Method for preparing structural-color contact lens

A contact lens and structural color technology, applied in glasses/goggles, applications, instruments, etc., can solve the problems of unsatisfactory safety, sanitation, beautiful appearance, lack of preparation method of structural color contact lenses, etc., achieve bright colors, easy to use Large-scale production and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

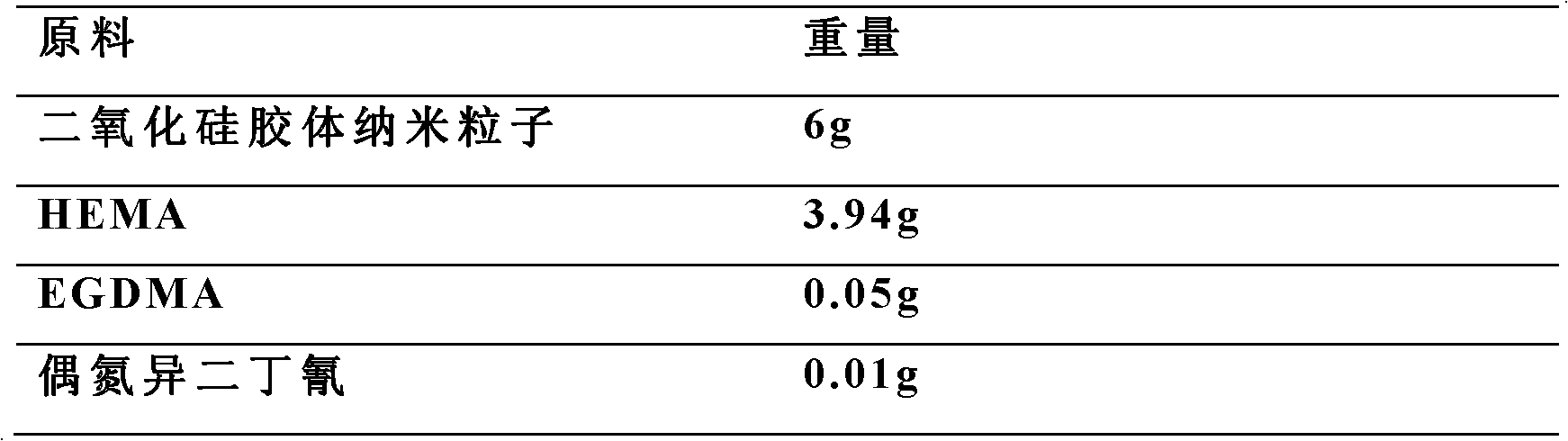

[0032] Example 1 Preparation of Structural Color Contact Lenses

[0033]

