Marine halomonas for producing low-temperature beta-galactosidase and application thereof

A technology of galactosidase and Halomonas, applied in the preparation of low-lactose milk, in the field of production of low-temperature β-galactosidase, can solve the problem of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

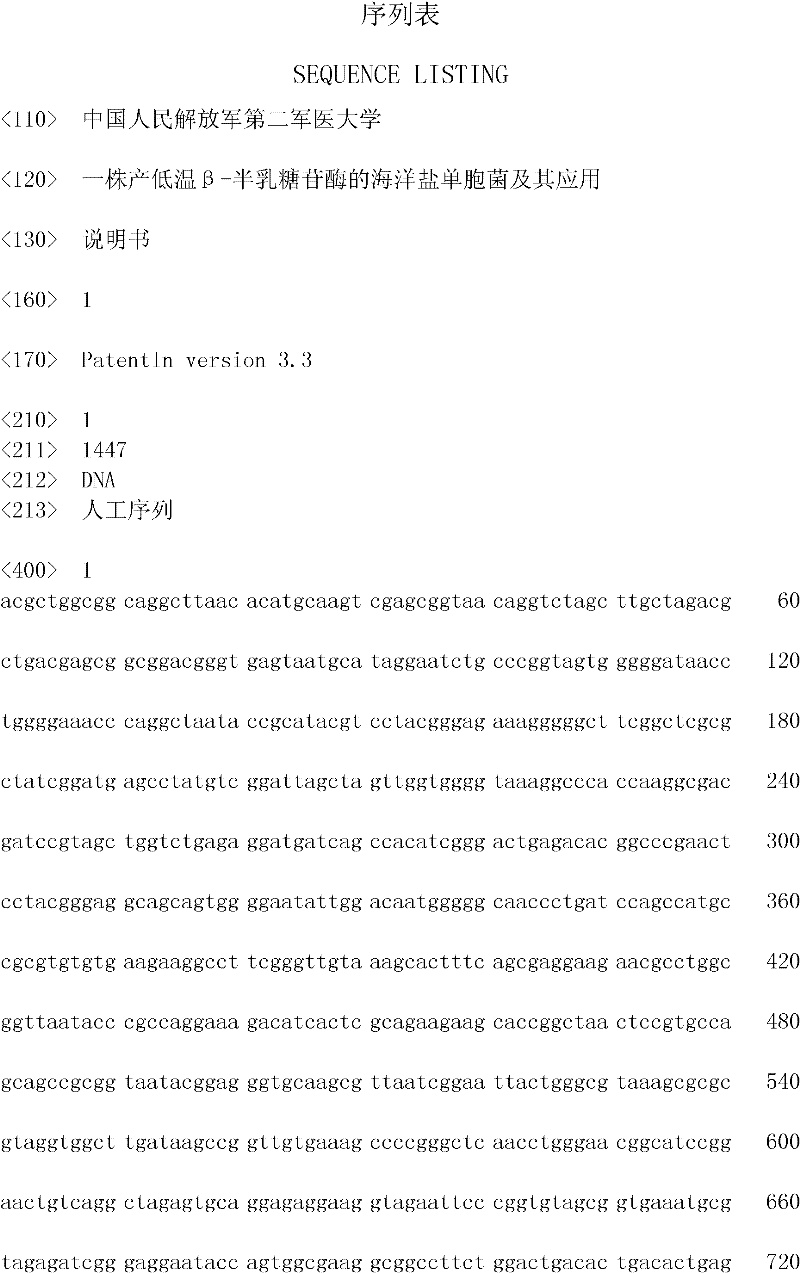

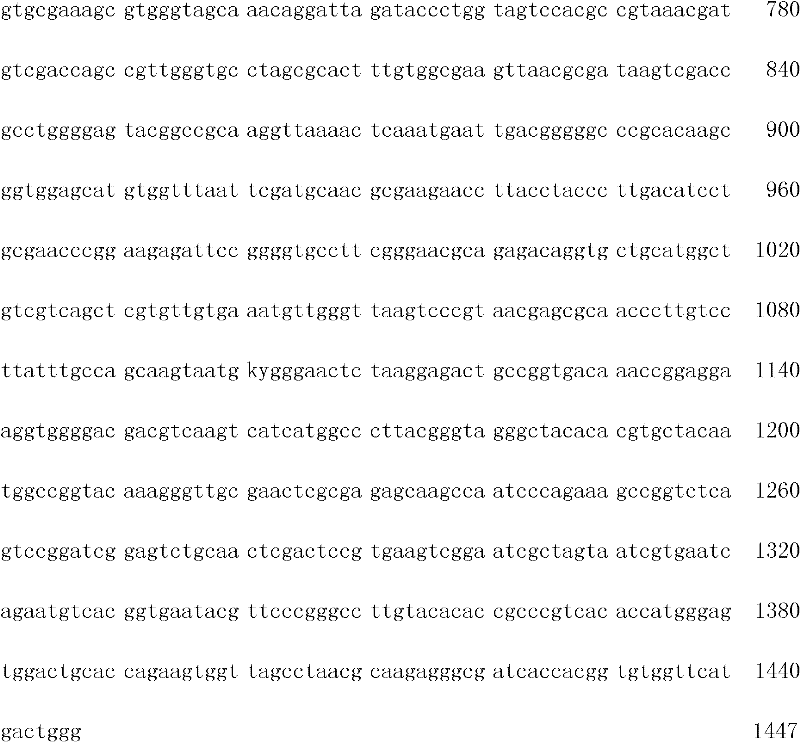

Image

Examples

Embodiment 1

[0017] Embodiment 1: the cultivation of bacterial strain P6009-1

[0018] The culture medium of bacterial strain P6009-1 is: peptone 5g, yeast extract 1g, iron phosphate 0.1g, artificial seawater (or old seawater) 1000ml, pH 7.6. Artificial seawater formula: NaCl 25.0g, NaCl 2 SO 4 4.0g, KCl 0.7g, NaHCO 3 0.20g, KBr 0.10g, H 3 BO 3 0.03g, NaF 0.003g, 53mL 1.0mol / LMgCl 2 solution, 10mL 1.0mol / l CaCl 2 Solution, 0.90ml 0.1mol / L SrCl 2 Solution, distilled water 1000ml, pH adjusted to 6.5. The strain P6009-1 was routinely inoculated in the culture medium and cultured at 28°C.

Embodiment 2

[0019] Embodiment 2: the crude enzyme liquid preparation of bacterial strain P6009-1

[0020] Lactose-induced culture was used to inoculate the P6009-1 strain in Zobell 2216E liquid medium (peptone 5g, yeast extract 1g, iron phosphate 0.1g, NaCl 60g, 1000ml distilled water, pH7.6), 28°C, 130r / min shaker culture After 2 days, the strain was activated, and then transferred to a fermentation liquid medium (lactose 20g, peptone 5g, yeast extract 1g, iron phosphate 0.1g) for culture, 28°C, 130r / min shaker