Cable for testing properties of battery pack

A technology for characteristic testing and battery packs, applied in the direction of cables with double-stranded/quad-stranded cables, etc., which can solve the problems that signals are susceptible to external electromagnetic noise interference, troublesome and time-consuming wiring and wiring, and external electromagnetic noise interference. , to achieve the effect of easy management and traceability of errors, saving time in wiring, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

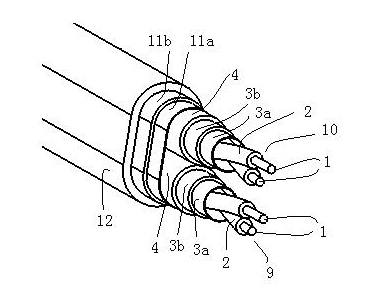

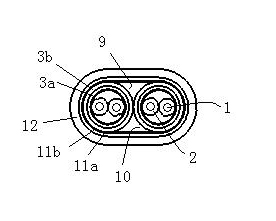

[0026] a kind of like Figure 1-2 The shown battery pack characteristic test cable includes a conductive core 1 inside the cable and an outer insulating sheath 12 covering the outer peripheral surface of the cable. The conductive core 1 is a single crystal copper conductor conductive core.

[0027] The conductive wire core 1 includes a voltage test line 9 and a temperature test line 10. The voltage test line 9 is used to transmit voltage signals, including battery DC voltage signals and small-amplitude excitation AC voltage signals; the temperature test line 10 is used to transmit temperature signals, including semiconductor Very low frequency small voltage signal provided by a temperature sensor.

[0028] There are two pairs of voltage test lines 9, and each voltage test line is a twisted wire structure of multiple conductive wires, and the outer circumference of a pair of voltage test lines 9 is coated with the inner shielding layer 3, and the outer circumference of the inn...

specific Embodiment approach 2

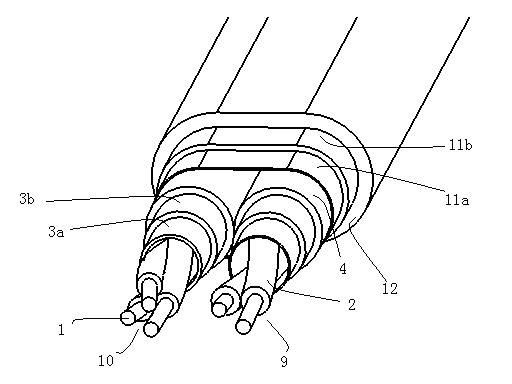

[0031] a kind of like Figure 3-4 The battery pack characteristic test cable shown is basically the same as the specific embodiment 1, the difference lies in:

[0032] The conductive wire core 1 is a single-crystal copper-plated conductor conductive wire core, and the temperature test wire 10 is a pair of three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com