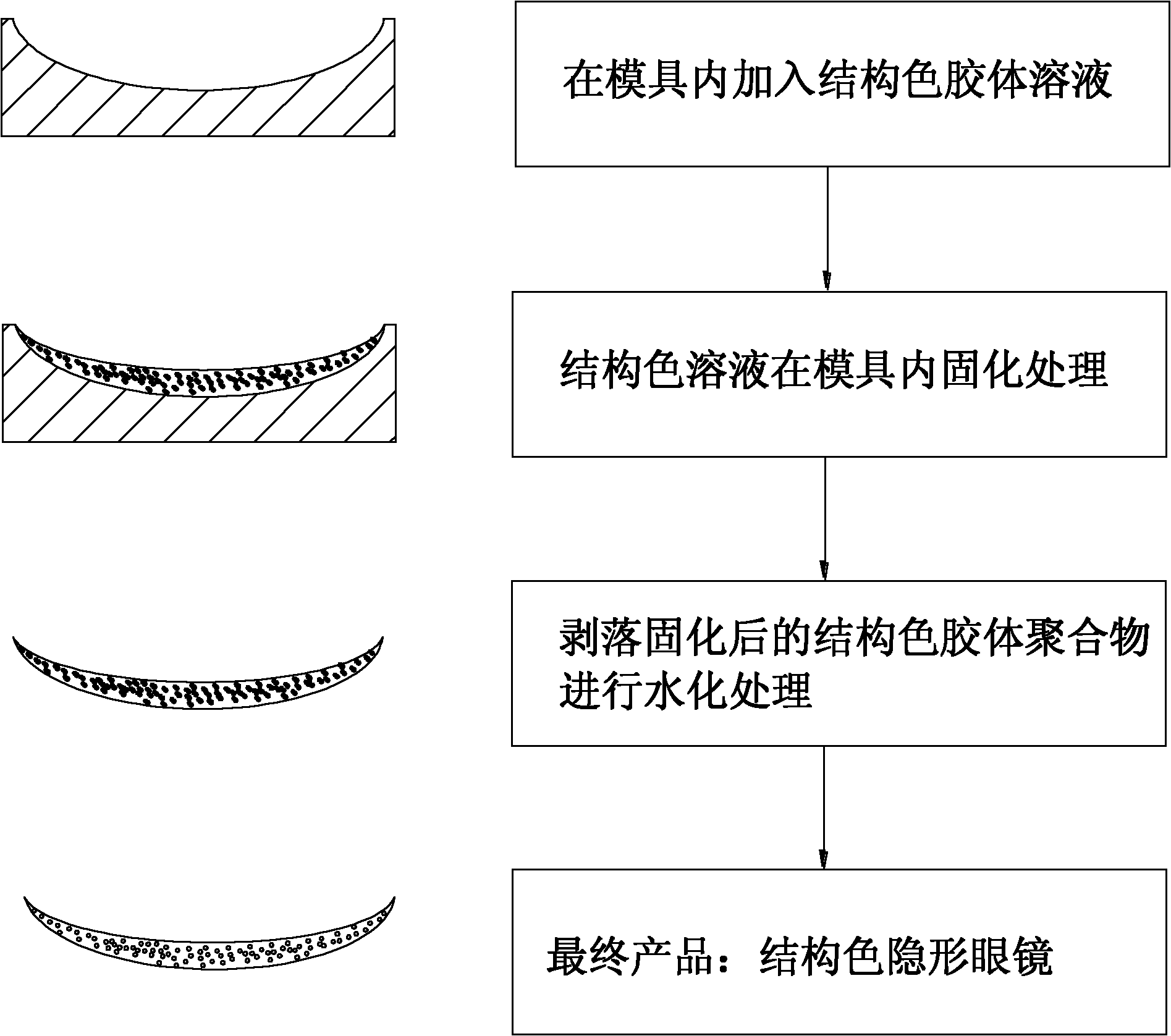

[0034] Such as figure 1 The steps shown are to prepare structural color contact lenses, and the following is a specific description:

[0035] 1. Preparation of structural color colloid solution:

[0036] Monodisperse silica colloidal nanoparticles with a diameter of 200 nm were added to a mixed solution of hydroxyethyl methacrylate (HEMA) and ethylene glycol dimethacrylate (EGDMA) (HEMA / EGDMA=20:1, mole ratio), adjust the mass percent of silicon dioxide to be 60%, and ultrasonically disperse until the colloidal particle solution produces a bright and bright structural color; in this solution, add initiator azoisodibutylcyanide (0.1%, mass volume ratio) , after fully mixing, pass nitrogen gas for 5 minutes, and seal the structural color colloid solution for later use;

[0037] 2. Curing treatment of structural color solution in the mold:

[0038] Add 200 microliters of structural chromatic colloid...

