Method for preparing MgB2 coating on stainless steel base

A stainless steel and coating technology, applied in the field of preparing MgB2 coating, can solve problems such as affecting superconducting properties, and achieve the effects of low cost, high electrical conductivity and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1 Preparation of MgB by sintering method 2 powder:

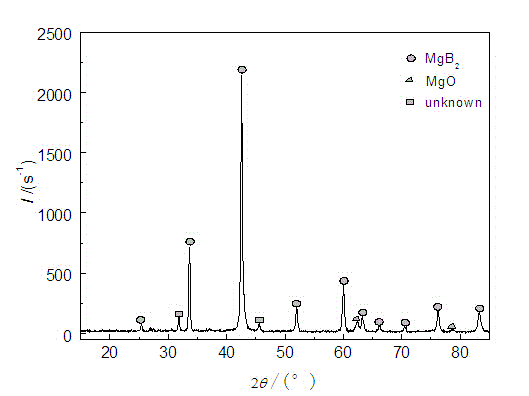

[0039] Use pure boron powder and pure magnesium powder as raw materials, control the atomic ratio of Mg and B in the raw materials to 1: 2, mix them evenly in an agate mortar, press them into thin slices with a diameter of 3cm at 8MPa, and sinter at a constant temperature of 500°C 3h, Ar-4%H was introduced during the sintering process 2 Gas provides a reducing atmosphere, and the sintered product is cooled and ground into powder to obtain MgB 2 powder, its XRD pattern is as figure 1 as shown,

[0040] From figure 1 It can be seen in powdered MgB 2 High purity, containing only a very small amount of magnesium oxide and unknown impurities;

[0041] Step 2 Pretreatment of stainless steel substrate:

[0042]Clean the stainless steel substrate ultrasonically for 40 minutes with a cleaning agent, finally wash it with deionized water, and dry it for later use;

[0043] Step 3. Deposition of MgB in methanol-iodin...

Embodiment 2

[0051] Step 1 Preparation of MgB by sintering method 2 powder:

[0052] Use pure boron powder and pure magnesium powder as raw materials, control the atomic ratio of Mg and B in the raw materials to 1: 2, mix them evenly in an agate mortar, press them into thin slices with a diameter of 2.5cm at 12MPa, and keep the temperature at 800°C Sintering for 2 hours, Ar-4%H was introduced during the sintering process 2 Gas provides a reducing atmosphere, and the sintered product is cooled and ground into powder to obtain MgB 2 powder;

[0053] Step 2 Pretreatment of stainless steel substrate:

[0054] Clean the stainless steel substrate ultrasonically for 10 minutes with a cleaning agent, finally wash it with deionized water, and dry it for later use;

[0055] Step 3. Deposition of MgB in methanol-iodine electrophoresis system 2 coating:

[0056] 3.1 Preparation of electrophoretic suspension:

[0057] Add 0.15g MgB in 50mL methanol 2 powder, 0.001g iodine pellets to make methan...

Embodiment 3

[0063] Step 1 Preparation of MgB by sintering method 2 powder:

[0064] Use pure boron powder and pure magnesium powder as raw materials, control the atomic ratio of Mg and B in the raw materials to 1: 2, mix them evenly in an agate mortar, press them into thin slices with a diameter of 2cm at 10MPa, and sinter at a constant temperature of 600°C 1.5h, Ar-4%H was introduced during the sintering process 2 Gas provides a reducing atmosphere, and the sintered product is cooled and ground into powder to obtain MgB 2 powder;

[0065] Step 2 Pretreatment of stainless steel substrate:

[0066] Clean the stainless steel substrate ultrasonically for 20 minutes with a cleaning agent, finally wash it with deionized water, and dry it for later use;

[0067] Step 3. Deposition of MgB in methanol-iodine electrophoresis system 2 coating:

[0068] 3.1 Preparation of electrophoretic suspension:

[0069] Add 0.2g MgB in 60mL methanol 2 Powder, 0.025g iodine grains are made into methanol-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com