ErF3-containing rare earth composite reversible hydrogen storage material and preparation method thereof

A hydrogen storage material and rare earth composite technology, applied in the direction of hydrogen production, etc., can solve the problems of non-reversibility, high decomposition temperature, and no reversibility, so as to improve kinetic performance, reduce hydrogen release temperature, and low hydrogen release The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) In terms of mass percentage, the preparation purity is 98% NaBH 4 powder (purchased by Aladdin Reagent Company) and ErF with a purity of 99.99% 33 Powder (purchased by Aladdin Reagent Company). Weigh 1.194gNaBH 4 and 2.242gErF 3 powder, then mixed;

[0022] (2) Add the mixed powder to the ball mill tank, and add steel balls with a mass ratio of balls to material of 30:1 and a mass ratio of large and small balls of 1:2;

[0023] (3) Ball milling under argon protection, the ball milling speed is set to 400r / min, 25 cycles of ball milling, each cycle rotates for 48 minutes and stops for 12 minutes;

[0024] (4) After the ball milling is completed, the sample is taken out to obtain 3 Rare earth composite reversible hydrogen storage materials.

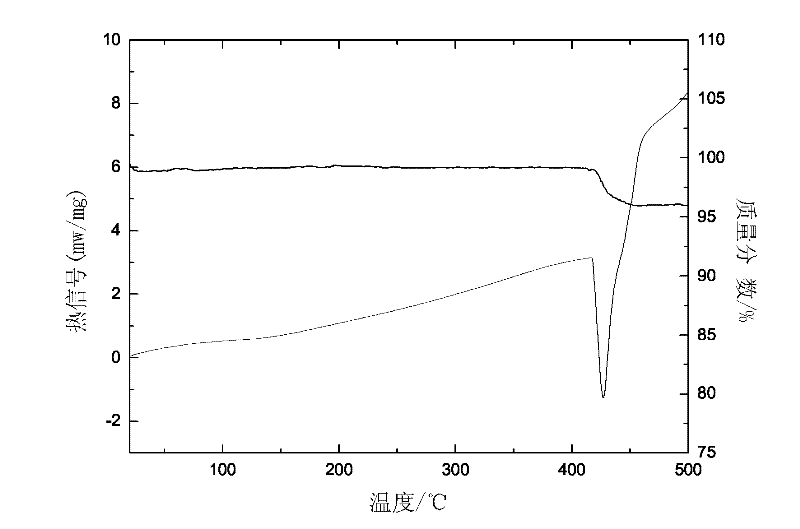

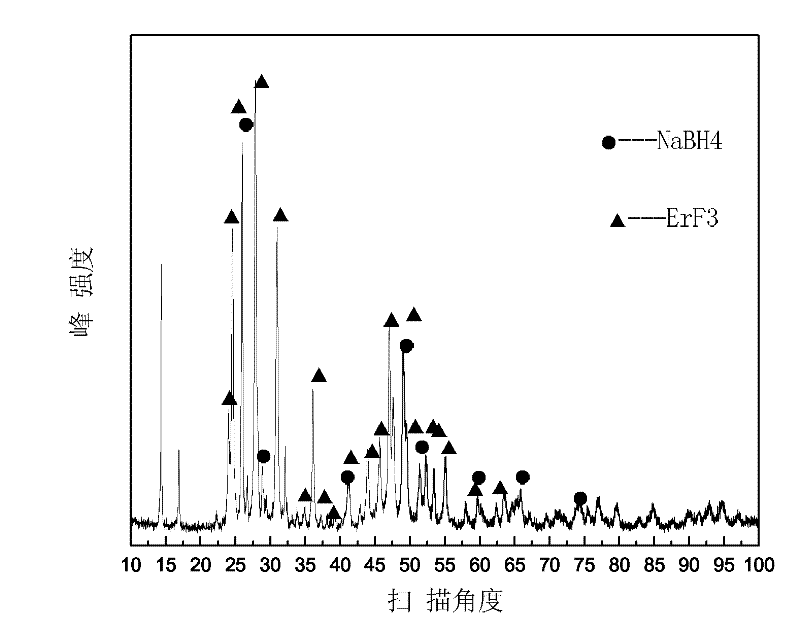

[0025] DSC (Differential Scanning Calorimetry) and XRD (X-ray Diffraction Spectrum) tests were performed on the ball-milled samples.

