Solar cell and method for making same

A technology of solar cells and anode electrodes, applied in electrical components, capacitor electrodes, capacitor parts and other directions, can solve the problem of ineffective utilization, and achieve the effects of improving photoelectric conversion efficiency, increasing photocurrent density, and suppressing dark reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in detail below, wherein the same or similar elements are denoted by the same or similar reference numerals throughout the drawings. These examples are exemplary, and are only used for explaining the present invention, and should not be construed as limiting the present invention.

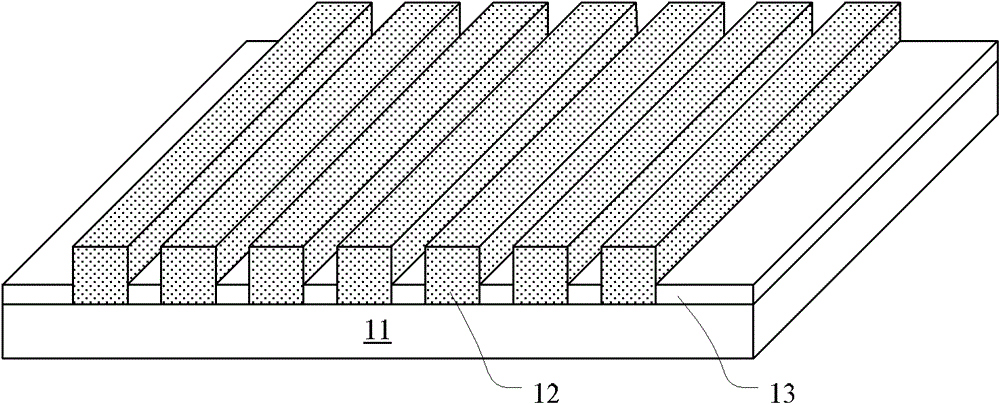

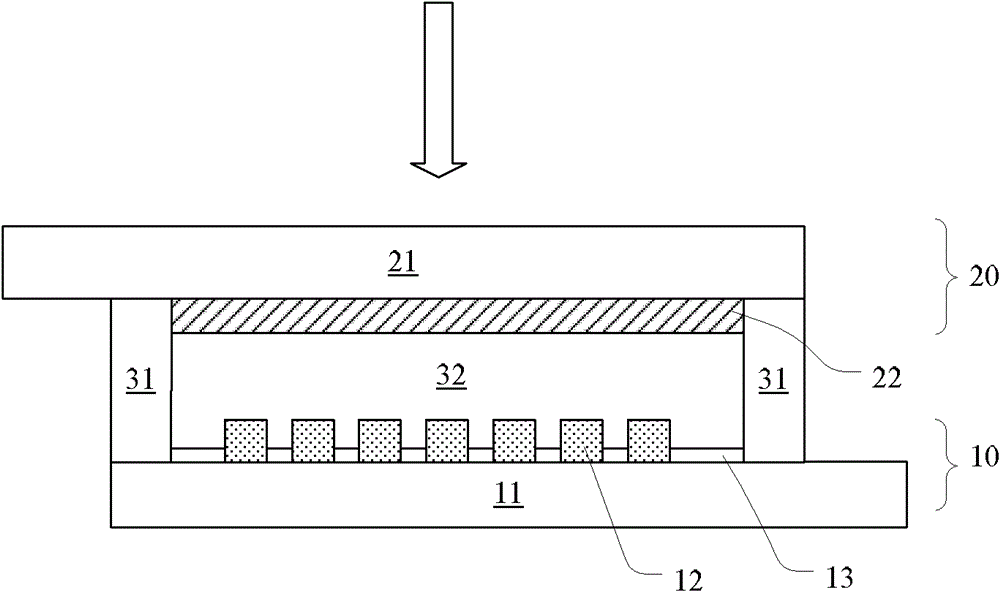

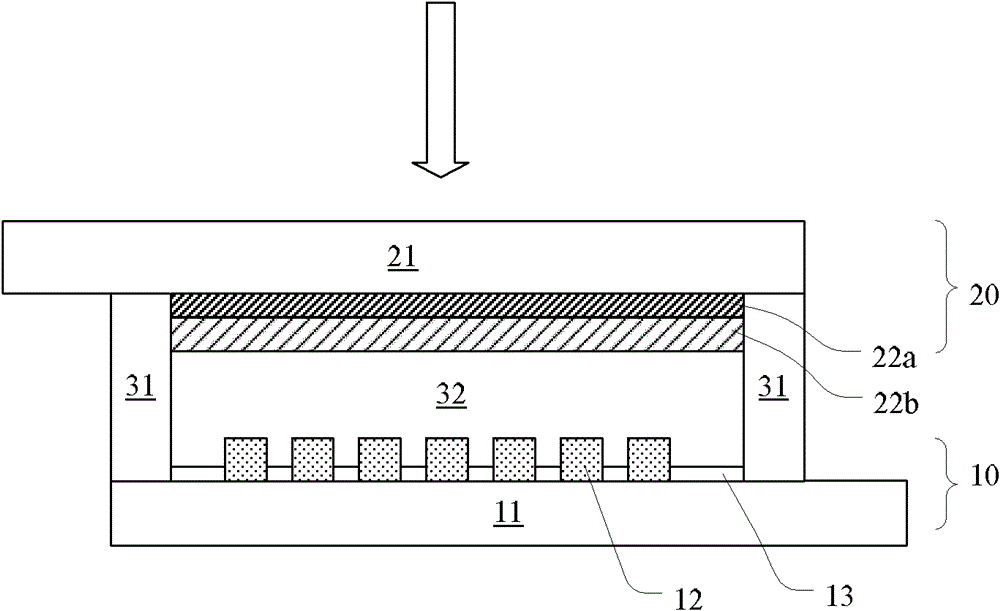

[0047] figure 1 It is a schematic structural view of the anode assembly in the DSSC according to the present invention. The anode assembly includes a transparent conductive substrate 11 , a CdTe layer 12 on the transparent conductive substrate 11 , and an anode electrode layer 13 (such as platinum) in the opening of the CdTe layer 12 . The CdTe layer 12 is a polycrystalline film with a thickness of 1-2.0 μm. Preferably, the thickness of the CdTe layer 12 is 1.5 μm. The particle size of CdTe in the CdTe layer 12 is 90-120nm. Preferably, the particle size of CdTe in the CdTe layer 12 is 100 nm. The thickness of the anode electrode lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com