Carbon fiber reinforced boron nitride composite and preparation method thereof

A technology of composite material and boron nitride, which is applied in the field of precursor converted carbon fiber reinforced boron nitride composite material and its preparation, to achieve the effects of simple preparation process, good processing performance and high ceramic conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

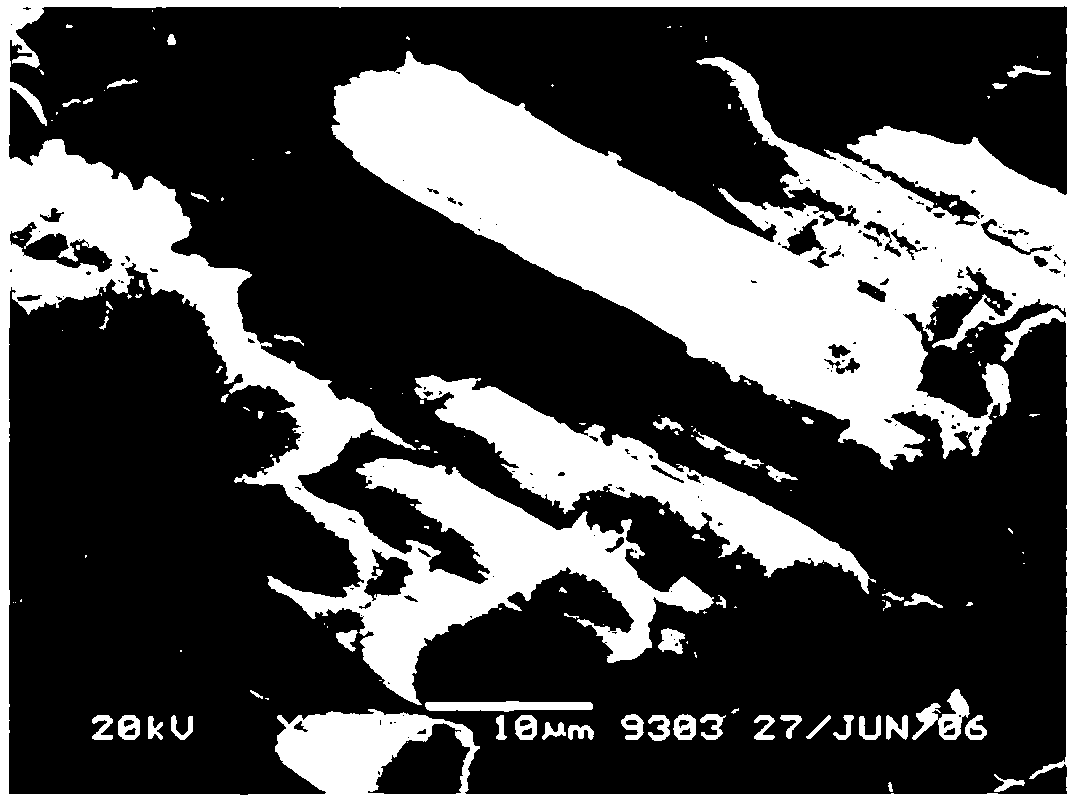

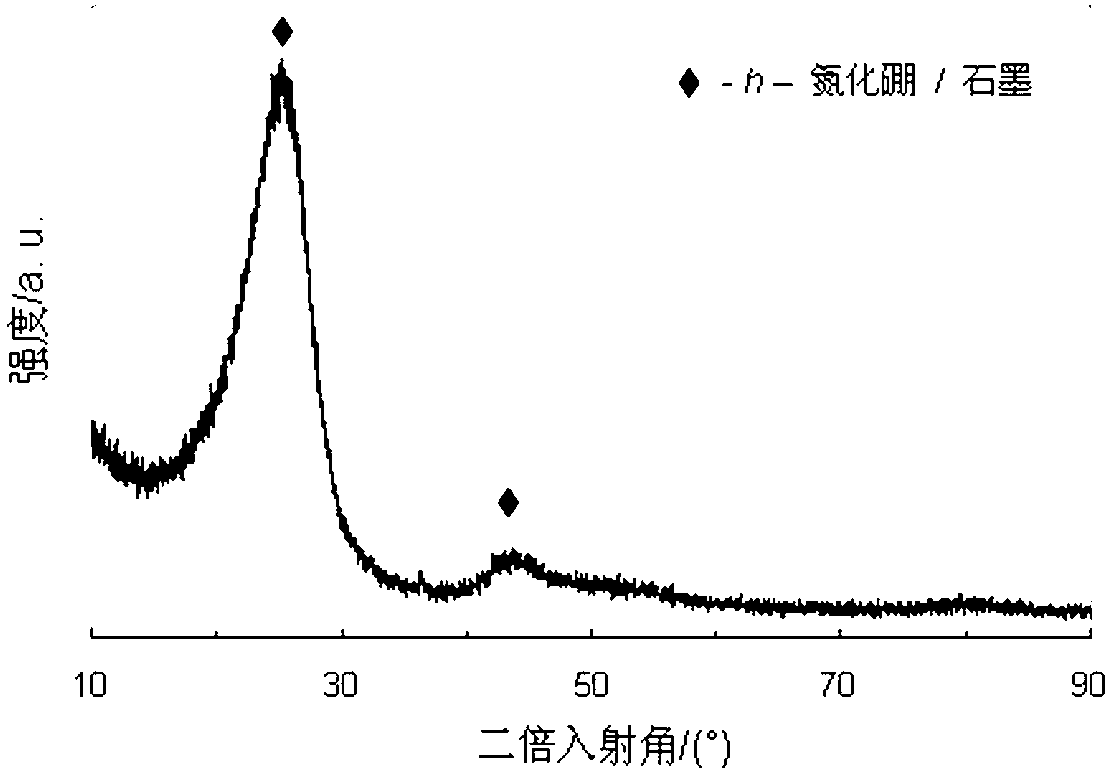

Image

Examples

Embodiment 1

[0020] Select T300 carbon fiber and weave it into a three-dimensional four-way structure three-dimensional fabric, in which the fiber volume fraction is 33%;

[0021] Put the fabric in a sealable container, vacuumize it, suck the liquid borazine into the container, and soak for 1 hour; the final impregnation amount is based on the liquid level being higher than the fabric;

[0022] Then place it in a closed autoclave with a pressure of 4MPa, heat it to 80°C under the protection of an inert atmosphere, and keep it warm for 55 hours to make the liquid borazine cross-linked and solidified;

[0023] Put the cured product in a vacuum cracking furnace at 1200°C, and keep it warm for 2 hours;

[0024] The above impregnation-crosslinking-cracking process was repeated for 3 cycles to obtain carbon fiber reinforced boron nitride composite material.

[0025] The performance of the three-dimensional four-way carbon fiber (T300) fabric reinforced boron nitride composite material prepared ...

Embodiment 2

[0028] a. Select T300 carbon fiber and weave it into a three-dimensional fabric with a 2.5-dimensional structure (between two-dimensional and three-dimensional), in which the fiber volume fraction is 40%.

