High-pressure shearing deformation method and device for tubular materials

A high-pressure shearing and deformation device technology, applied in the direction of presses, manufacturing tools, mechanical equipment, etc., can solve the problems that the friction force cannot reach the yield strength of the material, affect the processing process, and the circumferential friction force is limited. Simple, strong processing capacity, high hydrostatic pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

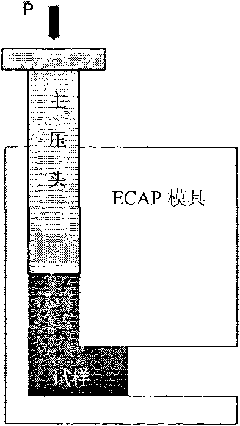

[0020] The material processing purpose of the present invention can be realized on the traditional extruder with constant pressure function: the tubular workpiece is placed on the lower anvil, the outer side of the workpiece is covered with a rotatable rigid ring, and the rigid mandrel passes through the center of the tubular workpiece. However, the upper anvil directly transmits the axial pressure to the workpiece, and the tubular workpiece tends to expand in the radial direction under the action of the huge axial pressure. The rigid disk and the mandrel play a role in restraining the radial deformation of the tubular workpiece. This design of applying high pressure to the end of the tubular workpiece while limiting its deformation results in the accumulation of high hydrostatic pressure (1GPa-15GPa) inside the workpiece. Under high hydrostatic pressure conditions, great friction will be generated on both the inner and outer walls of the tubular workpiece. Although the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com