Method for preparing oligomeric sialic acid

A polysialic acid and solution technology, applied in the field of bioengineering, can solve the problems of difficult control of reaction system temperature, difficult control, serious pollution, etc., and achieve the effects of convenient hydrolysis reaction, energy saving and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

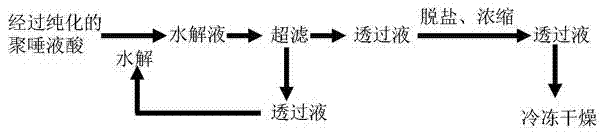

Image

Examples

Embodiment 1

[0022] Example 1: Hydrolysis of polysialic acid

[0023] Take 100g of polymerized sialic acid, dissolve it in 1L of 50mM NaOAc solution (the pH of the solution is adjusted to pH 4.7 with anhydrous acetic acid), and hydrolyze at 65°C for 2 hours.

Embodiment 2

[0024] Embodiment 2: the hydrolysis of polysialic acid

[0025] Take 100g of polymerized sialic acid, dissolve it in 0.5L of 50mM NaOAc solution (the pH of the solution is adjusted to pH 4.7 with anhydrous acetic acid), and hydrolyze at 60°C for 3 hours.

Embodiment 3

[0026] Embodiment 3: Extraction of oligosialic acid

[0027] A membrane with a molecular weight cut-off of 8000 is selected for separation by a hollow roll membrane separation method. The operating pressure is 0.5MPa. The reaction mixture is pushed through the membrane with 2.5-5L pH4.7 50mM NaOAc solution, and the ultrafiltration time is 25 minutes. The retentate continues to be used for hydrolysis. The hydrolysis process is operated according to hydrolysis at 60°C for 30 minutes and ultrafiltration for 25 minutes. Ultrafiltration is carried out according to the volume ratio of 1:5-10. Concentration of the permeate is carried out with a desalination membrane with a molecular weight cut off of 400, the operating pressure is 0.5 MPa, and the ultrafiltration time is 30 minutes. The intercepted concentrated solution is subjected to freeze-drying to obtain an oligomeric sialic acid product with a degree of polymerization of 2-10. The product yield rate is above 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com