Ternary compound wettable powder and preparation method and application thereof

A technology of wettable powder and wetting agent, which is applied in the field of wettable powder and its preparation, can solve the problems of unsatisfactory technical content and efficacy of manganese zinc in epidemic frost, low suspension rate of epidemic frost, etc., and achieve significant social and economic benefits , remarkable control effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

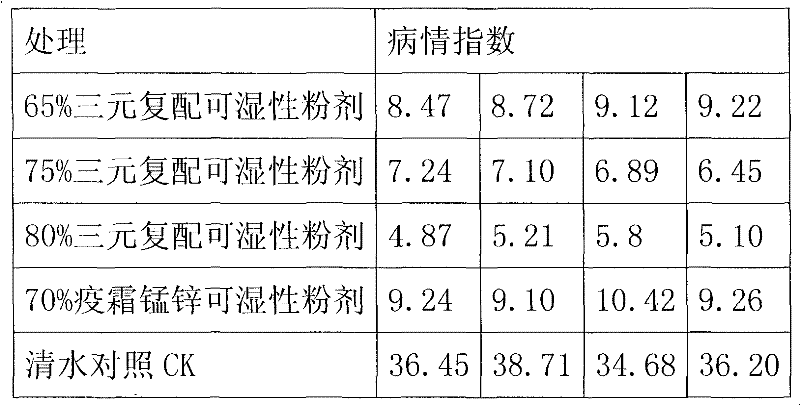

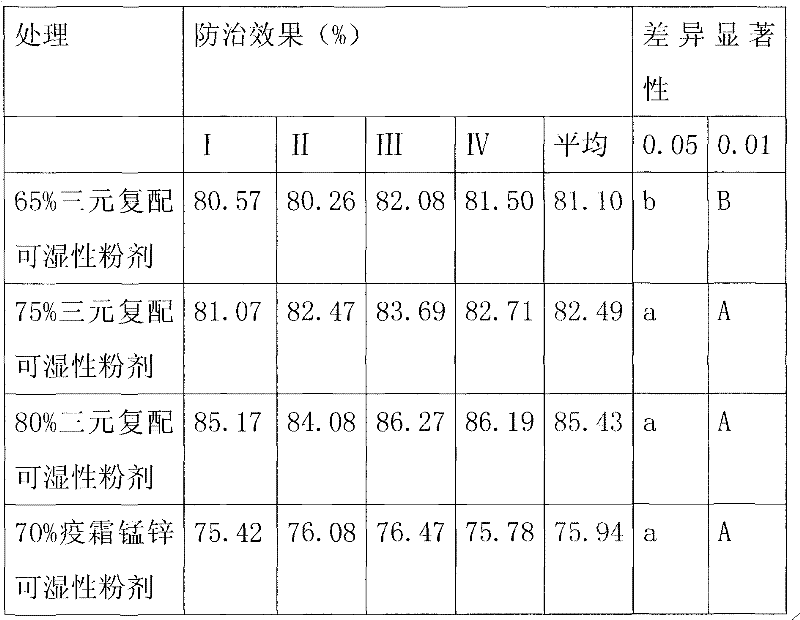

Examples

Embodiment 1

[0017] Embodiment 1: ternary composite wettable powder of the present invention, raw material consists of mancozeb: 50% (weight), fosfo-aluminum: 10% (weight), metalaxyl: 5% (weight), lignin Calcium sulfonate: 6% (weight), D-425: 4% (weight), sodium lauryl sulfate: 1% (weight), sodium citrate: 5% (weight) and calcined kaolin: 19% ( weight). The preparation method of this ternary compound wettable powder is that the above raw materials are fully mixed, and then enter the fluidized bed for airflow pulverization, so that the fineness reaches 10um, thereby obtaining 65% (mancozeb 50% + B Phosphorus aluminum 10% + metalaxyl 5%) ternary compound wettable powder, the 65% ternary compound wettable powder mancozeb suspension rate: 90%, ethyl phosphorus aluminum suspension rate: 92%, Suspension rate of metalaxyl: 92%; fineness 99% through 22um sieve; wettability ≤ 100 seconds.

Embodiment 2

[0018] Embodiment 2: ternary composite wettable powder of the present invention, raw material consists of mancozeb: 50% (weight), fosfo-aluminum: 20% (weight), metalaxyl: 5% (weight), lignin Calcium sulfonate: 7% (weight), D-425: 5% (weight), sodium lauryl sulfate: 1.5% (weight), sodium citrate: 4% (weight) and diatomaceous earth: 7.5% ( weight). The preparation method of the ternary compound wettable powder is the same as in Example 1, and a 75% (mancozeb 50%+fosmoluminum 20%+metalaxyl 5%) ternary compound wettable powder can be obtained. After testing, the 65% ternary compound wettable powder mancozeb suspension rate: 86%, ethyl fosmo aluminum suspension rate: 90%, metalaxyl suspension rate: 95%; fineness 99% passed through 22um sieve; wettability ≤80 seconds.

Embodiment 3

[0019] Embodiment 3: ternary composite wettable powder of the present invention, raw material is by mancozeb: 50% (weight), fosfo-aluminum: 20% (weight), metalaxyl: 10% (weight), lignin Calcium sulfonate: 8% by weight, D-425: 5% by weight, sodium lauryl sulfate: 2% by weight and sodium citrate: 5% by weight. The above raw materials are batched and stirred fully and evenly, and then entered into a fluidized bed for airflow pulverization to make the fineness reach 10um, thereby making 80% of the invention (mancozeb 50%+fosmozeb 20%+metalaxyl 10 %) ternary compound wettable powder. The suspension rate of mancozeb: 90%, fosfo-aluminum suspension rate: 93%, metalaxyl suspension rate: 98%; fineness (99% pass through 22um sieve); wettability ≤ 60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com