A kind of positive temperature coefficient thermistor material and preparation method thereof

A positive temperature coefficient and thermistor technology, which is applied in the manufacture of resistors with positive temperature coefficients, thermistors, and resistors. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention simultaneously provides a preparation method for the above-mentioned positive temperature coefficient thermistor material, the steps comprising:

[0023] S1, by mass ratio BaTiO 3 :B 2 o 3 :SiO2 2 : Li 2 O:P 2 o 5 :Cs 2 O:Nd 2 o 3 =94.85%~97.75%: 0.4%~2.5%: 0.5%~0.9%: 0.08%~0.2%: 0.2%~0.3%: 0.6%~0.725%: 0.325%~0.565% mix barium titanate and oxide , ball milling, wherein, the mixing order and manner of each material are not limited in the present invention, and various ball milling techniques known to those skilled in the art can be used in the ball milling present invention, for example, a planetary ball mill can be used.

[0024]S2, including performing the first sintering on the powder material obtained in step S1 at 800-900°C, preferably the first sintering time is 100-120min, and the heating rate to the first sintering temperature is 4.2-5.2°C / min,

[0025] Preferably, the first sintering can adopt non-one-stage sintering, that is, pr...

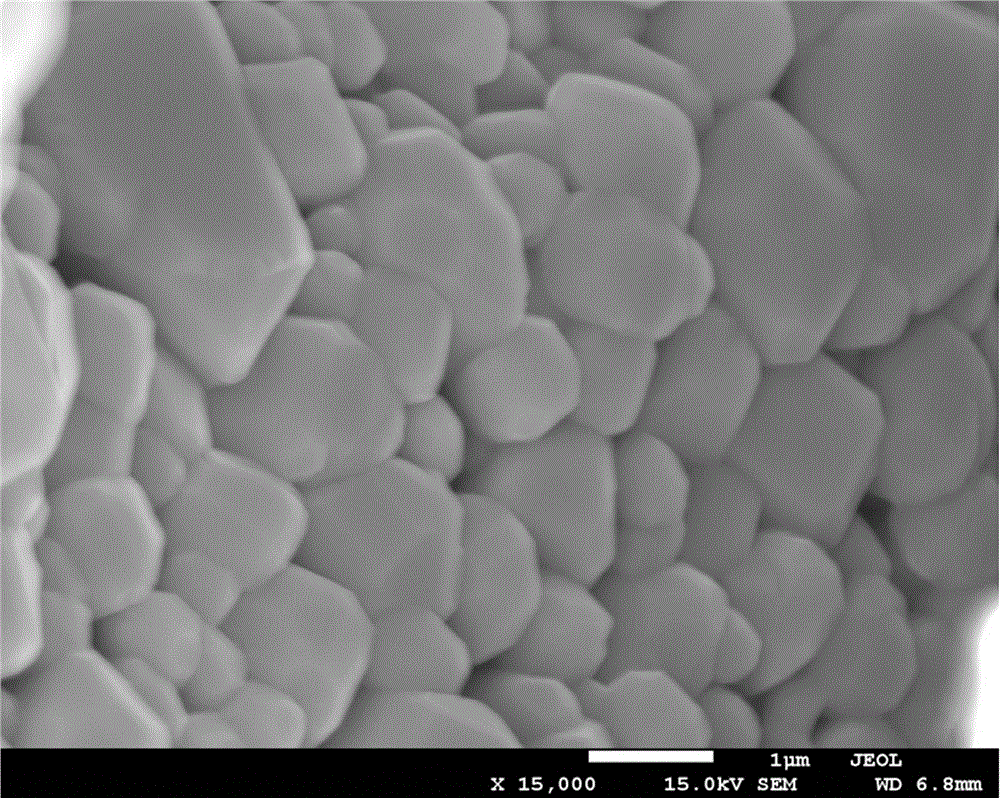

Embodiment 1

[0041] 1. BaTiO 3 Powder preparation:

[0042] (a) Prepare analytically pure barium chloride and oxalic acid into 0.5mol / L and 1.0mol / L solutions with deionized water respectively, mix well and let stand.