[0029] b. Fully immerse borazine into the carbon fiber fabric under vacuum conditions, then place it in a closed autoclave (pressure 7MPa), heat it to 100°C under the protection of an inert atmosphere, and keep it warm for 35 hours to make the liquid borazine Joint curing;

[0030] a. Select T300 carbon fiber and weave it into a three-dimensional fabric with a 2.5D structure, in which the fiber volume fraction is 40%.

[0031] b. Fully immerse the borazine into the carbon fiber fabric under vacuum conditions, then place it in a closed autoclave, heat it to 100°C under the protection of an inert atmosphere, and keep it warm for 35 hours to crosslink and solidify the liquid borazine;

[0032] c. Place the cured product in a vacuum cracking furnace with a cracking temperature...

Embodiment 3

[0035] a. Select T700 carbon fiber and weave it into a three-dimensional five-dimensional fabric with a fiber volume fraction of 30%.

[0036] b. Fully immerse borazine into the carbon fiber fabric under vacuum conditions, then place it in a closed autoclave (pressure 4MPa), heat it to 100°C under the protection of an inert atmosphere, and keep it warm for 35 hours to make the liquid borazine Joint curing;

[0037] c. Place the cured product in a vacuum cracking furnace with a cracking temperature of 1500°C and keep it warm for 1 hour;

[0038] d. Repeat the impregnation-crosslinking-cracking process for 2 cycles to obtain a carbon fiber reinforced boron nitride composite material with relatively high porosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com