Method for chemically synthesizing nano lead-free solder particles with low melting point

A technology of lead-free solder alloy and lead-free solder, which is applied in the field of chemical synthesis of low-melting point nano-lead-free solder particles, can solve the problems of no similar patents, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

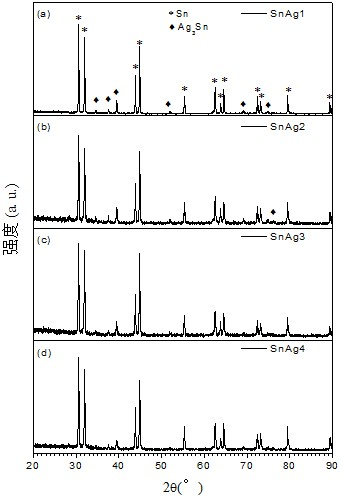

[0038] This embodiment selects the lead-free solder alloy of Sn3.5Ag, and the specific process steps are as follows:

[0039] a. Weigh 0.2998g of stannous octoate, 0.0051g of silver nitrate (the weight ratio of Sn and Ag is 96.5 / 3.5) and 0.2775g of phenanthroline and add it to 50ml of absolute ethanol, and use a magnetic stirrer to stir in the atmosphere Stir vigorously for 2 hours under ambient conditions to obtain a uniformly mixed precursor solution;

[0040] b. Dissolve 0.1892g of sodium borohydride into 50ml of absolute ethanol solution, and form a uniform solution after vigorous stirring;

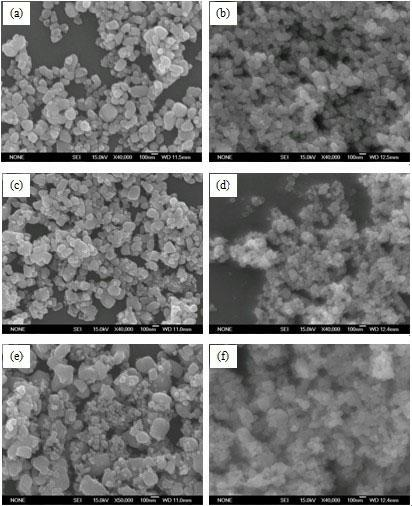

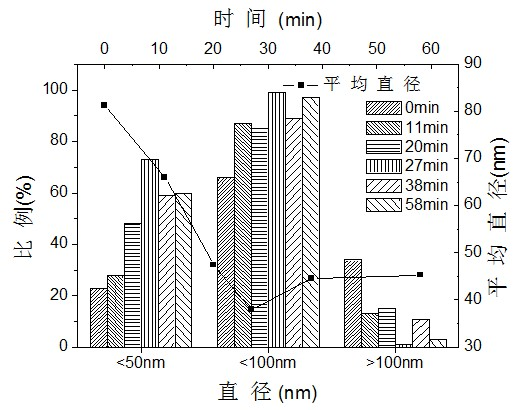

[0041] c. Prepare 6 parts of the precursor solution in step a, drop the reducing agent solution into 6 parts of the precursor solution, the titration time is 0 min, 11 min, 20 min, 27 min, 38 min and 58 min, and the rate of addition is controlled to Control the size and degree of agglomeration of nanoparticles;

[0042] d. Use a centrifuge to precipitate the Sn3.5Ag nanoparticles ob...

Embodiment 2

[0046] This embodiment selects the lead-free solder alloy of Sn3.0Ag0.5Cu. The specific process steps are basically the same as in Embodiment 1. The difference is that copper acetate is added to the reactant, and the weight ratio of Sn / Ag / Cu in the precursor solution for 96.5 / 3.0 / 0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com