Optical fiber holographic interference measuring device

A technology of holographic interferometry and measurement device, which is applied in the direction of phase influence characteristic measurement, etc. It can solve the problems of complex scanning control mechanism, laborious and laborious, and slow measurement speed, and achieve the effects of simple overall structure design, cost reduction, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

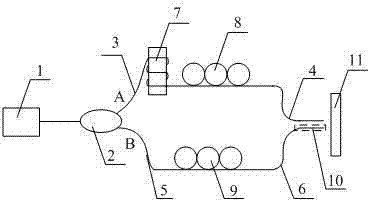

[0023] see figure 1 , a fiber holographic interferometry device, including a tunable laser light source (1), a single-mode fiber coupler (2), a piezoelectric ceramic cylinder (7), a first polarization controller (8), a second Two polarization controllers (9) and an image acquisition module (11), the tunable laser light source (1) is connected to the input end of the single-mode fiber coupler (2), and the two ends of the single-mode fiber coupler (2) The two output terminals (A, B) are respectively connected to the piezoelectric ceramic cylinder (7), the first polarization controller (8) and the second optical fiber (4) through the first optical fiber (3) to form a holographic interference reference arm, and the third optical fiber (5) Connect the second polarization controller (9), the fourth optical fiber (6) and the special optical fiber (10) in sequence to form a holographic interference signal arm, and the output light waves of the second optical fiber (4) and the special ...

Embodiment 2

[0028] This embodiment is the same as Embodiment 1, and the special features are as follows:

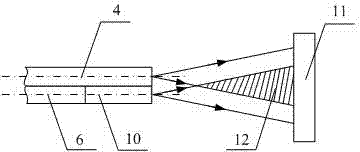

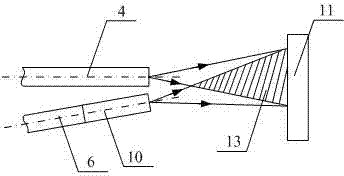

[0029] see figure 2 with image 3 ,

[0030] The interference fringe phase difference and visibility of the on-axis holographic interference area (12) and the off-axis holographic interference area (13) are determined by the deformation of the piezoelectric ceramic cylinder (7) and the first polarization controller (8) or controlled by the second polarization controller (9).

[0031] The range of the off-axis holographic interference area (13) is controlled by the angle between the second optical fiber (4) and the special optical fiber (10).

[0032] The operation method of this test device is as follows:

[0033] see figure 1 , figure 2 with image 3 .

[0034] The light emitted by the tunable laser light source (1) is divided into two beams through a single-mode fiber coupler (2), one beam of reference light and one beam of signal light, and its output wavelength is 1550 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com