Numerical control universal worm grinder

A worm grinding machine, a universal technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problem of not being able to grind cone enveloping toroidal worms, ordinary cylindrical worms, or toruses. Worm and other problems, to achieve the effect of ingenious design, good rigidity, and reasonable workpiece clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

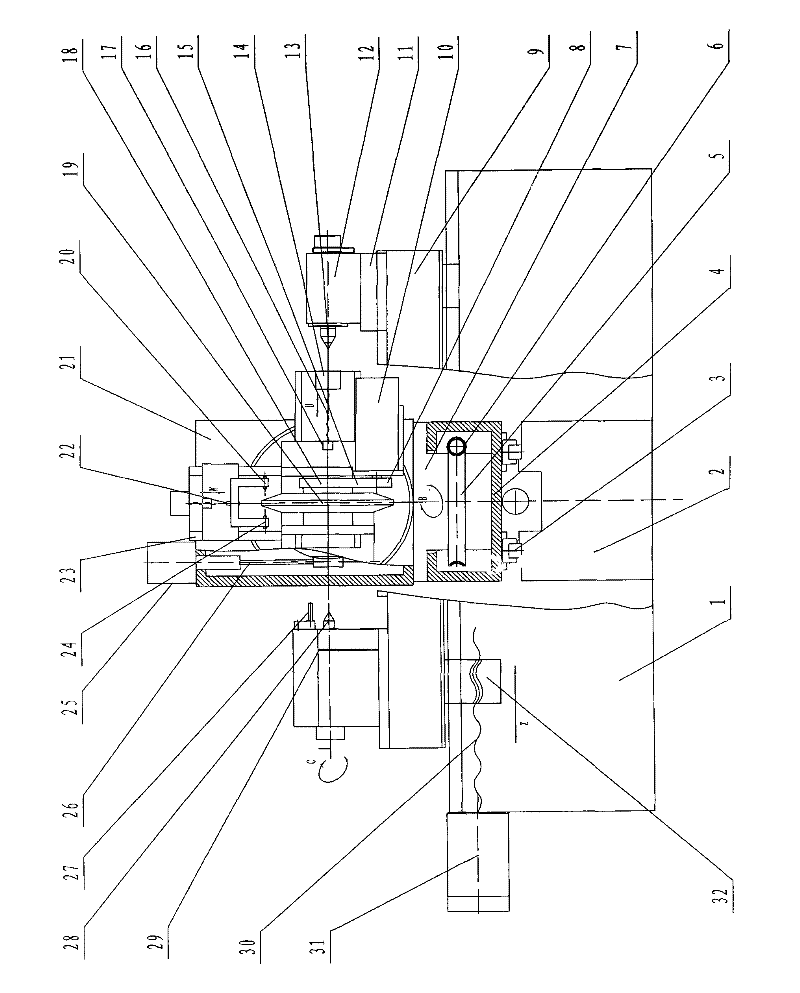

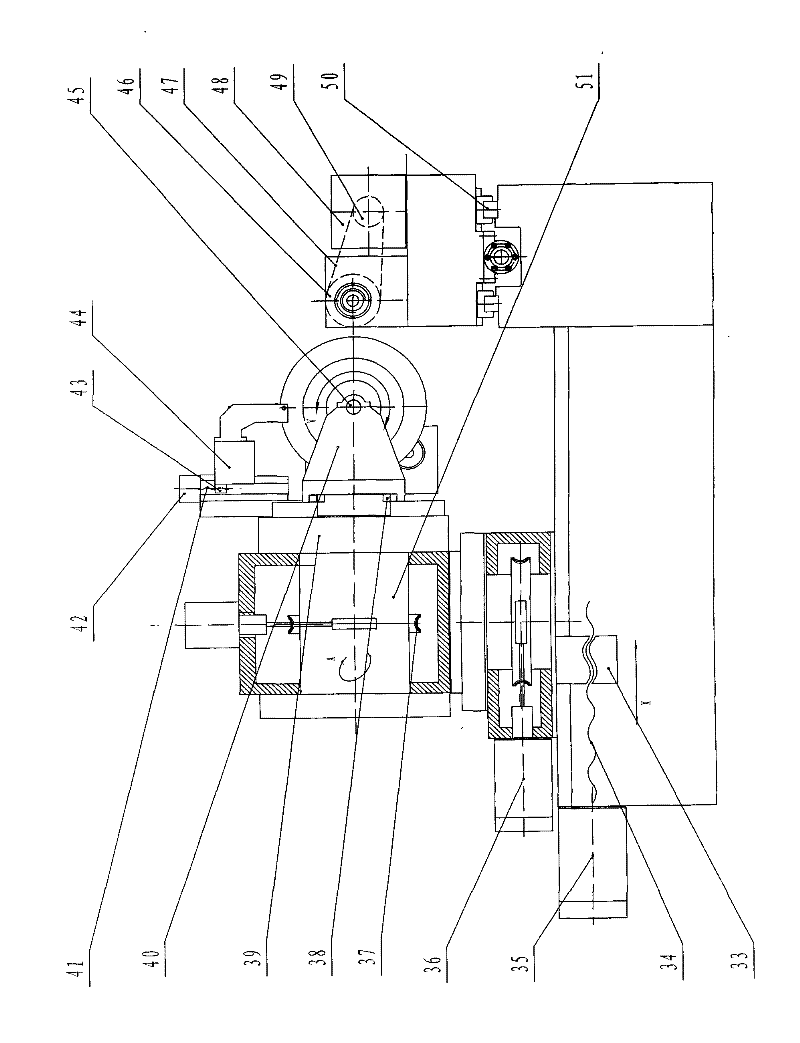

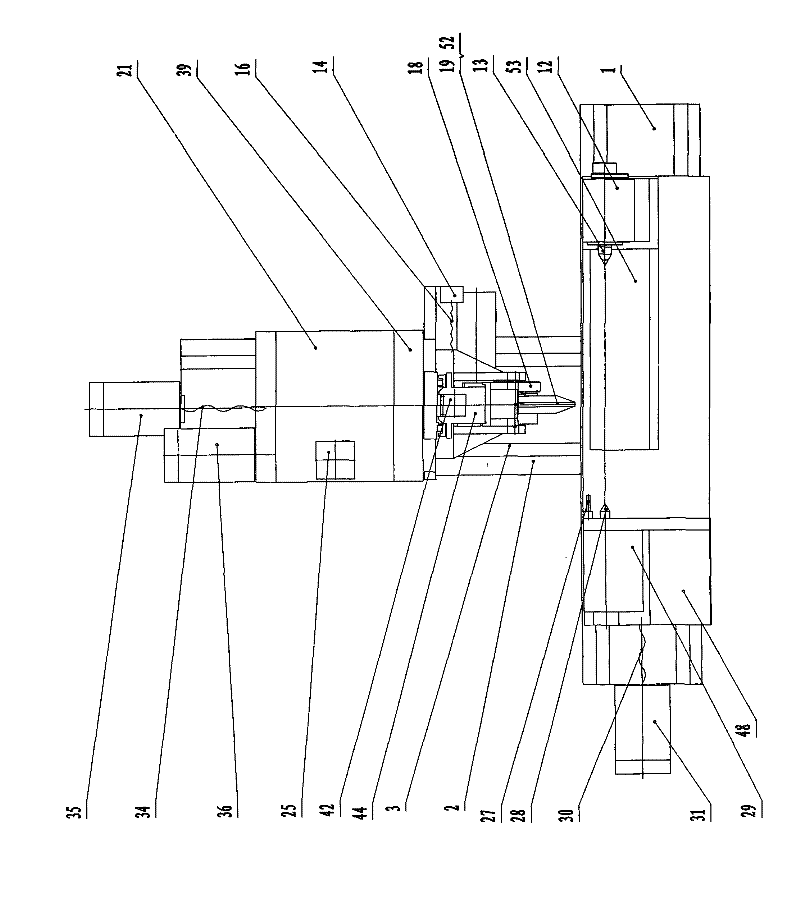

[0025] Attached below figure 1 , 2 , 3 describe an embodiment of the present invention.

[0026] A numerically controlled universal worm grinding machine, comprising a front bed 1, a rear bed 2, a slide table 9, a headstock 29, a tailstock 12, a knife table 4 and a grinding head 52.

[0027] The front end of the rear bed 2 is fixedly connected to the inside of the middle of the front bed 1 to form a "T" shape layout; the upper end of the front bed 1 is equipped with a Z-axis guide rail 50, and the slide table 9 is located on the Z-axis guide rail 50 , and the nut I32 installed on the lower end surface of the sliding table 9 is connected with the Z-axis ball screw 30, and the Z-axis servo motor 31 connected with the Z-axis ball screw 30 drives the sliding table 9 to move linearly along the Z-axis guide rail 50; The left end of slide table 9 is equipped with headstock 29, and headstock top 28 is equipped with on the right end of headstock 29, and the synchronous toothed pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com