Oxygen-deficiency pyrolyzing circular sludge incinerator

A technology of sludge incineration and annular combustion chamber, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of environmental pollution around the landfill, high sludge transportation costs, sludge air pollution, etc., and achieve economical operation The effect of cost, small footprint and low one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

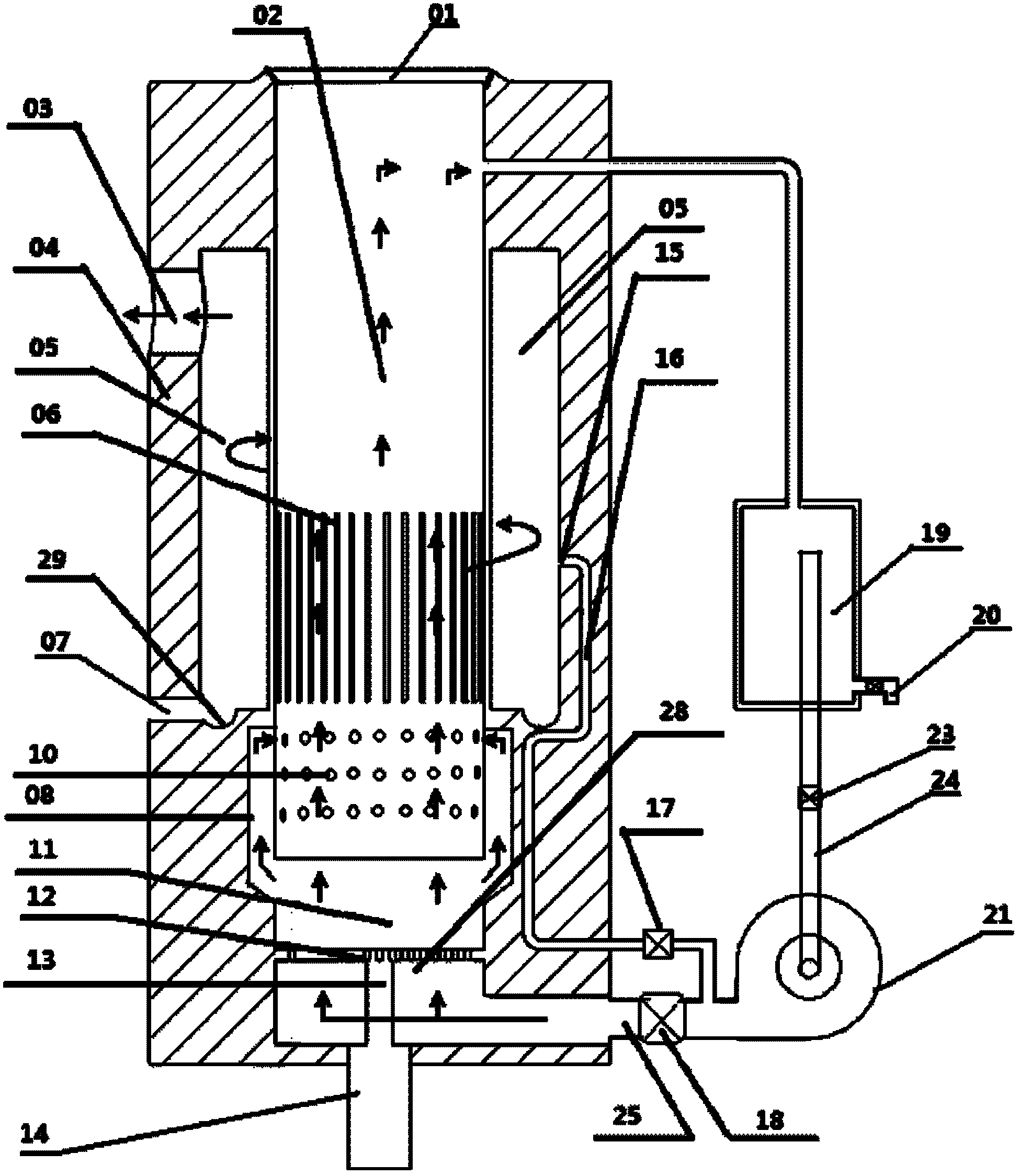

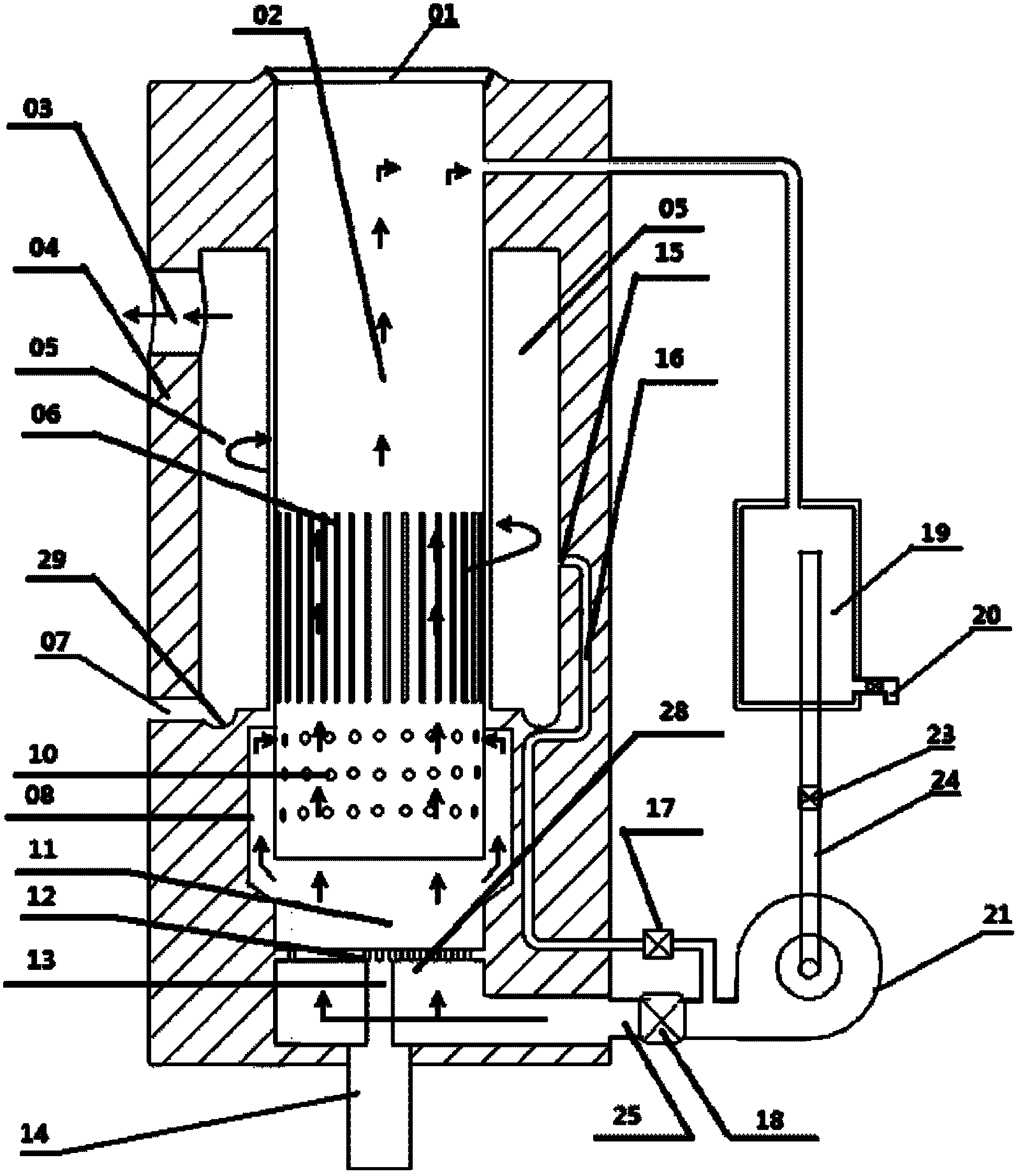

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] A kind of anaerobic pyrolysis annular sludge incinerator, comprising a furnace body 02, also includes a furnace bottom 28, a condenser 19 and a fan 21, the top of the furnace body is provided with a furnace cover 01, and the middle part of the furnace body is provided with Ventilation smoke outlet 06, the bottom of the furnace body is provided with a ventilation hole 10, the outer circumference of the middle and upper part of the furnace body is provided with an annular combustion chamber 05, and the upper part of the annular combustion chamber is provided with a smoke exhaust port 03, so The bottom of the annular combustion chamber is provided with an ash collection tank 29, the ash collection tank is provided with an ash removal port 07, and at least one air supply nozzle 15 is provided on the outer wall of the annular combustion chamber, and the fan passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com