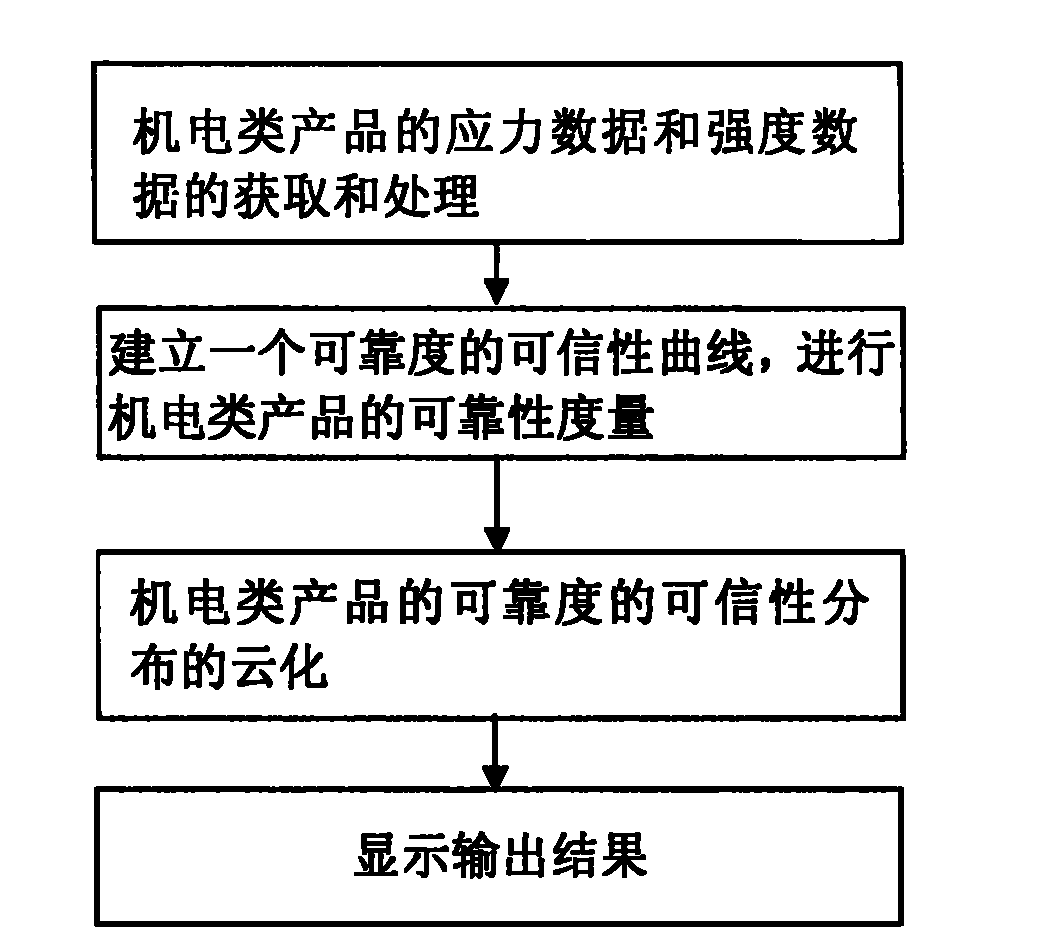

Method for measuring reliability of electromechanical product

A measurement method and reliability technology, applied in measuring devices, electrical digital data processing, special data processing applications, etc., can solve problems such as ambiguity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

