Technology for decoloring refined mother liquor of monosodium glutamate with membrane method

A technology for mother liquor and monosodium glutamate, which is applied in the field of decolorization of monosodium glutamate refining mother liquor by membrane method, can solve the problems of aggravating the workload of decolorization process, the impact on the health of operators, and the low yield of monosodium glutamate refining, so as to reduce steam consumption and reduce equipment footprint. , the effect of refining cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

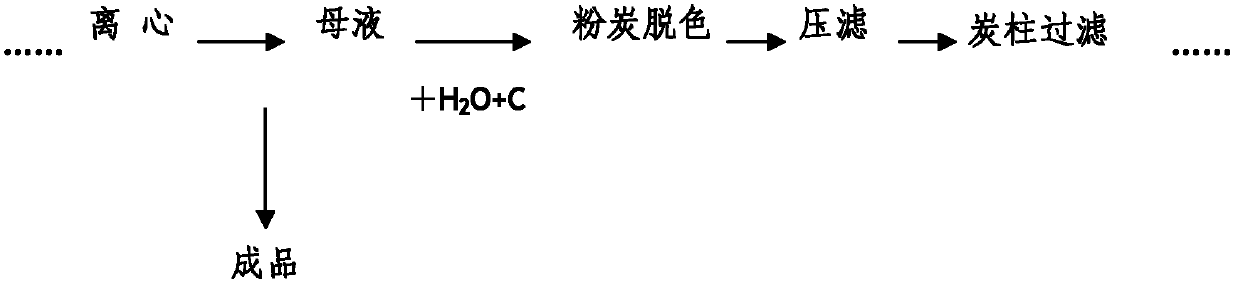

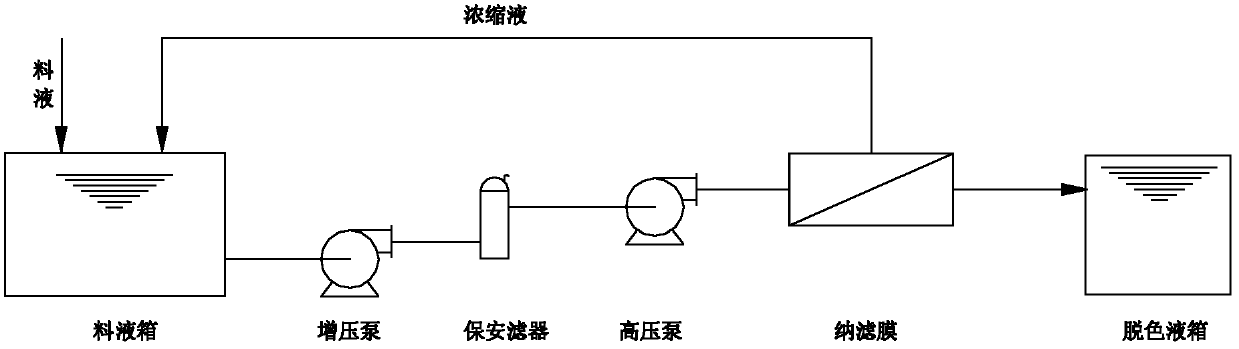

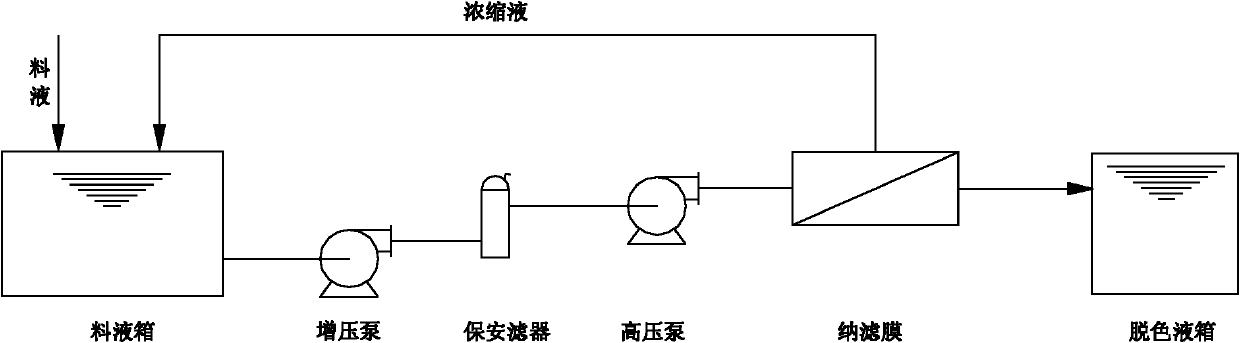

[0036] Refer to attached figure 2 .

[0037] 1. Transfer the secondary mother liquor (referred to as feed liquid) in the process of MSG refining to the feed liquid tank. Because the concentration of the feed liquid is high, the Baume degree is 28-30, it needs to be diluted with pure water to achieve the following indicators : The Baume degree is 23-24; the electrical conductivity is about 150000-350000 μs / cm; the light transmittance is 45%-55%, and the mass percentage content of sodium glutamate is 28%-34%.

[0038] 2. Due to the high temperature of the feed liquid, which reaches 60°C, it needs to be cooled. Natural cooling or heat exchanger cooling is adopted to cool down to 5-45°C, preferably 20°C-40°C.

[0039] 3. Put the diluted and cooled material liquid into the security filter with a booster pump to remove large particles with a diameter greater than 5 μm.

[0040] 4. After the feed liquid is filtered by the security filter, it is pumped into the nano-membrane decolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com