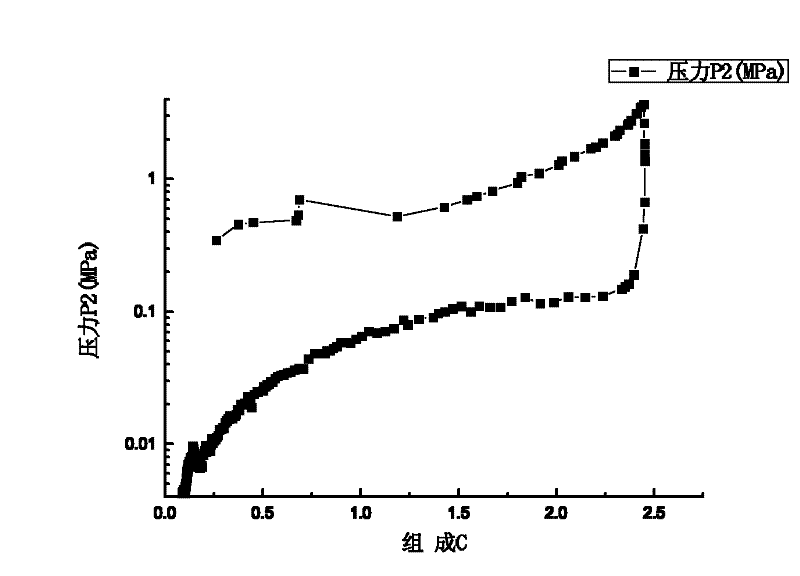

[0026] figure 1 The PCT curve (pressure component temperature curve) of the material a...

Embodiment 2

[0030] (1) In terms of mass percentage, the preparation purity is 98% NaBH 4 powder (purchased by Aladdin Reagent Company) and ErF with a purity of 99.99% 3 Powder (purchased by Aladdin Reagent Company). Weigh 1.194.gNaBH 4 and 2.242gErE 3 powder, then mixed;

[0031] (2) Add the mixed powder to the ball mill tank, and add steel balls with a mass ratio of balls to material of 30:1 and a mass ratio of large and small balls of 1:2;

[0032] (3) Ball milling under the protection of argon, the ball milling speed is set to 400r / min, 50 cycles of ball milling, each cycle rotates for 48 minutes and stops for 12 minutes;

[0033] (4) After the ball milling is completed, the sample is taken out to obtain 3 Rare earth composite reversible hydrogen storage materials.

[0034] DSC and XRD tests were performed on the milled samples.

[0035] DSC results showed that the amount of hydrogen released was 2.86 (wt)%, and the hydrogen released temperature was 420°C.

Embodiment 3

[0037] (1) In terms of mass percentage, the preparation purity is 98% NaBH 4 powder (purchased by Aladdin Reagent Company) and ErF with a purity of 99.99% 33 Powder (purchased by Aladdin Reagent Company). Weigh 1.542gNaBH 4 and 2.242gErF 3 powder, then mixed;

[0038] (2) Add the mixed powder to the ball mill tank, and add steel balls with a mass ratio of balls to material of 30:1 and a mass ratio of large and small balls of 1:2;

[0039] (3) Ball milling under argon protection, the ball milling speed is set to 400r / min, 12 cycles of ball milling, each cycle rotates for 48 minutes and stops for 12 minutes;

[0040] (4) After the ball milling is completed, the sample is taken out to obtain 3 Rare earth composite reversible hydrogen storage materials.

[0041] DSC and XRD tests were performed on the milled samples.

[0042] DSC results showed that the amount of hydrogen released was 3.14 (wt)%, and the hydrogen released temperature was 422°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com