Method for preparing phenyl hypophosphite flame retardant

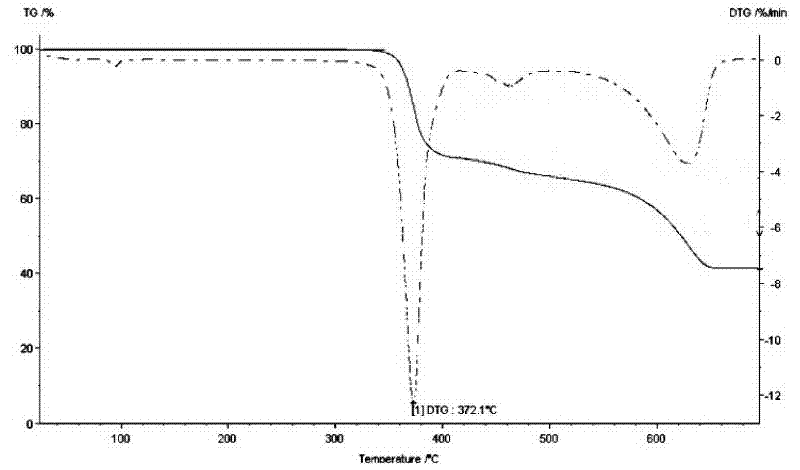

A technology of phenyl hypophosphite and flame retardant, which is applied in the field of preparation of phenyl hypophosphite flame retardant, can solve the problems of harsh conditions, cumbersome steps and high cost, and achieves short reaction period, good thermal stability, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A preparation method of phenyl hypophosphite flame retardant, comprising the steps of:

[0016] 1) In the reaction kettle with stirring, reflux device and acid absorption tower, add water at a temperature of 40-100 ° C, start stirring, N 2 protection, then add phenylphosphine dichloride to water within 1 to 6 hours, and keep stirring;

[0017] 2) After adding phenylphosphine dichloride, under stirring, keep the temperature at 40-100°C and keep the reaction for 1-6 hours;

[0018] 3) Cool down to room temperature, adjust the pH of the reaction solution to 6~8 with an alkaline substance, then add an inorganic metal salt within 0.5~3 hours, maintain the reaction for 1~2 hours, then filter and dry to obtain a phenyl hypophosphorous acid Salt flame retardant;

[0019] Among them, the volume of water: the amount of phenylphosphine dichloride: the amount of inorganic metal salt = 1L: (1~7mol): (1~5mol).

[0020] The alkaline substance is at least one of sodium hydroxide, po...

Embodiment 1

[0023] 1) Add 500ml of deionized water at 40~50°C in a 2L reaction kettle with stirring, reflux device and acid absorption tower, start stirring, N 2 Protection, dropwise add 2mol of phenyl phosphorus dichloride in 1~2 hours, and keep stirring;

[0024] 2) After adding phenylphosphine dichloride, under stirring, keep the temperature at 90-100°C and keep the reaction for 1-2 hours;

[0025] 3) Cool down to room temperature, adjust the pH of the reaction solution to 6~8 with 20% NaOH solution, and then add 0.8molAlCl in 0.5~1h 3 Solute, AlCl with a mass fraction of 30% 3 Solution, maintain reaction for 1-2 hours, then filter and dry to obtain a phenyl hypophosphite flame retardant.

Embodiment 2

[0027] 1) In a 5L reaction kettle with stirring, reflux device and acid absorption tower, add 1000ml deionized water at 40~50°C, start stirring, N 2 For protection, 6mol of phenylphosphorous dichloride was added dropwise within 3 to 4 hours;

[0028] 2) After adding phenylphosphine dichloride, under stirring, keep the temperature at 90-100°C and keep the reaction for 3-5 hours;

[0029] 3) Cool down to room temperature, adjust the pH of the reaction solution to 6~8 with 20% KOH solution, and then add 2mol solute with a mass fraction of 30% AlCl within 0.5~1h 3 Solution, maintain reaction for 1-2 hours, then filter and dry to obtain a phenyl hypophosphite flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com