Non-aqueous electrolyte secondary cell

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, secondary batteries, electrolytes, etc., can solve the problem of not being able to sacrifice battery discharge characteristics, and achieve the effect of improving safety and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

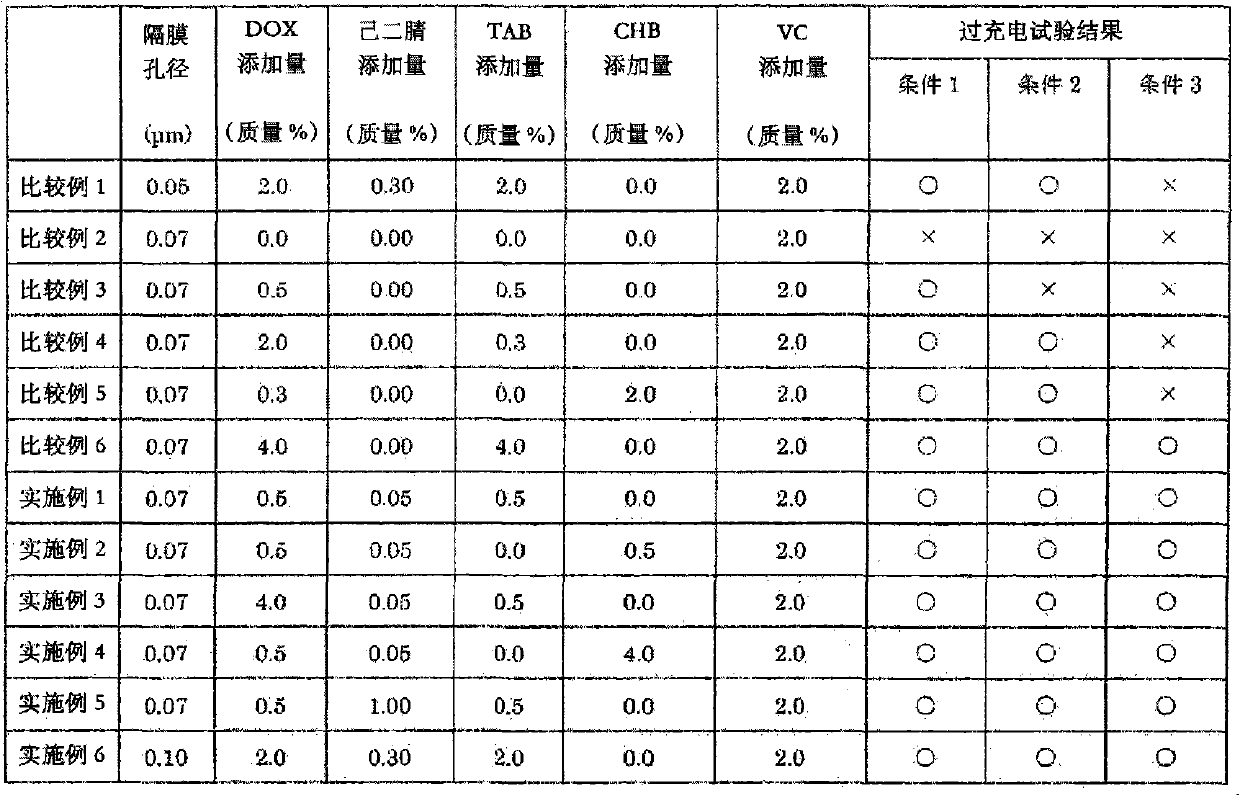

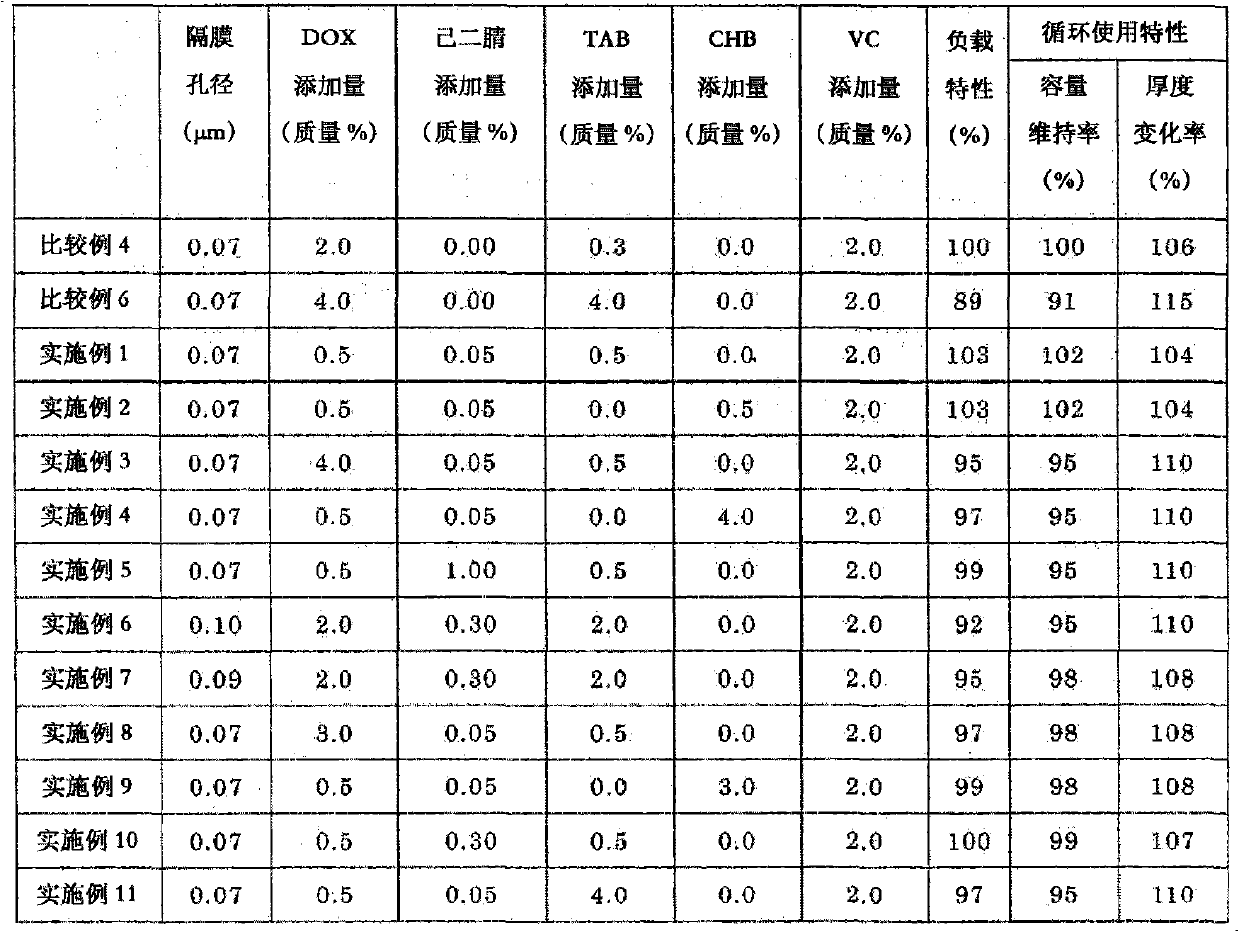

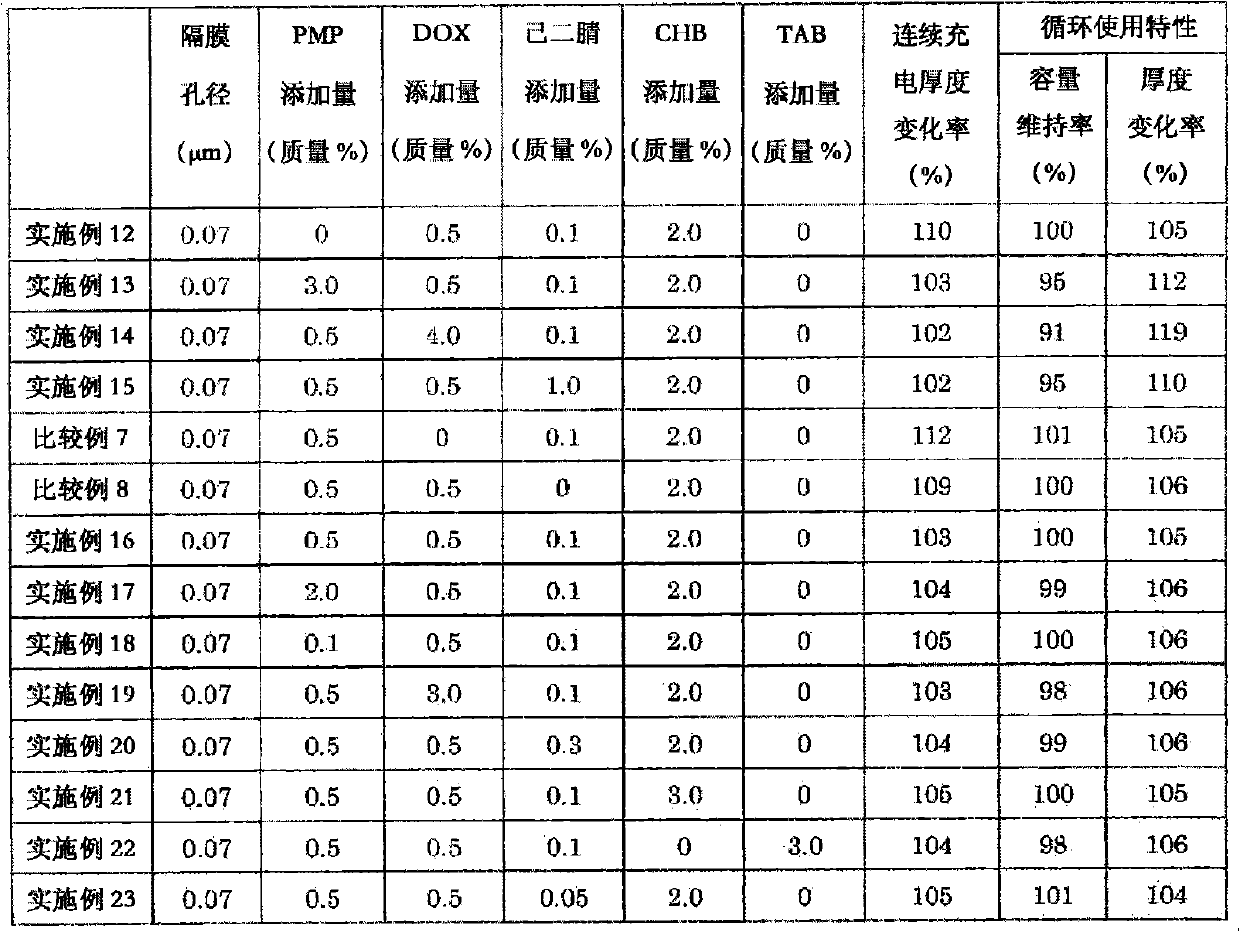

Examples

Embodiment 1

[0047]

[0048] When cobalt carbonate is synthesized, 0.15 mol% of zirconium and 0.5 mol% of magnesium are coprecipitated relative to cobalt, and thermal decomposition reaction occurs to obtain tricobalt tetroxide containing zirconium