Spray drying system

A technology of drying system and spray drying tower, which is applied in the direction of drying solid materials, drying gas arrangement, drying, etc., and can solve the problem of unsuitable drying of lithium iron phosphate mixture suspension, poor fluidity of lithium iron phosphate mixture, and no exhaust waste heat Use and other problems to achieve good effect of bag cleaning, ensure product purity, and prevent precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

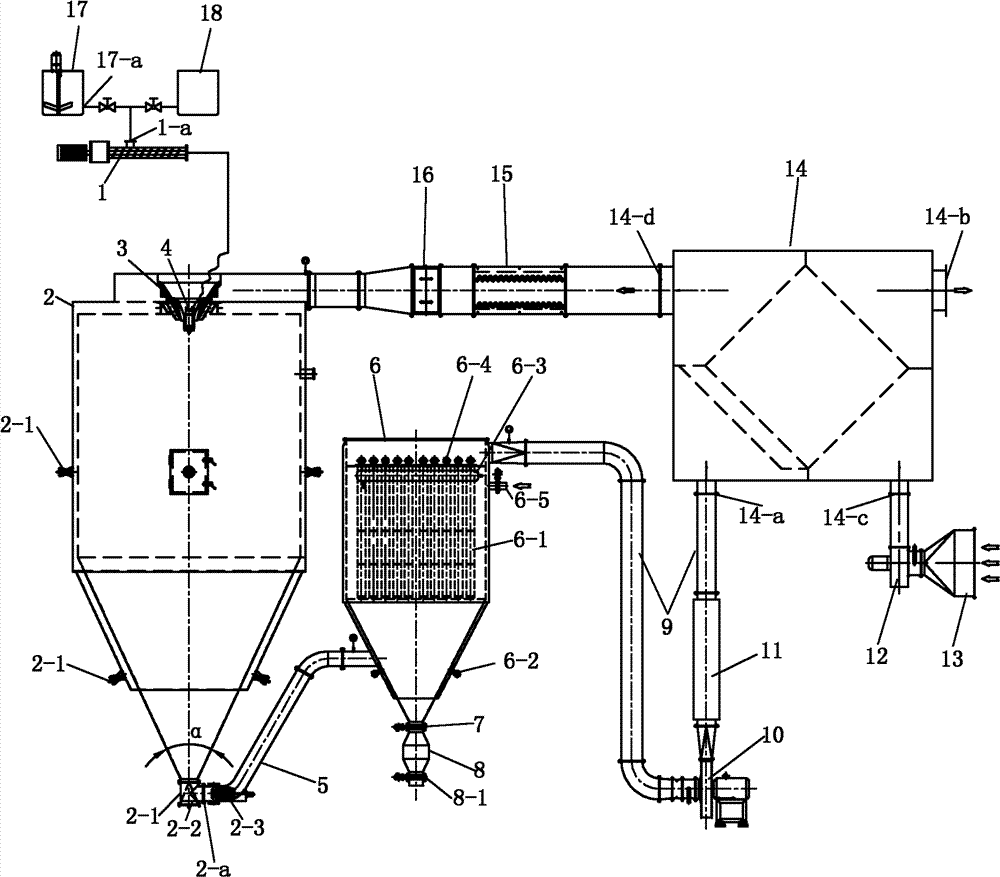

[0024] As shown in the drawings, this embodiment includes a feed pump 1 , a spray drying tower 2 , a pulse bag filter 6 , a heat exchanger 14 , an air heater 15 , a demagnetization stirring tank 17 and a water tank 18 .

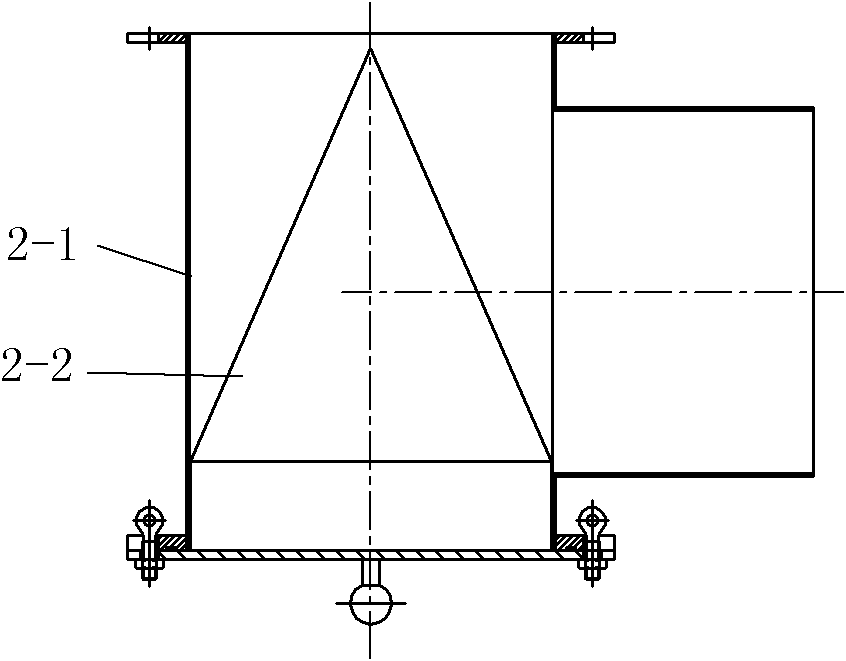

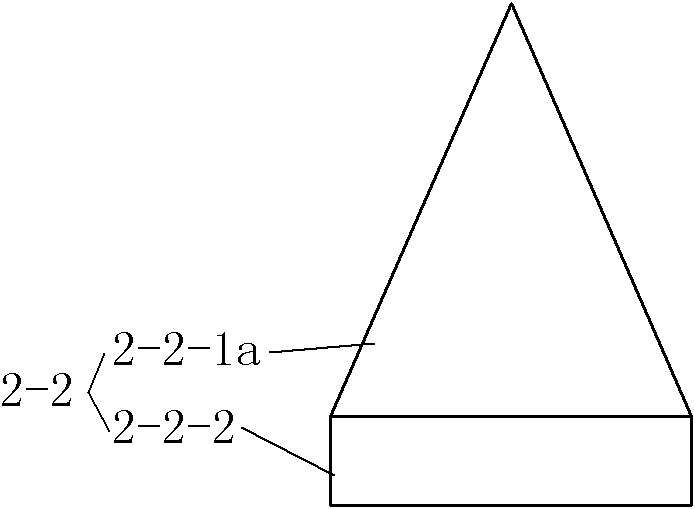

[0025] The central hot air inlet at the top of the drying tower 2 is provided with a hot air distributor 3 and an atomizer 4 installed in the center of the hot air distributor 3 and connected to the feed pump 1. The atomizer 4 is directly driven by a motor for atomization. The hole of the atomizing disc is embedded with a corrosion-resistant and wear-resistant zirconia sleeve. The zirconia sleeve can be replaced after wear, and there is no need to replace the atomizing disc. The hot air distributor 3 adopts the volute spiral sinking type, which can prevent the dry powder from being reversed. The inner wall of the spray drying tower 2 adopts a stainless steel mirror panel. The feeding cone angle α of the drying chamber in the spray drying tower is 50 degrees,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com