Combined type multifunctional experiment tower and experiment device thereof

An experimental tower and multi-functional technology, applied in the directions of distillation separation, dispersed particle separation, fractionation, etc., can solve the problems that are difficult to apply to field experimental research, experimental equipment is not suitable for movement, and cannot be compatible with the experimental process, etc., to achieve convenient conversion and practicality Strong and broaden the effect of experimental content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

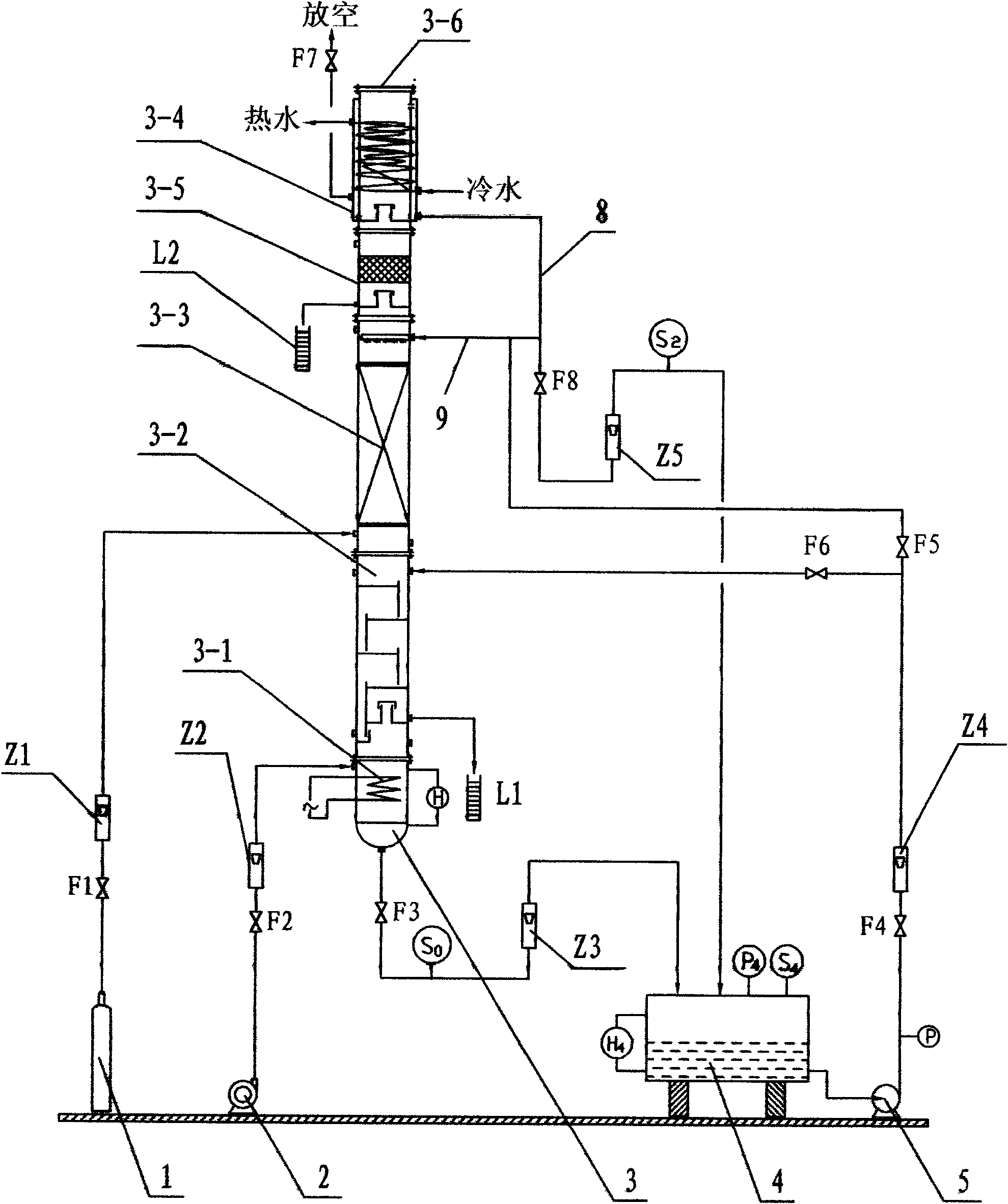

[0053] One, the concrete structure of combined multifunctional experimental tower of the present invention is as follows:

[0054] see figure 1 , 8 , the experimental tower consists of a tower kettle section 3-1, a plate tower section 3-2, a packed tower section 3-3, a condensation tower section 3-4, a mist entrainment test tower section 3-5 and several sealing plates 3-6 , 3-7 assembled.

