A method of improving swelling soil roadbed filling material by using waste carbide slag

A technology of carbide slag and soil roadbed, applied in the fields of geotechnical engineering, expansive soil treatment, road engineering, water conservancy engineering, can solve the problems of aggravating the global warming trend, reducing the project cost, unfavorable emission reduction policies, etc., to achieve a good economic Benefit, emission reduction, good social benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

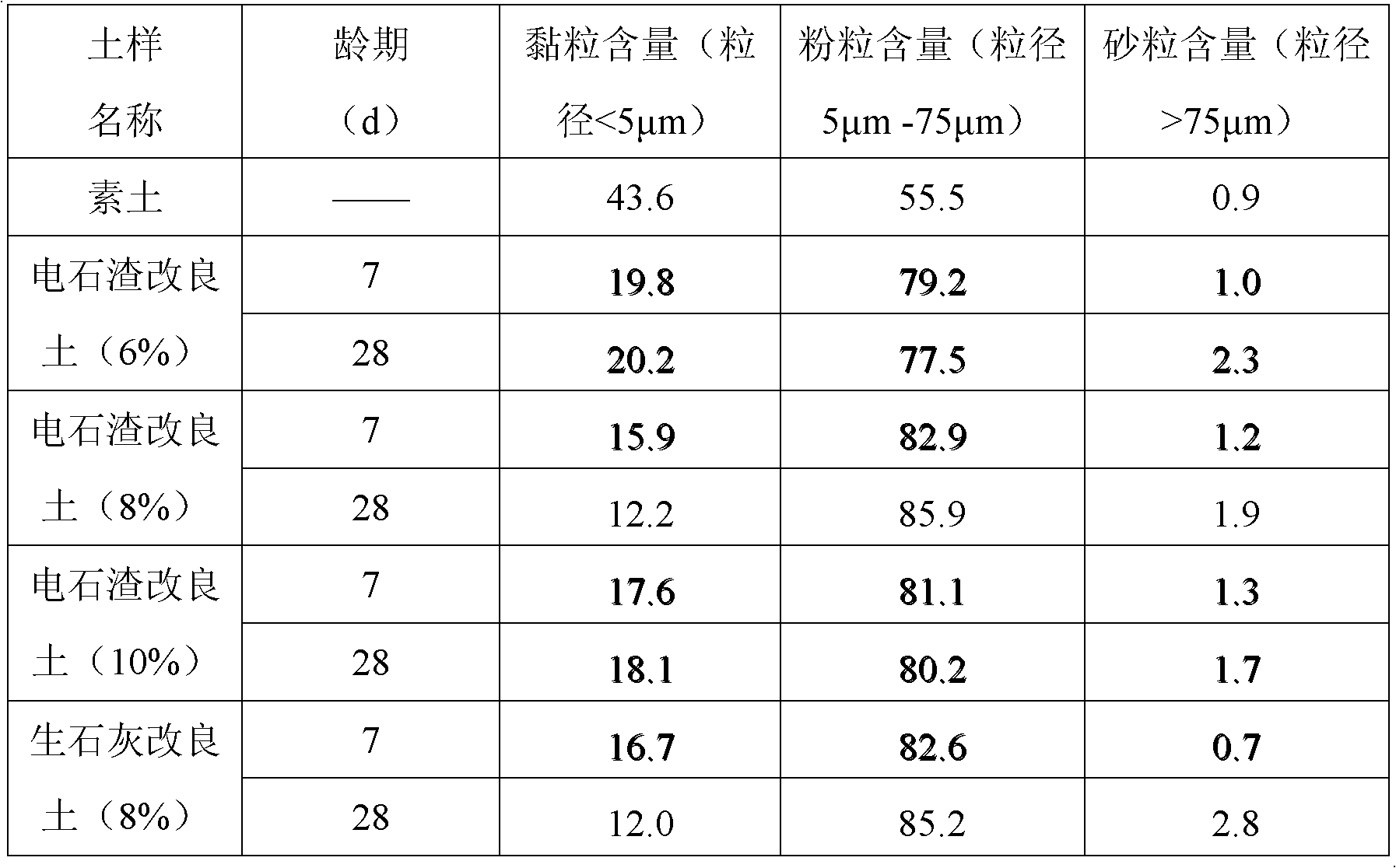

[0016] Below in conjunction with laboratory test result the present invention is described in more detail:

[0017] The effect of calcium carbide slag improving expansive soil is planned to be evaluated through the combination of indoor test and theoretical analysis, mainly from the physical and mechanical properties of calcium carbide slag improving expansive soil.

[0018] 1) Basic properties of expansive soil: the test soil is taken from a certain place in Anhui, with a free expansion rate of 76%, which belongs to strong expansive soil, and its basic index is liquid limit w L =142.4%, plastic limit w p =40.8%, the natural water content of the soil w=30.5%, the content of fine particles (particle sizedmax =1.21g / cm 3 , the optimal water content w op =25.2%, the expansion under the load of 50kPa is 13.35%.

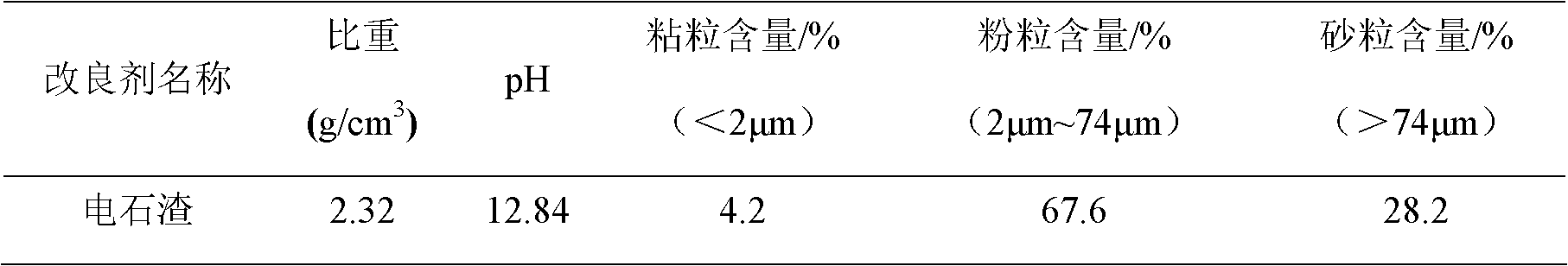

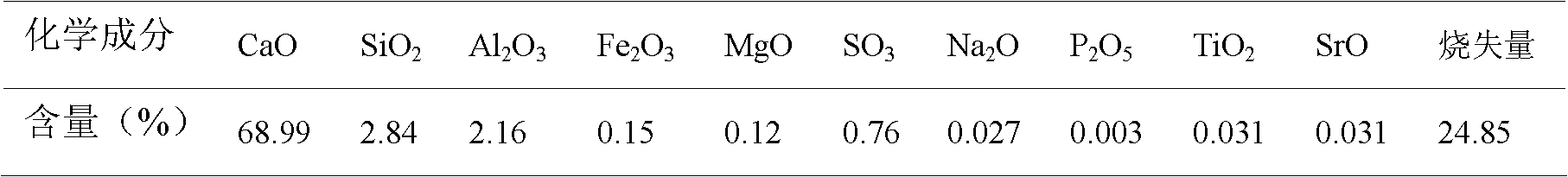

[0019] 2) Basic properties of carbide slag: the basic physical and chemical properties and chemical composition of the selected carbide slag are shown in Table 1 and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com