Embodiment 2

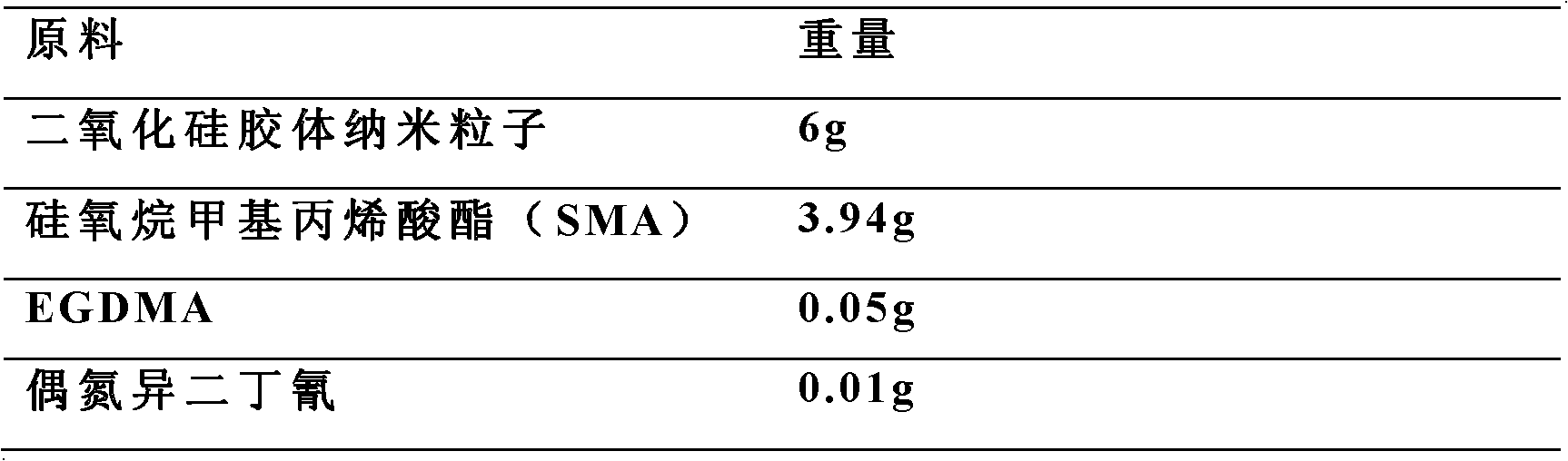

[0041] Example 2 Preparation of Structural Color Contact Lenses

[0042]

[0043] 1. Preparation of structural color colloid solution:

[0044] Add the monodispersed silica colloidal nanoparticles with a diameter of 200 nanometers into a mixed solution of siloxane methacrylate (SMA) and ethylene glycol dimethacrylate (EGDMA), and adjust the mass percentage of silica to 40%, ultrasonic dispersion, until the colloidal particle solution produces a bright and bright structural color; add the initiator azoisodibutylcyanide (0.1%, mass volume ratio) to this solution, after fully mixing, pass through nitrogen for 5min, seal Structural color colloid solution for standby;

[0045] 2. Curing treatment of structural color solution in the mold:

[0046] Add 200 microliters of structural color colloid solution into the mold used for contact lens preparation, let it stand for 20 minutes, react in a water bath at 40°C for 22 hours, heat up to a vacuum drying oven at 120°C for 9 hours, a...

Embodiment 3

[0049] Example 3 Preparation of Structural Color Contact Lenses

[0050]

[0051] 1. Preparation of structural color colloid solution:

[0052] Add monodisperse polymethyl methacrylate colloidal nanoparticles with a diameter of 180 nm into a mixed solution of hydroxyethyl methacrylate (HEMA) and ethylene glycol dimethacrylate (EGDMA) (HEMA / EGDMA=20: 1, mol ratio), the mass percent of regulating polymethyl methacrylate is 50%, ultrasonic dispersion, until the colloidal particle solution produces bright and bright structural color; In this solution, add initiator azoisodibutylcyanide (0.1 %, mass-to-volume ratio), after fully mixing, pass through nitrogen gas for 5 minutes, and seal the structural color colloid solution for subsequent use;

[0053] 2. Curing treatment of structural color solution in the mold:

[0054] Add 200 microliters of structural chromatic colloid solution into the mold used for contact lens preparation, let it stand for 20 minutes, and irradiate it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com