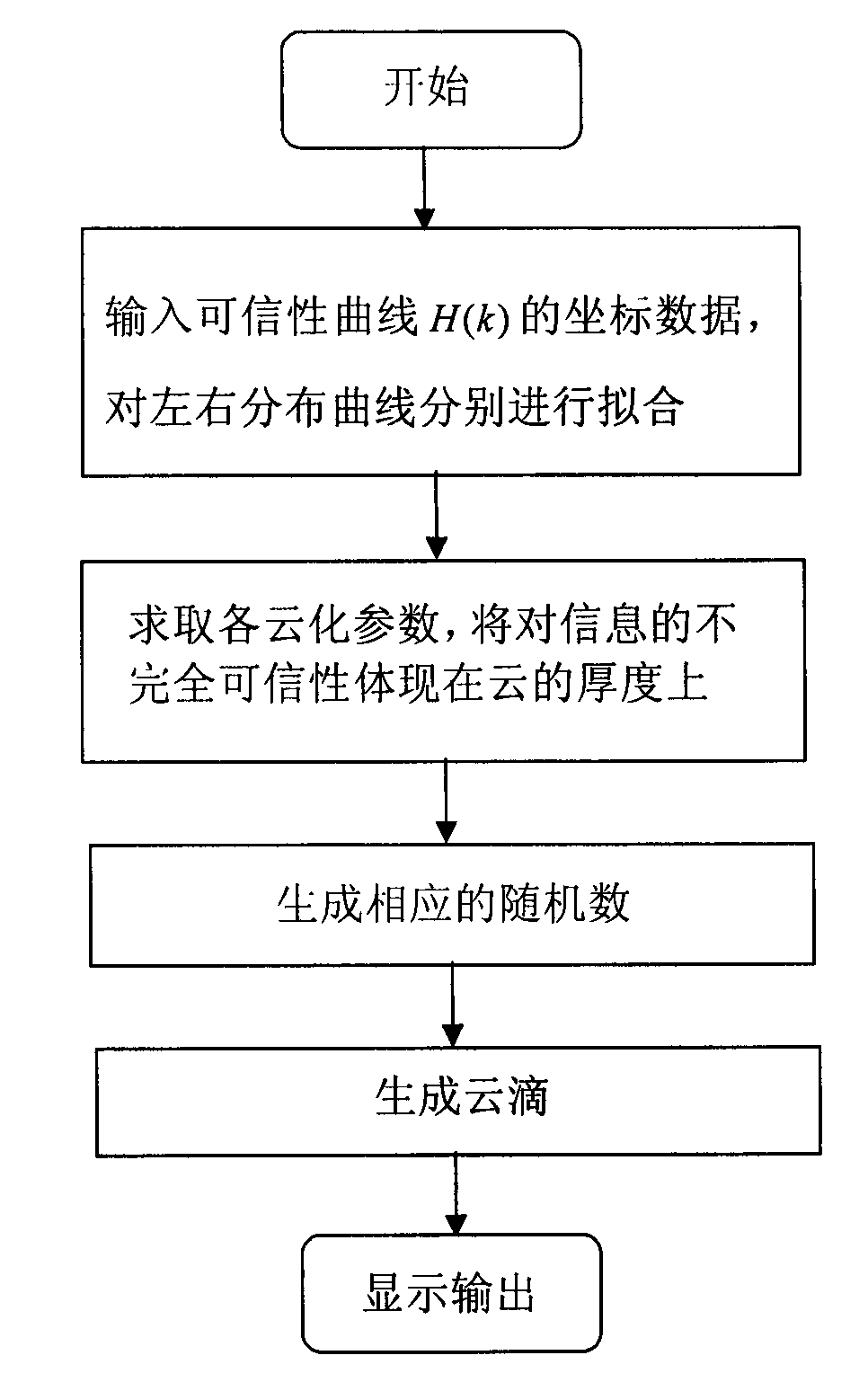

Method used

Image

Examples

Embodiment 1

[0061] A Reliability Measurement of Aluminum Electrolytic Capacitor

[0062] Step 1, acquisition of stress data and strength data of the aluminum electrolytic capacitor

[0063] When the aluminum electrolytic capacitor is working normally in a certain circuit, the voltage at both ends of the capacitor is detected on site, and 200 stress data are obtained; from the factory data provided by the manufacturer, the withstand voltage value of the aluminum electrolytic capacitor is 50V when it is working, which is the strength data.

[0064] Step 2, processing the stress data and strength data of the aluminum electrolytic capacitor

[0065] Input the stress data and strength data of the aluminum electrolytic capacitor obtained in step 1 into the single-chip microcomputer for the following processing;

[0066] (2.1) Processing of the stress data of the acquired aluminum electrolytic capacitor

[0067] The input stress data of the aluminum electrolytic capacitor is 200 ≥ 100, which ...