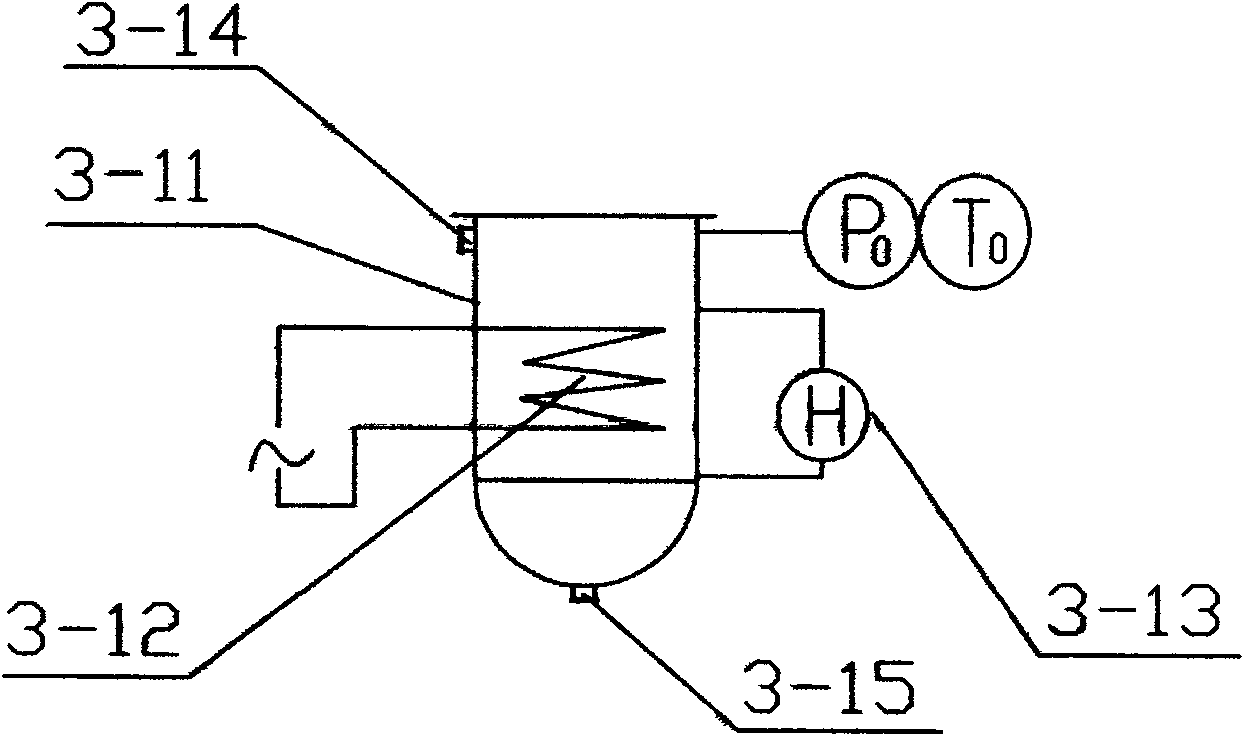

[0055] see figure 1 , 8 , 2. The tower still section 3-1 includes a tower still section shell 3-11, a heater 3-12 arranged in the tower still section shell, and a liquid level gauge 3-11 is provided on the tower still section shell 3-11 13. Tower kettle feed inlet 3-14, tower kettle discharge outlet 3-15 and tower kettle logistics detection point. The detection point of the stream in the tower kettle is mainly composed of the pressure measuring point P 0 and temperature measuring point T 0 Composition, other logistics inspection points may need to be set.

