Method for preparing compound Chinese medicine microcapsules

A compound traditional Chinese medicine and microcapsule technology, applied in the field of medicine, can solve the problems of bad smell, low bioavailability and strong hygroscopicity of traditional Chinese medicine, and achieve the effects of easy mass production, wide source of raw materials and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

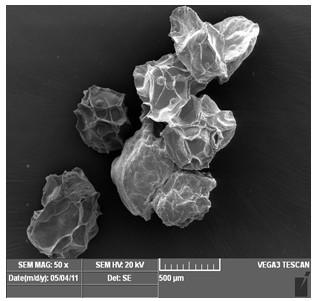

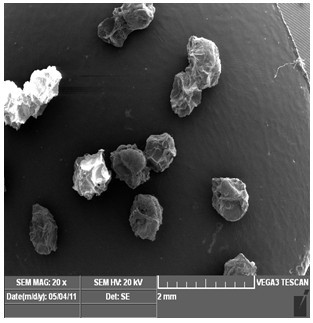

Image

Examples

Embodiment 1

[0025] (1) Prepare a 1wt% sodium alginate solution with distilled water at 60°C and stir at 2000rpm for 30 minutes to obtain a uniform and transparent solution.

[0026] (2) Capsule core: Compound Yishen Mixture, for chronic renal failure, weighed a certain quality of rhubarb, astragalus, salvia, rehmannia, poria, boiled with distilled water to extract Chinese medicine.

[0027] (3) Add the compound Chinese medicine extract to the sodium alginate solution, the volume ratio of the two is 1:4, and magnetically stir to make it evenly mixed.

[0028] (4) Prepare a calcium chloride solution with a mass concentration of 8% and adjust the pH to 5.87 with acid.

[0029] (5) Connect the positive electrode of the high-voltage generator to the syringe needle, and the negative electrode to the bottom of the measuring cup containing the calcium chloride solution, and adjust the voltage to 8000V.

[0030] (6) Place the sodium alginate-compound traditional Chinese medicine mixture in the needle of the...

Embodiment 2

[0034] (1) Prepare a 1wt% sodium alginate solution with distilled water at 60°C and stir at 2000rpm for 30 minutes to obtain a uniform and transparent solution.

[0035] (2) Capsule core: liquid flavor.

[0036] (3) Add flavor to the sodium alginate solution, the volume ratio of the two is 1:1, add surfactant PVP according to the addition ratio of 0.5%-2.5% (W / V), and magnetically stir for 40 minutes to make it evenly mixed.

[0037] (4) Prepare a calcium chloride solution with a mass concentration of 5% and adjust the pH to 5.87 with acid.

[0038] (5) Connect the positive pole of the high-voltage generator to the syringe needle, and the negative pole to the bottom of the measuring cup containing the calcium chloride solution, and adjust the voltage to 6000V.

[0039] (6) Place the sodium alginate-flavor mixture in the needle of the syringe, push the piston handle of the syringe by the micro-syringe pump, and drop the sodium alginate-flavor mixture into the chlorination with a mass con...

Embodiment 3

[0043] (1) Prepare a 1wt% sodium alginate solution with distilled water at 60°C and stir at 2000rpm for 30 minutes to obtain a uniform and transparent solution.

[0044] (2) Capsule core: liquid flavor.

[0045] (3) Add flavor to the sodium alginate solution, the volume ratio of the two is 1:1, add surfactant PVP according to the addition ratio of 0.5%-2.5% (W / V), and magnetically stir for 40 minutes to make it evenly mixed.

[0046] (4) Prepare a calcium chloride solution with a mass concentration of 5%, and adjust the pH to 7.5 with alkali.

[0047] (5) Connect the positive electrode of the high-voltage generator to the syringe needle, and the negative electrode to the bottom of the measuring cup containing the calcium chloride solution, and adjust the voltage to 4000V.

[0048] (6) Place the sodium alginate-flavor mixture in the needle of the syringe, push the piston handle of the syringe by the micro-syringe pump, and drop the sodium alginate-flavor mixture into a chlorinated soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com