Embodiment 2

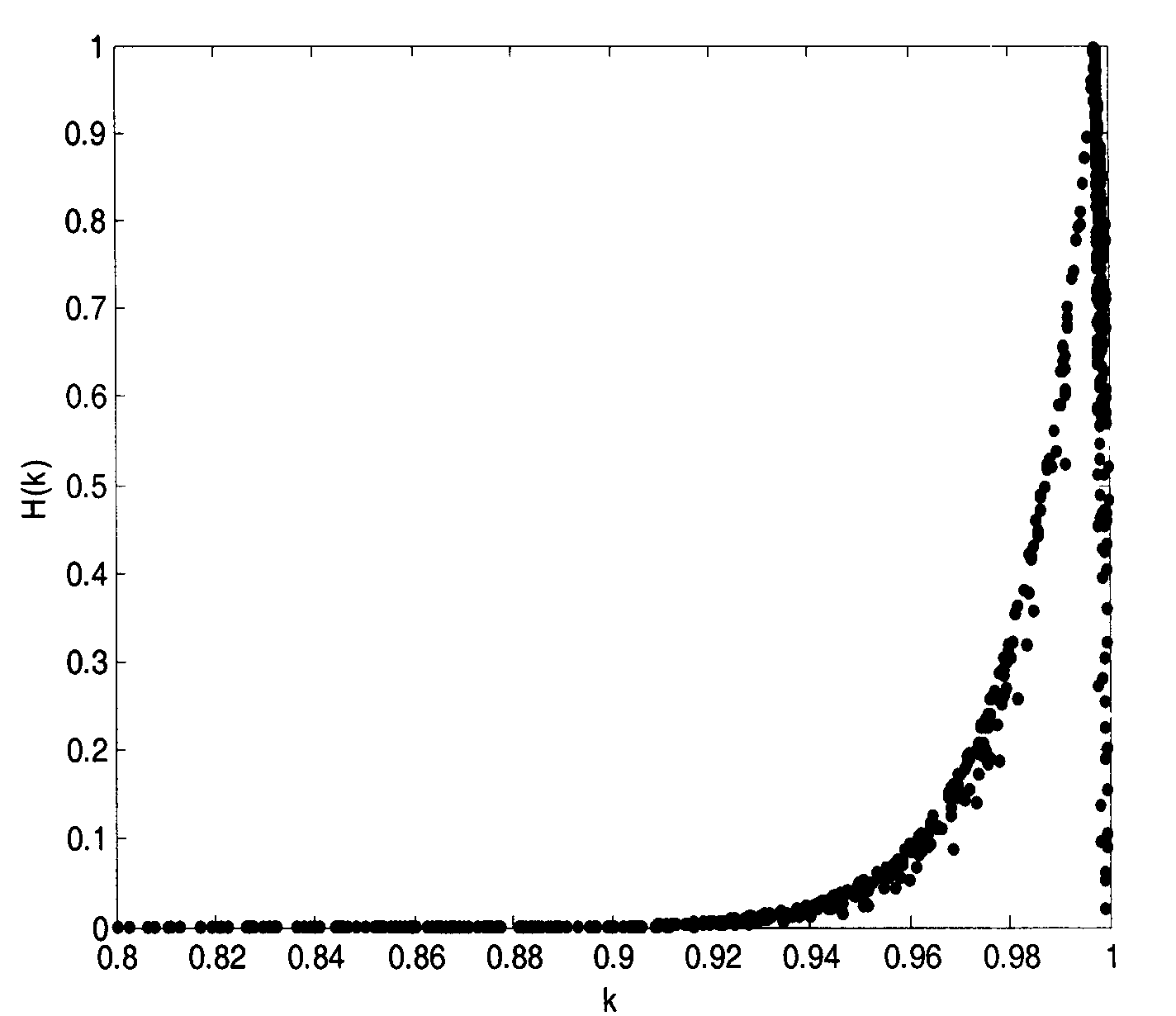

[0089] A Reliability Measurement of Mechanical Bearings

[0090] Step 1, acquisition of stress data and strength data of the mechanical bearing

[0091] Through the field data collection of the experiment, the mechanical bearing is subjected to pressure during work, and the obtained tensile stress data is 100; from the factory data provided by the manufacturer, the strength data is that the mechanical bearing can bear the pressure between 100Mpa and 108Mpa.

[0092] Step 2, processing of stress data and strength data of the mechanical bearing

[0093] Input the stress data and strength data of the mechanical bearing obtained in step 1 into the single-chip microcomputer for the following processing;

[0094] (2.1) Processing of the acquired stress data of the mechanical bearing

[0095] 100 pieces of stress data of the input mechanical bearing = 100, the stress data is regarded as random stress data s, the random probability density distribution function of its stress distrib...

Embodiment 3

[0119] A Reliability Measurement of Auto Parts

[0120] Step 1, acquisition of stress data and strength data of the auto parts

[0121] When the auto part is working in the car, it will bear a certain force. The force is detected on site, and 50 data are obtained as stress data. From the factory data provided by the manufacturer, the strength data of the auto part is 100Mpa.

[0122] Step 2, the processing of the stress data and strength data of the auto parts

[0123] The stress data and the strength data of the automobile parts that step 1 obtains are input into the single-chip microcomputer and are processed as follows;

[0124] (2.1) Processing of the acquired stress data of the auto parts

[0125] The stress data of the input auto parts is 50, and the stress data is regarded as fuzzy stress data Its fuzzy membership function is The fuzzy membership function established according to the input stress data is a normal fuzzy number

[0126] (2.2) Processing of the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com