Optical waveguide for optical connector, optical connector using same, and method of manufacturing optical waveguide for optical connector

An optical connector and waveguide technology, applied in the coupling, optical, optical and other directions of optical waveguides, can solve the problems of increasing optical coupling loss, large deviation of the width direction of the optical waveguide, inconsistent optical axes, etc., to prevent optical coupling loss. The effect of increasing the number of products, small variation between products, and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

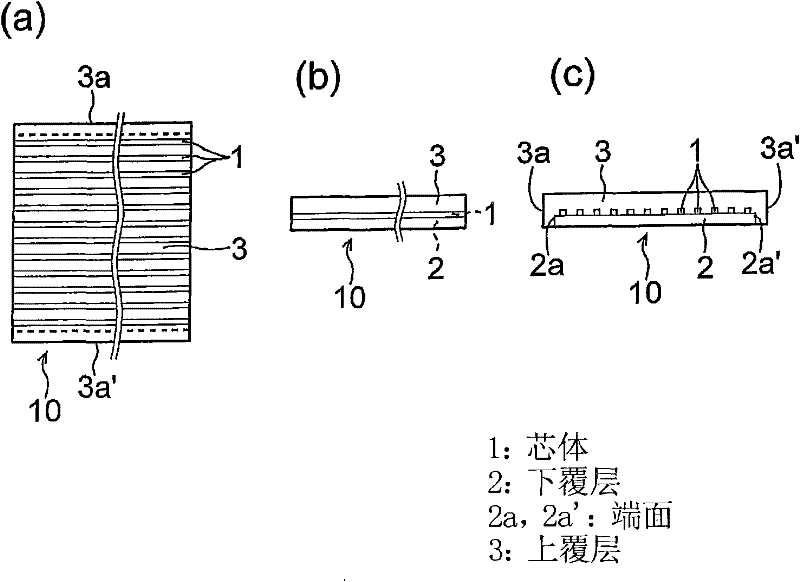

[0094] 〔Fabrication of Under Cladding〕

[0095] First of all, using a spin coater The spin coating method applied the material for forming the under-cladding layer used in Example 1 above to the glass substrate 2 365nm radiation To make an exposure. The quartz photomask M1 has openings of a square pattern (width 2.88 mm×length 102.0 mm) corresponding to the under cladding layer, and is separated from each other on a line parallel to the length (long side) direction of the square opening Two openings are formed in a pattern corresponding to the ring-shaped alignment mark A (diameter 1 mm, width 50 μm). Immediately afterwards, heat treatment was performed at 150°C for 10 minutes. Then, after using Y-butyrolactone After performing immersion development for 3 minutes to dissolve and remove the unexposed part, heat treatment is performed at 150° C. for 10 minutes to form an under cladding layer and two ring-shaped alignment marks A on the substrate. The cross-sectional size of th...

Embodiment 2

[0105] 〔Fabrication of Under Cladding〕

[0106] First of all, using a spin coater The spin coating method applied the material for forming the under-cladding layer used in Example 1 above to the glass substrate 2 365nm radiation For exposure, the quartz photomask M1 has an opening with a square pattern (width 2.90 mm × length 102.0 mm) corresponding to the under cladding layer, and is on a line parallel to the length (long side) direction of the square opening Openings in a pattern corresponding to the ring-shaped alignment mark A (diameter 1 mm, width 50 μm) are formed at two places separated from each other. Immediately afterwards, heat treatment was performed at 100°C for 15 minutes. Then, after using Y-butyrolactone After performing immersion development for 3 minutes to dissolve and remove the unexposed parts, heat treatment at 150° C. for 15 minutes was performed to form the under cladding layer and two ring-shaped alignment marks A on the substrate. The cross-sectional...

Embodiment 3

[0116] 〔Fabrication of Under Cladding〕

[0117] First of all, using a spin coater The spin coating method applied the material for forming the under-cladding layer used in Example 3 above to the glass substrate 2 365nm radiation For exposure, the quartz photomask M1 has an opening with a square pattern (width 2.885 mm×length 102.0 mm) corresponding to the under cladding layer, and is positioned on a line parallel to the length (long side) direction of the square opening Openings in a pattern corresponding to the ring-shaped alignment mark A (diameter 1 mm, width 50 μm) are formed at two places separated from each other. Next, heat treatment is performed at 70°C×15 minutes. Then, after using Y-butyrolactone After performing immersion development for 3 minutes to dissolve and remove the unexposed parts, heat treatment at 150° C. for 15 minutes was performed to form the under cladding layer and two ring-shaped alignment marks A on the substrate. The cross-sectional dimensions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com