culture for 3 days, and the fermentation broth was centrifuged at 5000r / min. min×15min×4°C, discard the supernatant. Resuspend the pellet with 0.05mol / L pH7.2 phosphate buffer, transfer to a centrifuge tube, wash the cells twice with phosphate buffer, and centrifuge at 5000r / min×15min×4°C, discard the supernatant. The bacteria were resuspended in 0.05mol / L pH7.2 phosphate buffer. Cells were disrupted with an ultrasonic pulverizer in an ice bath: sonicate for 1 s each time, and s...

Embodiment 3

[0021] Embodiment 3: the influence of metal ion on crude enzyme activity

[0022] Take 10 μL of crude enzyme solution, add 87 μL of 20g / L lactose, and then add 3 μL of 0.2M MnCl 2 , FeCl 2 , FeCl 3 , MgCl 2 , ZnCl 2 , LiCl, CoCl 2 , BaCl 2 , SrCl 2 , CuCl 2 , NaCl, CaCl 2 The solution was incubated at different temperatures, and whether the lactose was decomposed into galactose and glucose was detected by thin-layer chromatography. The specific operation was as follows: take 5 μL of the reaction solution and spot it on a silica gel thin-layer plate with a capillary tube, and use n-butanol: Pyridine: water (5:4:1) was used as the developing agent for development. When the front of the solvent reached about 1 cm away from the edge of the thin-layer plate, take out the thin-layer plate, evaporate the solvent, and spray 20% sulfuric acid-methanol solution, 115 ° C Bake color. With 0.2% lactose, 0.2% galactose, and 0.2% glucose as the standard reference substance, observe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com