Multiwire cutting machine dedicated to LEDs (light emitted diode)

A multi-wire cutting machine and metal cutting wire technology, which is applied in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of difficult cutting, difficult cutting, low wire breakage rate, etc. The effect of low wire rate and fast winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

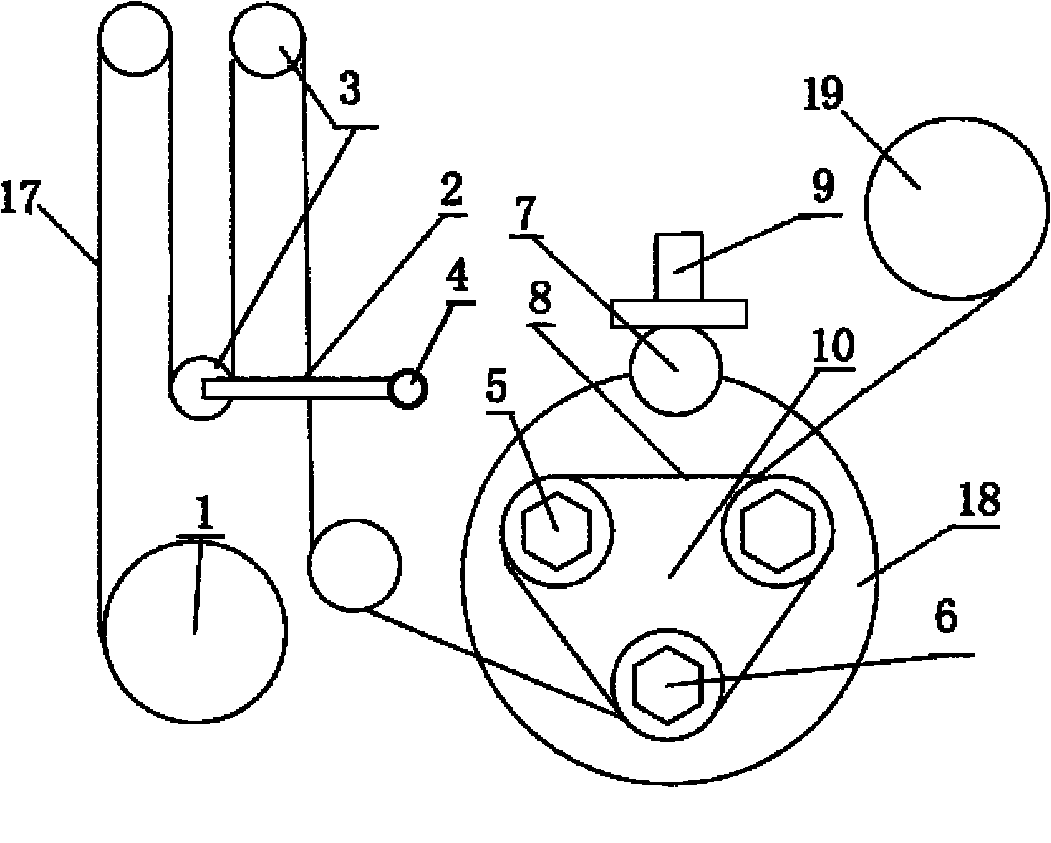

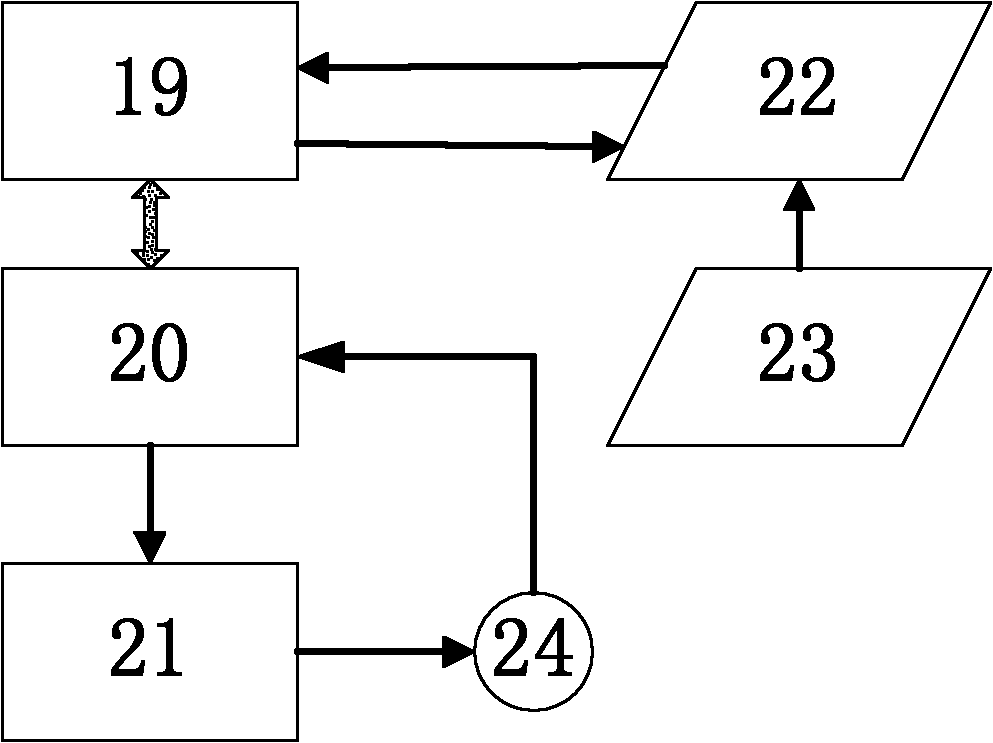

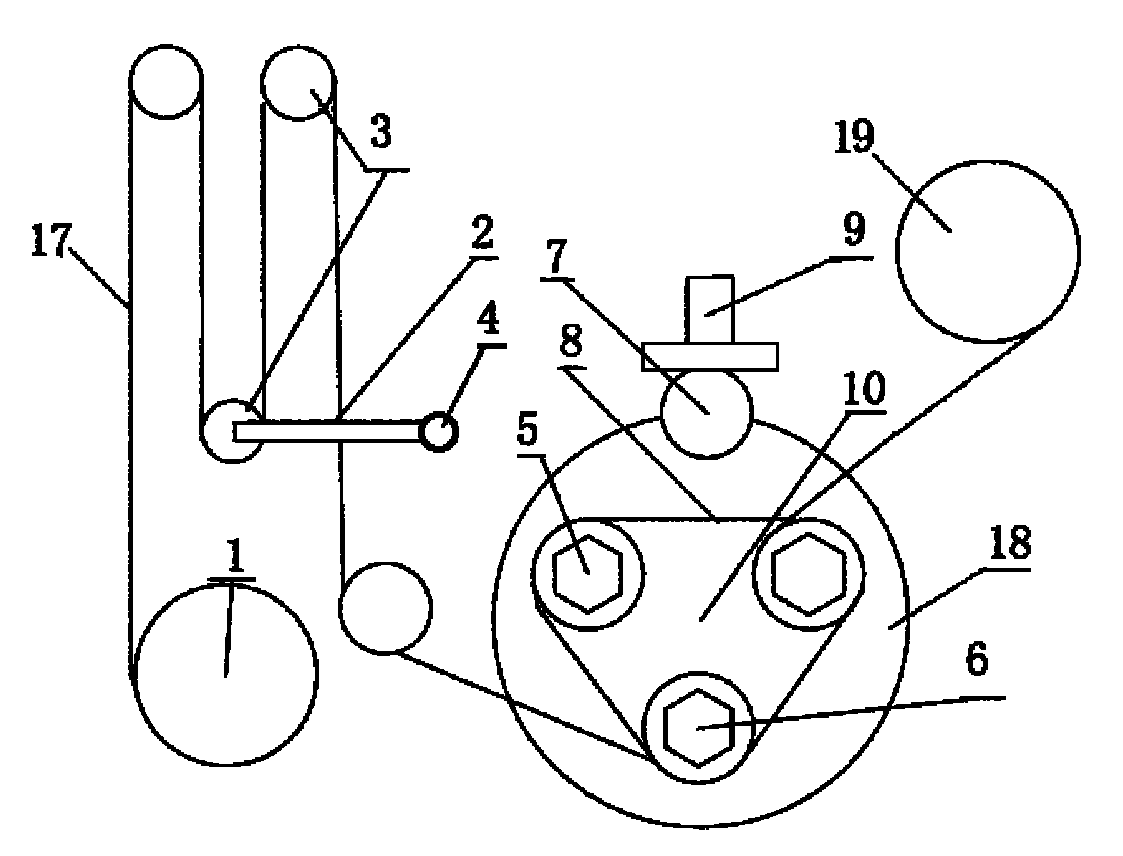

[0027] A special multi-wire cutting machine for LED, such as figure 1 As shown, it includes a workbench 9, a oscillating disk 18 arranged on one side of the workbench 9, and the oscillating disk 18 driven by a motor is provided with three processing rollers, and a metal cutting wire 17 is wound on the three processing rollers. One end of the metal cutting wire 17 is wound on a take-up wheel 19, and its other end is guided by four guide wheels 3 and wound on a pay-off wheel 1; one side of the guide wheel 3 is provided with an adjusting metal cutting wire 17 Tension pendulum bar 2 of tension, one end of this tension pendulum bar 2 is provided with tension motor 4, and wherein the key point of tension control is to keep the line speed of the whole winding system constant. The take-up reel 19 and the pay-off reel 1 are driven by a take-up and release reel motor 12 . Each of the guide wheels 3 is equipped with a tension sensor, and a controller 11 fine-tunes the rotation speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com