and magnesium. Lithium carbonate as a lithium source was mixed therein and fired at 850°C for 24 hours to obtain lithium cobaltate (LiCoO) containing zirconium and magnesium. 0.9935 Zr 0.0015 Mg 0.005 o 2 ).

[0049] The above-mentioned lithium cobaltate containing zirconium and magnesium, carbon powder as a conductive agent, and polyvinylidene fluoride (PVdF) as a binder are mixed in a mass ratio of 94:3:3, and they are mixed with N-formazan Base-2-pyrrolidone (NMP) was mixed to prepare positive electrode active material slurry.

[0050] Then, using a doctor blade, this positive electrode active material slurry was applied to both surfaces of a positive electrode core made of strip-shaped aluminum foil (thickness 15 μm) with a uniform thic...

Embodiment 2

[0064] In addition to using the above electrolyte, 1,3-dioxane (DOX), adiponitrile, cyclohexylbenzene (CHB) and vinylene carbonate (VC) in a mass ratio of 96.95:0.5:0.05:0.5:2.0 A battery of Example 2 was fabricated in the same manner as in Example 1 above except for the nonaqueous electrolyte.

Embodiment 3

[0066] In addition to using the above electrolyte, 1,3-dioxane (DOX), adiponitrile, tert-amylbenzene (TAB) and vinylene carbonate (VC) in a mass ratio of 93.45:4.0:0.05:0.5:2.0 The battery of Example 3 was fabricated in the same manner as in Example 1 above except for the nonaqueous electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com