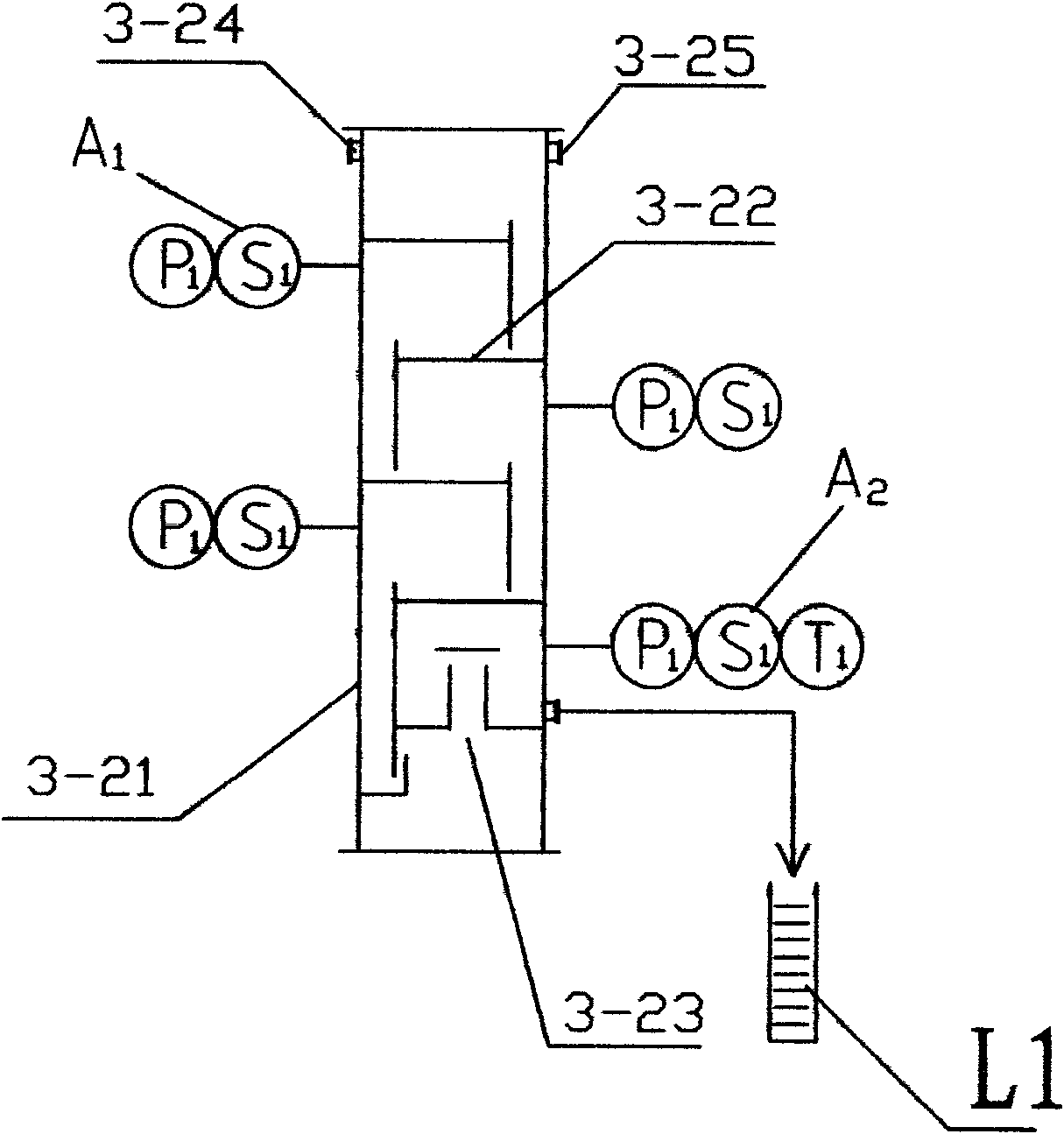

[0056] see figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com