Conductive polymer composition and overcurrent protection element made from same

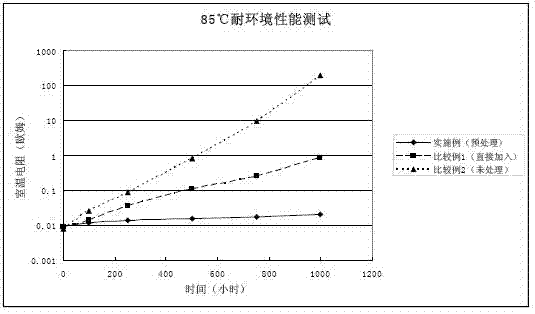

A technology of conductive polymers and compositions, applied in conductive materials dispersed in non-conductive inorganic materials, resistors with positive temperature coefficients, etc., can solve the problem of poor environmental resistance, low room temperature resistance, and low room temperature resistivity and other problems, to achieve the effect of excellent environmental resistance and low room temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Each component is proportioned according to Table 1:

[0046]

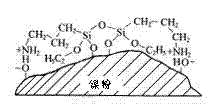

[0047] Immerse the nickel powder CNP525 in Table 1 in the ethanol solution of silane coupling agent KBE903, stir with a dry mixer for 30 minutes, and place it in a vacuum oven (vacuum degree: 10 -1 MPa, temperature 25°C) to remove ethanol by drying for 24 hours to obtain anti-oxidation treated nickel powder.

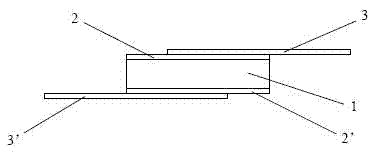

[0048] Put the treated nickel powder, high-density polyethylene and EVA wax into the internal mixer in turn, mix evenly at 190°C, pull out a sheet with a thickness of about 0.65mm on the open mixer, and cut it into 200mm×200mm The core material 1, put a piece of metal foil 2, 2' on the upper and lower sides respectively, and press it into a composite chip with a thickness of about 0.6mm on a press at 180°C. The composite chip is irradiated with an electron beam, and the irradiation dose is 10 Mrad to 100 Mrad. Then this chip is punched or cut into chips of 3mm * 4mm, and a nickel sheet with a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com