[0043] (b) Take 1000ml of oxalic acid solution and place it in an electronic constant temperature water bath at 60°C, then add barium chloride solution and analytically pure butyl titanate into the oxalic acid solution at 50ml / min, and turn on the magnetic stirrer for stirring, wherein the raw materials The ratio is barium chloride: butyl titanate: oxalic acid = 1:1:2, and the pH value of the solution is always controlled between 2.5 and 3.5 with ammonia water.

[0044] (C) Control the co-precipitation reaction time to be about 1 hour. After the reaction is over, turn off the magnetic stirrer and the constant temperature water bath, and leave the precipitate to stand for aging to obtain the titanium barium oxalate precursor. Then wash and filter to remove chloride ions an...

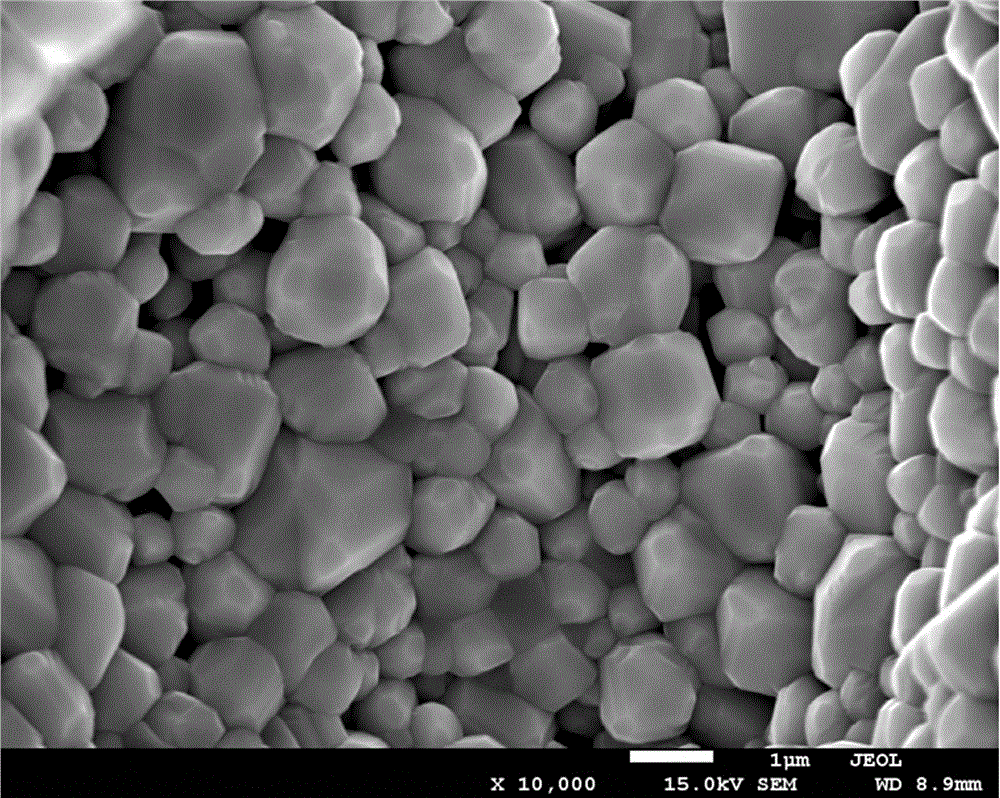

Embodiment 2

[0059] The PTC material sample S2 was prepared by the same method as in Example 1, except that (i) sintering in step 2: put the molded pellets obtained above into a high-temperature sintering furnace for sintering, and the heating rate was 5°C / min. Heat at 600°C for 100 minutes, remove the organic binder, hold at 1150°C for 40 minutes, perform supplementary synthesis, raise the temperature to 1225°C at 8°C / min, hold for 70 minutes, cool down at a rate of 2.3°C / h, cool down to 1100°C, and hold for 50 minutes , fully oxidized, cooled down to 200°C again, and cooled naturally to room temperature.

[0060] Using FESEM / EDS-field emission scanning electron microscope and accessory energy spectrometer to carry out scanning electron microscope analysis on the prepared PTC material sample S2, the electron microscope picture is as follows figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com