Ceramic composition, ceramic sintered body, laminated ceramic electronic component and method for preparing same

A technology of composition and sintered body, which is applied in the direction of electrical components, circuits, resistors, etc., to achieve the effect of reducing room temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

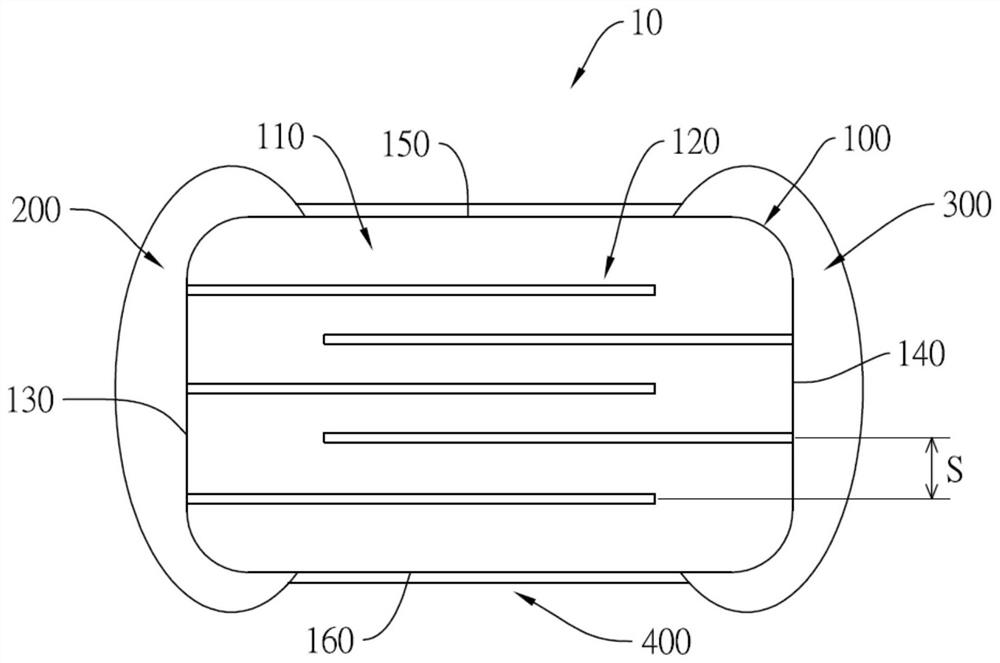

[0053] Preparation Example 1: Multilayer Ceramic Electronic Components

[0054] Each group of formulas shown in Table 1 is used as the starting raw material, and toluene and alcohol are used as the solvent. The amount of solvent added can be adjusted according to the required degree of dispersion, and the addition is about 0.5% by weight to 0.75% by weight of the total weight of the starting material. Percent polymeric dispersant (commodity model BYK-110, 111 and / or 115), and polyvinyl butyral resin binder added from about 25% by weight to 30% by weight of the total weight of the starting materials , and put it into a ball mill together with zirconium balls, and mix thoroughly with wet grinding to obtain ceramic slurry. The ceramic slurry is then formed into a sheet using a doctor blade method and then dried at a drying temperature of about 50 to 60° C.; the drying time is adjusted according to the actual situation to obtain a roll of thin tape.

[0055] Table 1: Ceramic comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com