Method for recovering energy of incompletely regenerated flue gas generated in process of preparing olefin from methanol

A methanol-to-olefin, complete regeneration technology, applied in separation methods, air quality improvement, chemical instruments and methods, etc., can solve the problems of low temperature and pressure, high content, low energy recovery efficiency of hoods, etc., to eliminate CO pollution , good technical effect, the effect of eliminating the scaling of the adherent catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

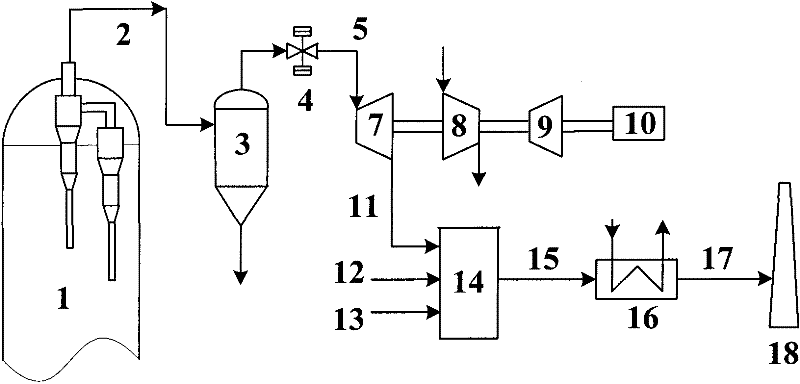

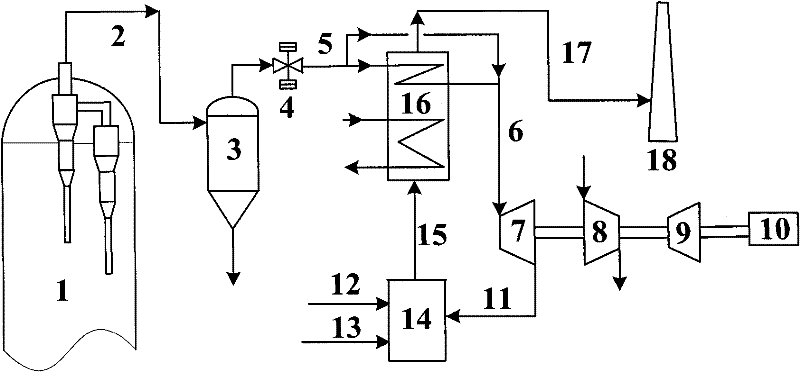

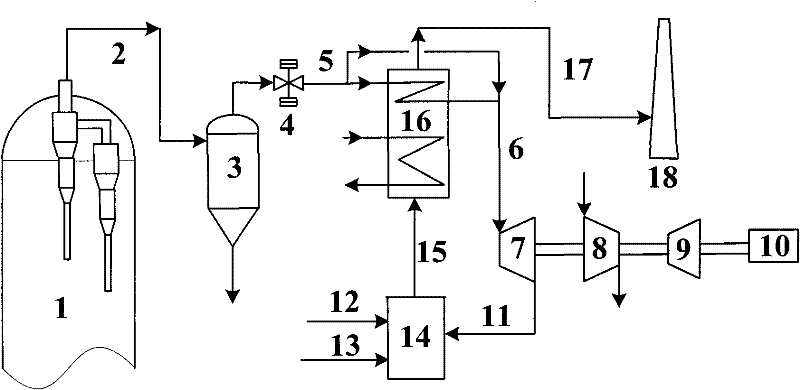

[0026] The MTO device adopts an incomplete regeneration process with oxygen-poor main air, the temperature of the regeneration flue gas is 560°C, the pressure is 0.26MPa, and the molar composition of the flue gas is: CO 11.5%, O 2 1.2%, CO 2 4.9%, N 2 74.1%, H 2 O is 8.3%, and the flue gas volume is 215NM 3 / MIN. The energy recovery process of incompletely regenerated flue gas is as follows: figure 2 As shown, after passing through the third-stage cyclone separator and slide valve, the temperature of the regenerated flue gas is 500°C, the pressure is 0.24MPa, and then 70% of the flue gas is sent to the waste heat boiler to be heated to 650°C to start combustion, and then enters the flue gas In the flue before the gas turbine, the O contained in the flue gas is used 2 Combustion is carried out, and then mixed with 30% flue gas that has not been heated by the waste heat boiler to complete the first stage of combustion. The temperature of the flue gas combustion rises to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com