Automatic testing device with reverser motor rotor winding

An automatic test device and commutator motor technology, which is applied in the testing of motor generators, measuring devices, mechanical parts, etc., can solve the error of test results, the rotor commutator cannot be automatically cleaned, and the motor rotor cannot be continuously tested. problems such as testing, to achieve the effect of cleaning up thoroughly, reducing the false detection rate and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

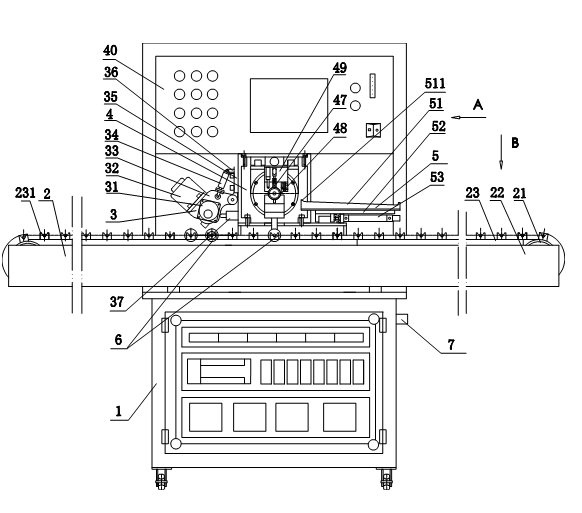

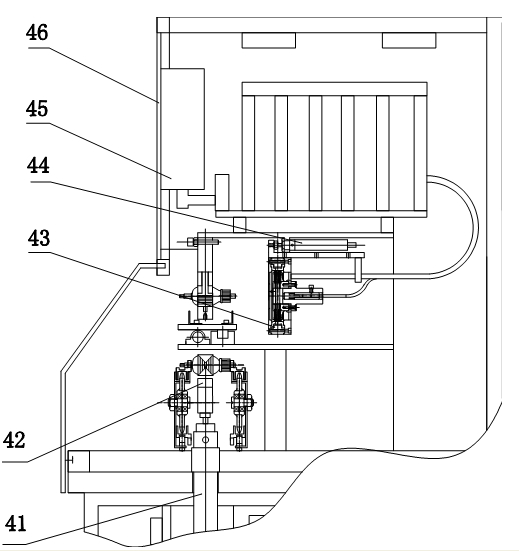

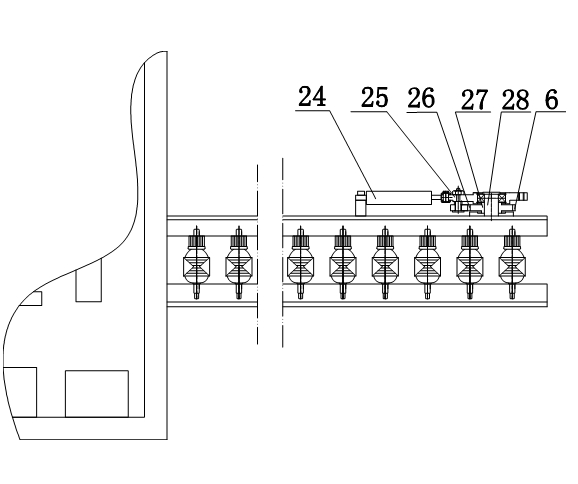

[0023] Embodiment 1: as figure 1 As shown, an automatic testing device for motor rotors with a commutator includes a machine base 1, casters are provided under the machine base, a workpiece transfer device 2 for transmitting the motor rotor and a comprehensive test bench 40 are arranged on the machine base, and the comprehensive test bench A comprehensive testing device 4 is provided on the comprehensive testing device 4, and a workpiece performance comprehensive testing instrument 45 and an electrical controller 46 including a computer system are arranged on the comprehensive testing device 4. The electrical controller is provided with a digital display device, and on one side of the comprehensive testing device 4 An automatic cleaning device 3 for the motor rotor commutator is provided, and a defective product sorting device 5 is provided on the other side of the comprehensive testing device 4. At the end of the automatic cleaning device 3, the comprehensive testing device 4 ...

Embodiment 2

[0028] Embodiment 2: The toothed ratchet device in Embodiment 1 is replaced by a ratchet device with two pawls, which can achieve the effect that the argument angle of rotation can be changed at the level of half teeth, that is, the distance that the chain can move each time can be divided into half teeth. Adjustment, this structure is beneficial to move the motor rotor to the set working position more accurately.

[0029] Dimples are arranged on the two bearing surfaces of the V-shaped seat carrying the motor rotor, rollers are arranged in the dimples, and the outer circular surface of the rollers is used to carry the motor rotor, so that the friction force of the motor rotor is small when rotating.

Embodiment 3

[0030] Embodiment 3: The toothed ratchet device in Embodiment 1 is replaced by a silent ratchet device, which can achieve the effect of stepless change in the argument of rotation, that is, the distance that the chain moves each time can be adjusted arbitrarily. This structure is conducive to making the motor The rotor moves very precisely to the set working position.

[0031] Miniature rolling bearings are arranged on the two bearing surfaces of the V-shaped seat bearing the motor rotor, and the outer circular surface of the rolling bearing is used to carry the motor rotor, so that the friction force of the motor rotor is extremely small when rotating.

[0032] On the bracket of the workpiece conveying device, a pair of infrared position sensing devices are added, and an audible and visual alarm device is provided. When the rotor of the motor passing the test is delivered to this position, an alarm can be given in advance without stopping the machine. The infrared ray The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com