Stud gear with cutting edge and drill thereof

A cutting edge and column tooth technology, applied in drill bits, drill pipes, drill pipes, etc., can solve the problems of arranging slag discharge grooves to discharge slag or temporarily storing gravel, aggravating the wear of the steel carcass of the drill bit, and speeding up the wear speed of the column teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

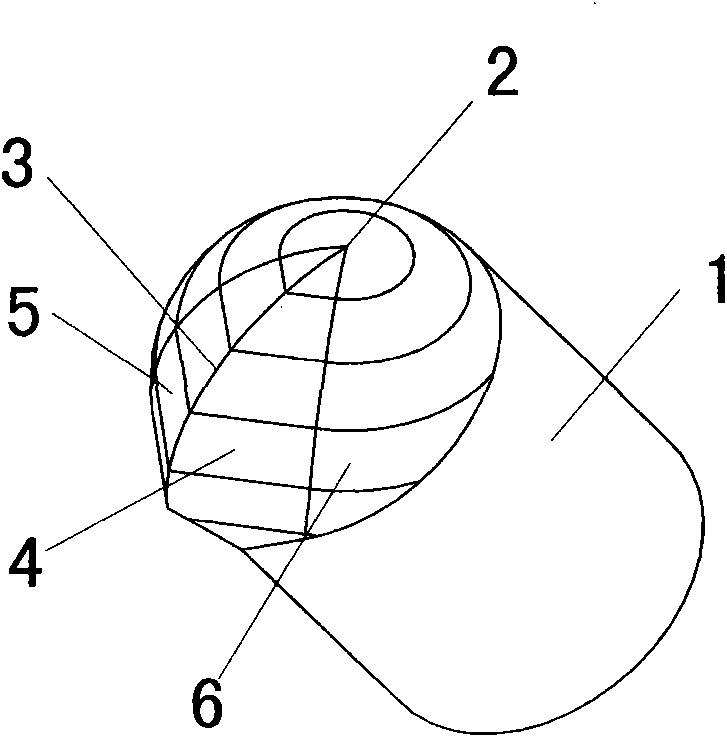

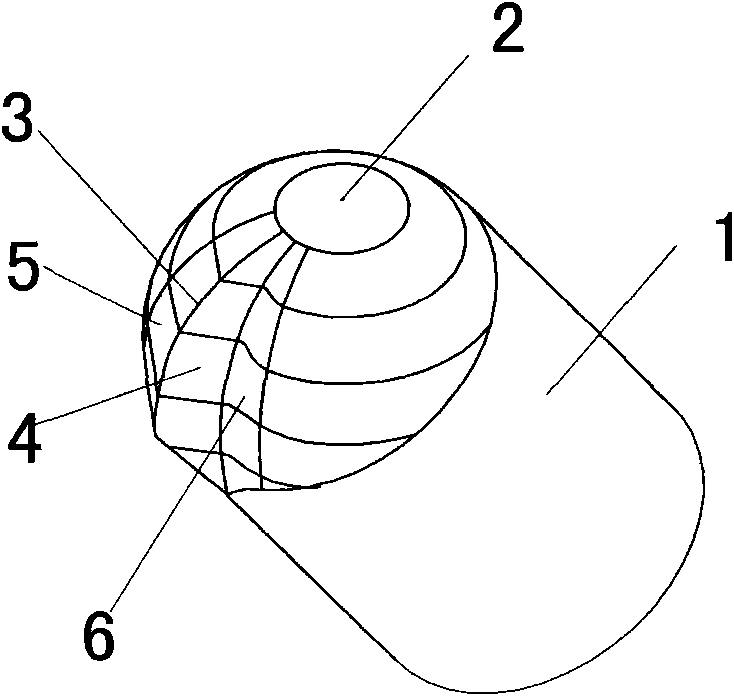

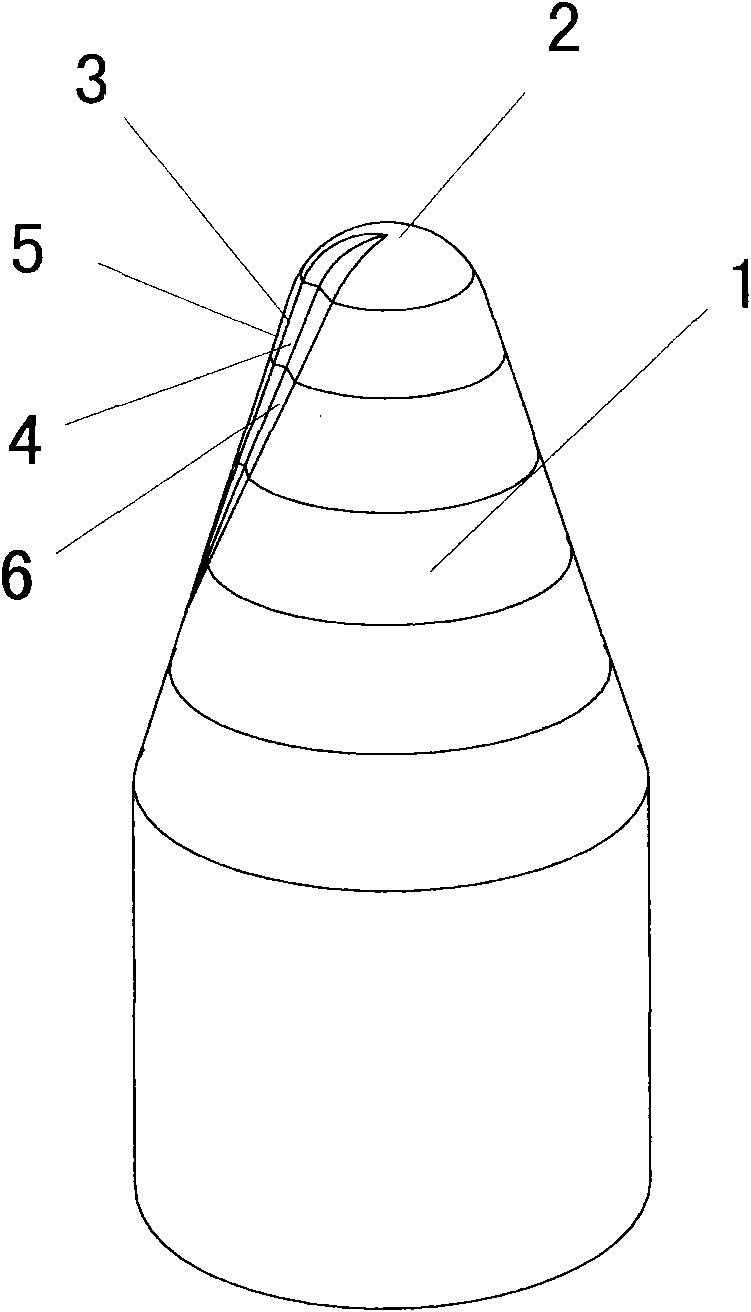

[0009] Such as figure 1 Shown is a side view of the ball stud gear shaft with a large cutting edge of the present invention, and its placement orientation is roughly the same as its installation orientation on the down-the-hole drill bit, that is, the impact head 2 faces upward, and the blade front 4 faces the reader , the same below, see Figure 17 . Among them, 1 is a column tooth, and its root shape is a cylinder; 2 is an impact head, which directly contacts the bottom of the well and breaks rock by impact when working on the down-the-hole drill bit; 3 is a cutting edge, which is in the When the down-the-hole bit rotates and works, it directly contacts the protruding corner of the well wall and breaks the rock by cutting; 4 is the front of the blade; The difference from the usual hemispherical head of the column tooth is that it is provided with a front edge 4 and a rear edge 5 that are gradually raised relative to the generatrix of the outer surface of the column tooth r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com