Multi-layer composite sensitive film optical fiber hydrogen sensing probe and manufacturing method thereof

A multi-layer composite and sensing probe technology, which is applied in coating, metal material coating process, and material analysis through optical means, can solve the problems of poor mechanical stability of Pd film and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

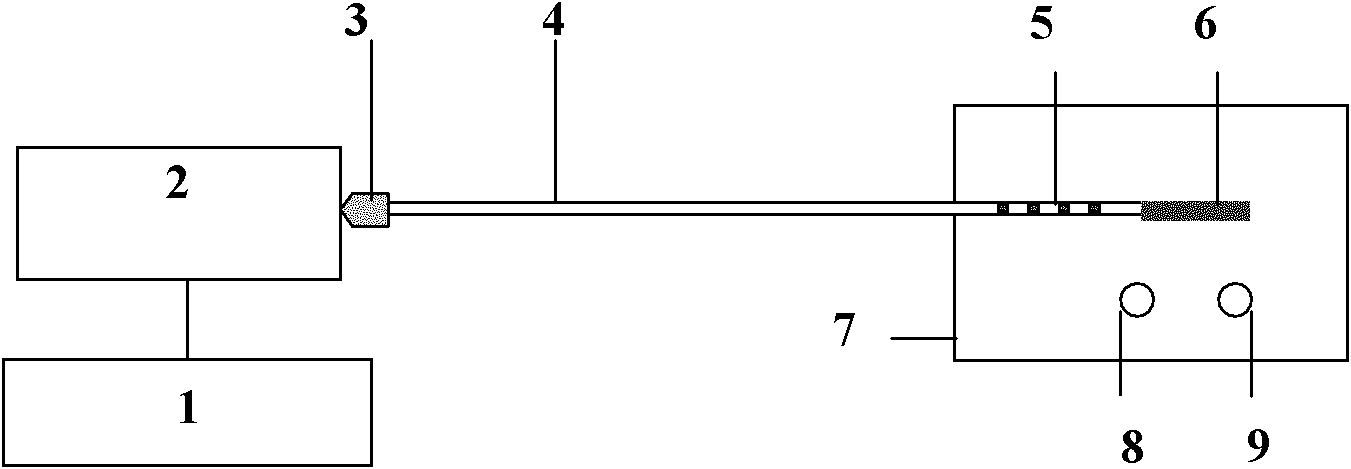

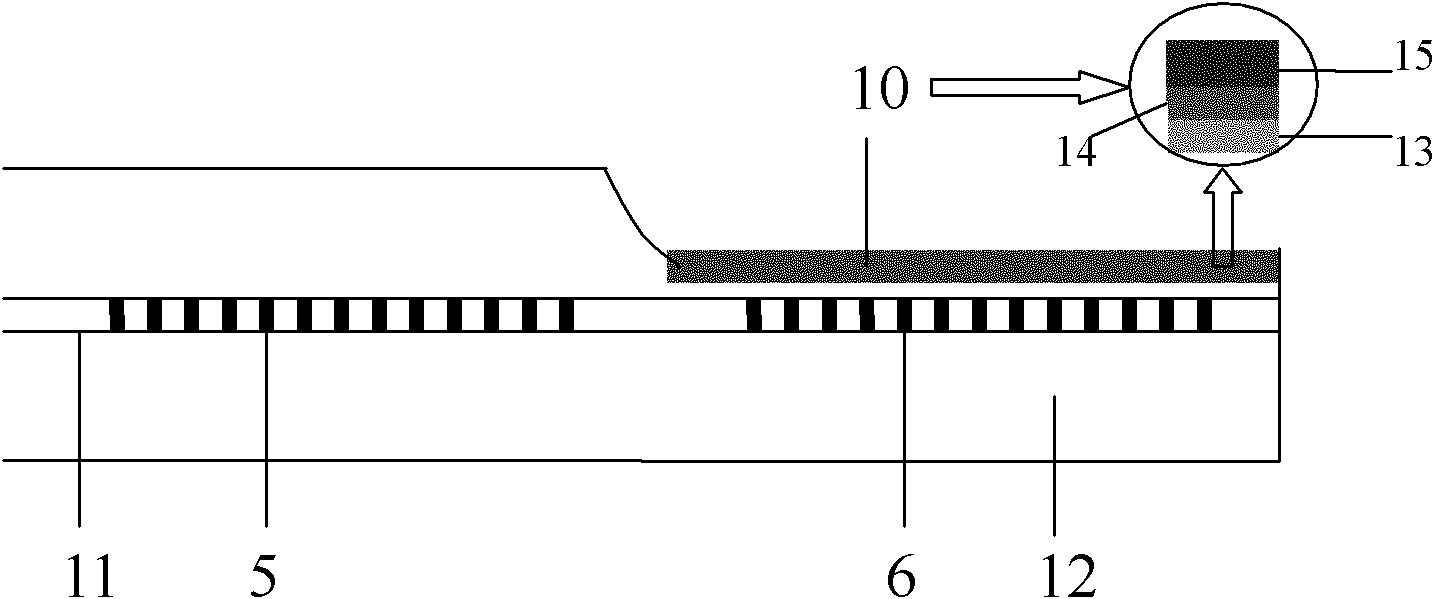

[0028] The embodiment of the multi-layer composite sensitive film optical fiber hydrogen sensing probe of the present invention will be further described below with reference to the accompanying drawings.

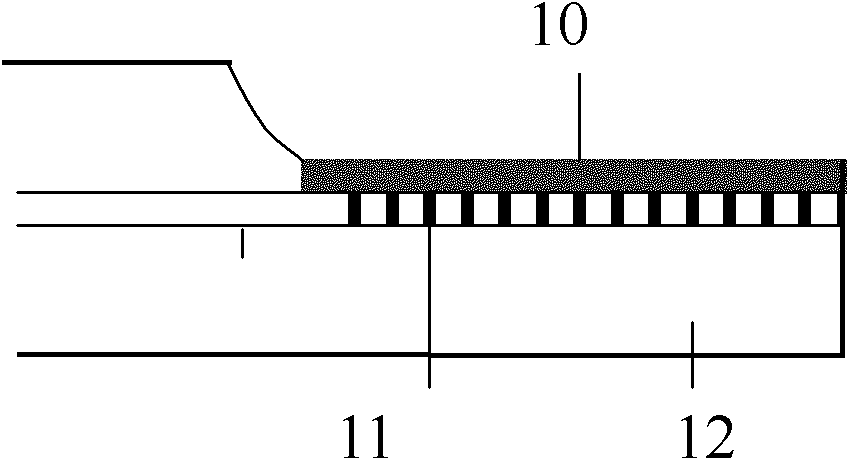

[0029] The multilayer composite sensitive film optical fiber hydrogen sensing probe structure of the present invention is as follows figure 2 As shown, the probe is composed of a D-type fiber grating 6 coated (sputtered) with a hydrogen sensitive film 10 and an uncoated reference grating 5 with a similar central wavelength, butt welded together; the hydrogen sensitive film 10 is made of SiO 2 Film 13, SiO 2 It is composed of a mixed film 14 with Pd and a thin 15 film of Pd.

[0030] The phase mask method is used to prepare two fiber gratings with similar center wavelengths from a single-mode fiber. One serves as the reference grating 5 for temperature compensation; the other is made into a D-type fiber grating 6 (sensing grating), which serves as a sensitive probe. In order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com