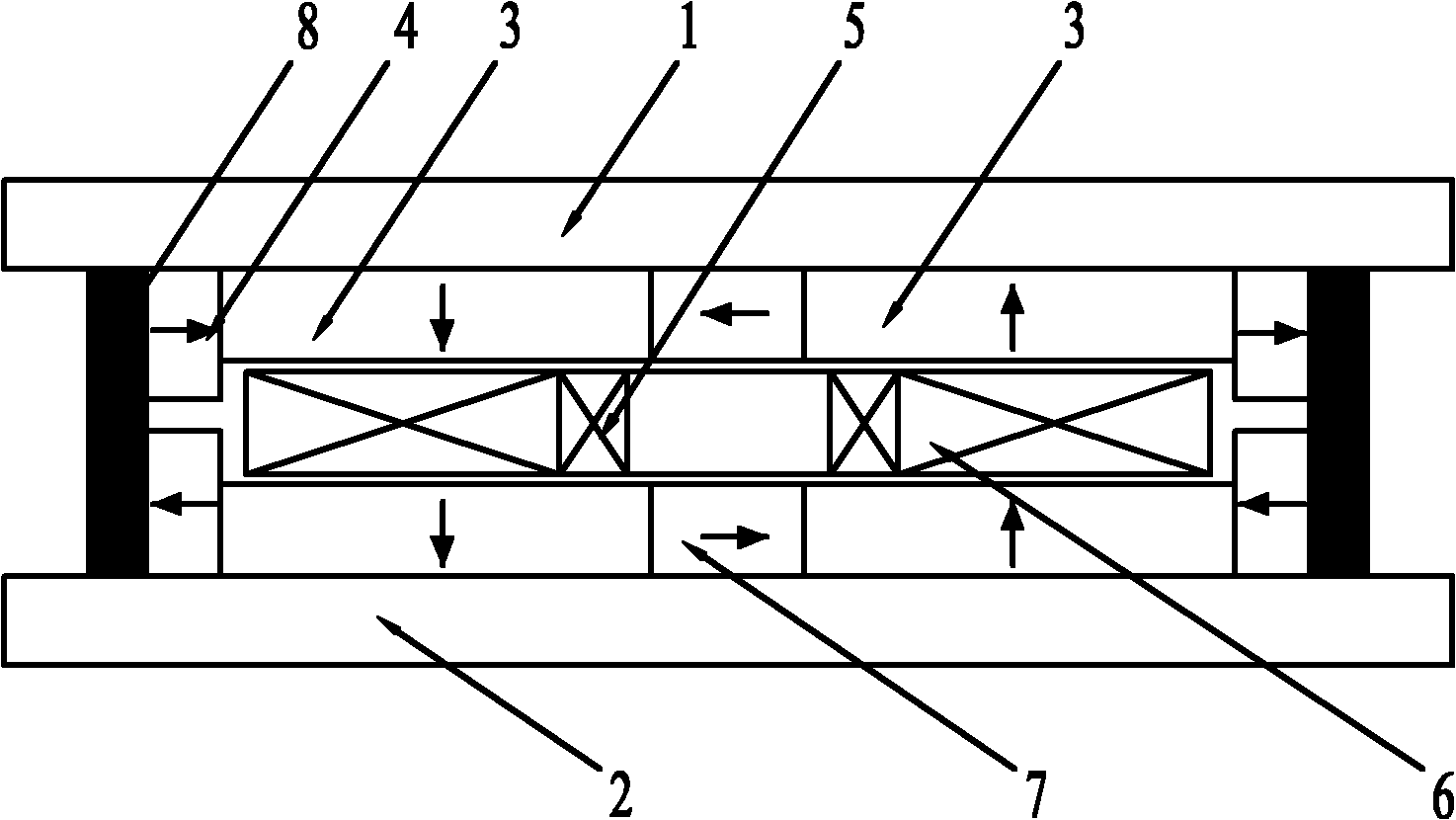

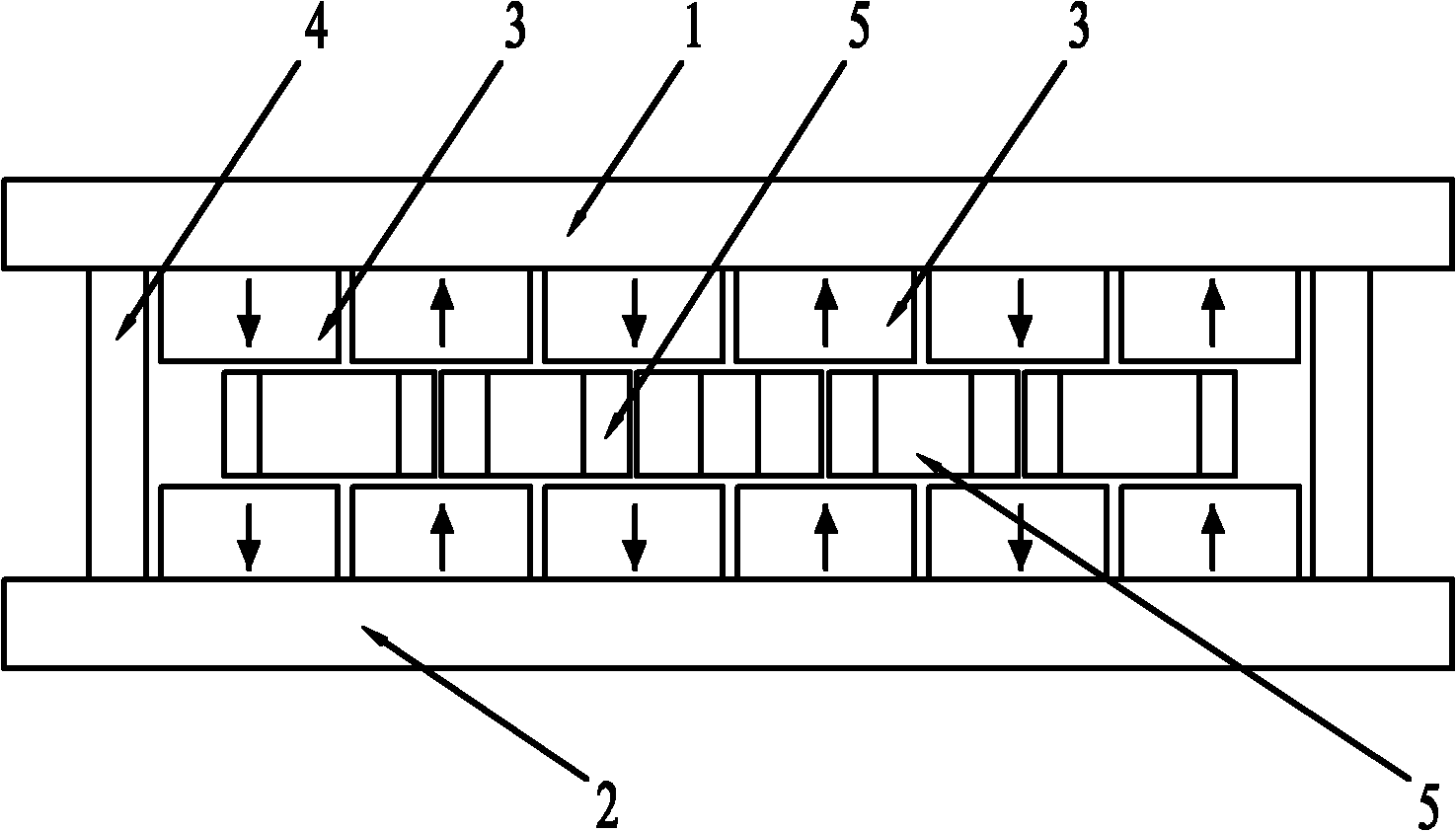

[0017] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the high-precision electromagnetic force control linear motor in this embodiment includes a primary and a secondary; an air gap is left between the primary and the secondary;

[0018] The secondary is composed of a plurality of permanent magnet units with the same structure, an upper magnetic yoke 1 and a lower magnetic yoke 2;

[0019] Each permanent magnet unit is composed of four main permanent magnets 3 and two elongated auxiliary permanent magnets 4;

[0020] The two main permanent magnets 2 are planar permanent magnets magnetized in parallel;

[0021] The four main permanent magnets 3 are equally divided into an upper main permanent magnet group and a lower main permanent magnet group;

[0022] The upper main permanent magnet group is fixedly arranged on the lower surface of the upper magnetic yoke 1; the lower main permanent magnet group is fixedly arranged on the upper surface of...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination Figure 4 This embodiment is described. This embodiment is a control system that adopts the high-precision electromagnetic force control linear motor described in Embodiment 1. It is composed of a high-precision electromagnetic force control linear motor and a plurality of identical drive control units;

[0034] The high-precision electromagnetic force controls the primary armature winding of each phase of the linear motor to draw three taps; each of the drive control units is respectively installed on the primary phase of the armature winding of the linear motor; each of the A drive control unit is made up of four drive controllers 9;

[0035] The two control output terminals of the first drive controller are respectively connected to the head end and the tail end of a phase armature winding; the two control output terminals of the second drive controller are respectively connected to the first tap of a phase armature windi...

specific Embodiment approach 3

[0036] Specific implementation mode three: combination Figure 5 This embodiment is described. This embodiment is a control system that adopts the high-precision electromagnetic force control linear motor described in Embodiment 1. It is composed of a high-precision electromagnetic force control linear motor and a plurality of identical drive control units;

[0037] The high-precision electromagnetic force controls the primary armature winding of each phase of the linear motor to draw three taps; each of the drive control units is respectively installed on the primary phase of the armature winding of the linear motor; each of the A drive control unit is made up of drive controller 9 and four switch 10;

[0038] A control output terminal of the drive controller is respectively connected with the head end of a phase armature winding, the first tap of a phase armature winding, the second tap of a phase armature winding and a phase electric current through four switch 10. The thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com