Microwave sintering method of clay-graphite crucible

A graphite crucible and microwave sintering technology, which is applied in the field of clay graphite crucible preparation, can solve the problems of low production efficiency and high labor intensity, and achieve the effects of short sintering time, improved utilization rate, and safe and pollution-free production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

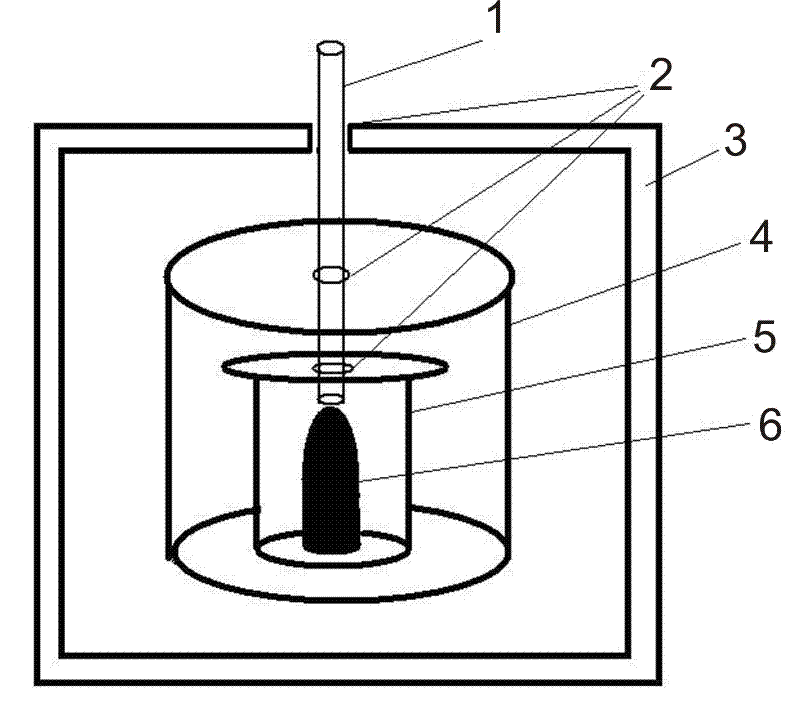

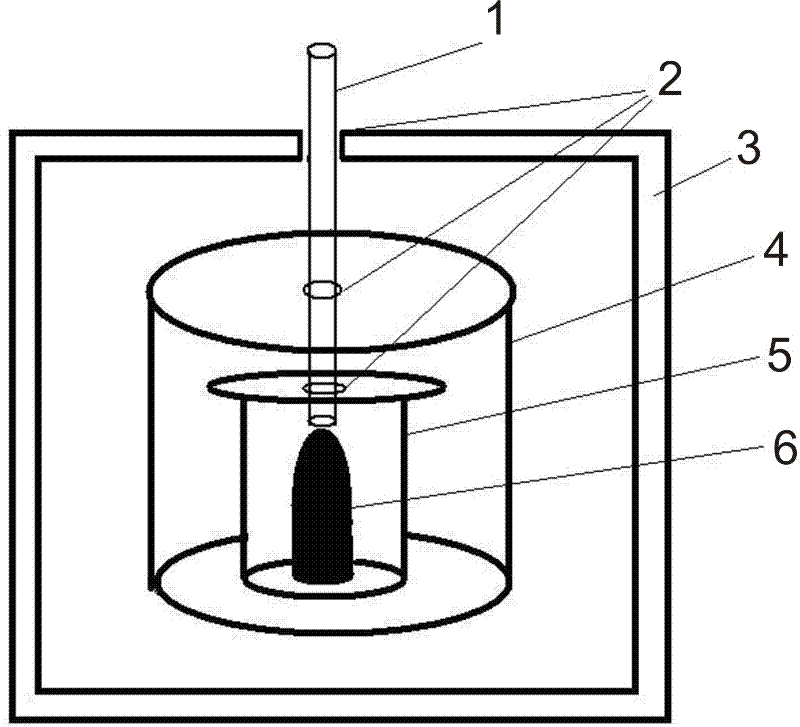

[0027] The clay and graphite are prepared according to the formula ratio, and then fully mixed and aged to obtain a mud material with good molding properties. Then 30g of mud is pressed into a small-volume model with the same proportion as the actual clay-graphite crucible product, and placed in a vacuum drying oven for low-temperature drying. After the drying is completed, glaze the outer surface of the sample 6 and dry it, put the dried sample 6 into the small corundum crucible 5, press figure 1 The medium structure is put into the microwave oven 3 for sintering, the microwave frequency is 2450HMz, the output power adjustment range is 500-2000W, and the temperature rise curve of the sample 6 is controlled appropriately, and the sintering time is 1.5h; after the sintering is completed, the sample 6 is cooled with the furnace. The completion of sintering was preliminarily judged by the amount of water loss, and then the strength and hardness of sample 6 after sintering were co...

Embodiment 2

[0029] The clay and graphite are prepared according to the formula ratio, and then fully mixed and aged to obtain a mud material with good molding properties. Then 50g of mud is pressed into a small-volume model with the same proportion as the actual clay-graphite crucible product, and placed in a vacuum drying oven for low-temperature drying. After the drying is completed, glaze the outer surface of the sample 6 and dry it, put the dried sample 6 into the small corundum crucible 5, press figure 1 The medium structure is put into the microwave oven 3 for sintering, the microwave frequency is 2450HMz, the output power adjustment range is 500-2000W, the temperature rise curve of the sample 6 is controlled properly, and the sintering time is 2h; after the sintering is completed, the sample 6 is cooled with the furnace. The completion of sintering was preliminarily judged by the amount of water loss, and then the strength and hardness of sample 6 after sintering were compared with...

Embodiment 3

[0031] The clay and graphite are prepared according to the formula ratio, and then fully mixed and aged to obtain a mud material with good molding properties. Then 100g of mud is pressed into a small-volume model with the same proportion as the actual clay-graphite crucible product, and placed in a vacuum drying oven for low-temperature drying. After the drying is completed, glaze the outer surface of the sample 6 and dry it, put the dried sample 6 into the small corundum crucible 5, press figure 1 The medium structure is put into the microwave oven 3 for sintering, the microwave frequency is 2450HMz, the output power adjustment range is 500-3000W, and the temperature rise curve of the sample 6 is controlled appropriately, and the sintering time is 1.5h; after the sintering is completed, the sample 6 is cooled with the furnace. The completion of sintering was preliminarily judged by the amount of water loss, and then the strength and hardness of sample 6 after sintering were c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com