Dust removal washing and purification device for industrial waste gas

A purification device and industrial waste gas technology, which is applied in the direction of combined devices, chemical instruments and methods, and dispersed particle filtration, etc. It can solve the problems of unsmooth airflow, difficult processing and manufacturing, and failure to meet dust removal standards in the dust removal system, achieving maintenance-free Effects that clean up, save manufacturing costs, and are less difficult to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

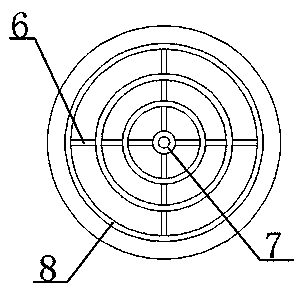

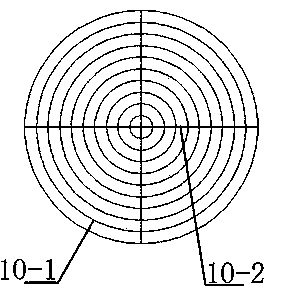

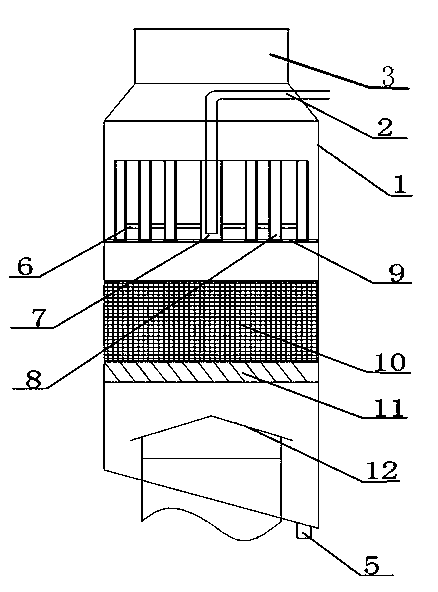

[0024] as attached figure 1 , 2 , 3, an embodiment of the present invention is an industrial waste gas dedusting, washing and purifying device, which includes a housing 1, and a water inlet pipe 2 and a sewage discharge pipe 5 provided as a set, the upper end of the housing 1 is a flue gas outlet 3, and the lower part of the housing 1 exhausts smoke A water blocking cap 12 is provided on the exhaust gas outlet of the equipment. The upper part of the shell 1 is provided with a water flow buffer and equal distribution structure, which includes a bracket 9 fixed on the shell 1, and a two-way water flow equalizer 8 and a water-bearing overflow bucket 7 arranged on the bracket 9; The two-way water flow equalizer 8 is composed of 10-20 concentric ring-shaped barrels connected to each other, and the water-bearing equal-split overflow barrel 7 is arranged in the center of the support 9, that is, the ring-shaped barrels of the two-way water flow equalizer 8 The central part of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com