Automatized and integrated MBR (membrane bioreactor) automatic treatment system for ship sewage

An automatic treatment and sewage technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. To achieve the effect of long replacement cycle, high volume load and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A ship equipment company processes 2.4 tons of simulated ship sewage per day, which is equivalent to the daily sewage generated by a cargo ship with 20 crew members. The water volume is representative. The influent water quality indicators are shown in Table 1. It can be seen from Table 1 that the effluent treated by this device fully meets and exceeds the latest discharge standards stipulated in the IMOMEPC15955 resolution of the International Maritime Organization.

[0033] Table 1 Water quality of 5 kinds of wastewater Unit: mg / L

[0034]

[0035]

[0036] Note: * represents the value after coarse grid filtering, otherwise it cannot be detected;

[0037] ◇Indicates that this concept does not exist.

[0038] △ indicates that the quantity is extremely large and has no detection significance;

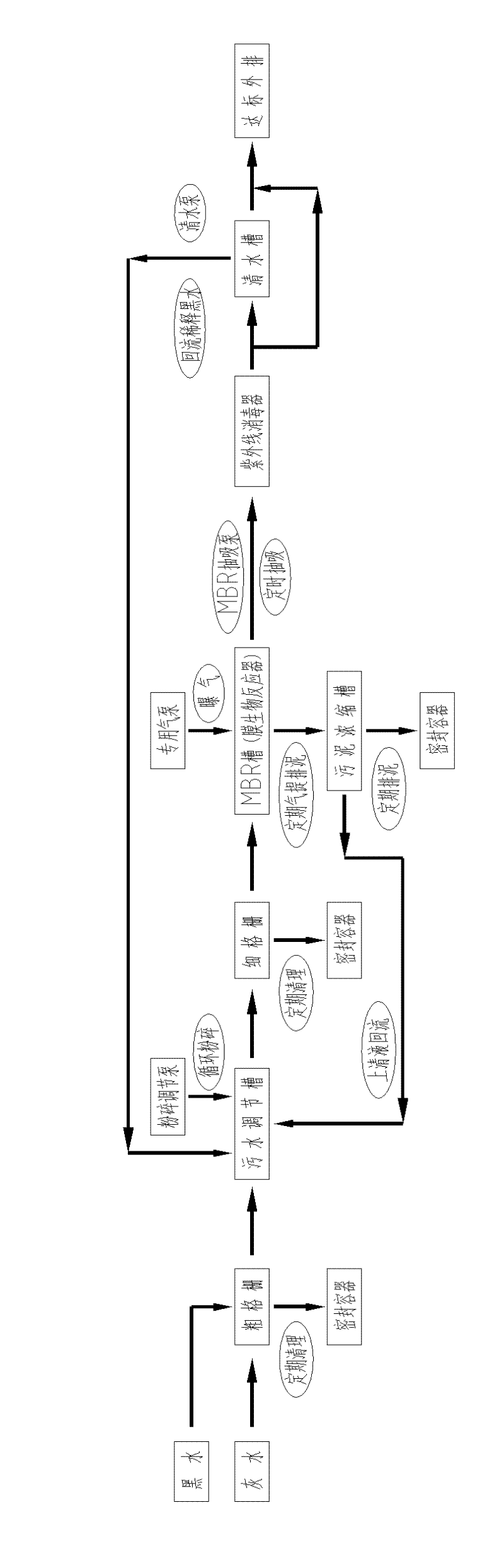

[0039] treatment techniques such as figure 1 The method shown:

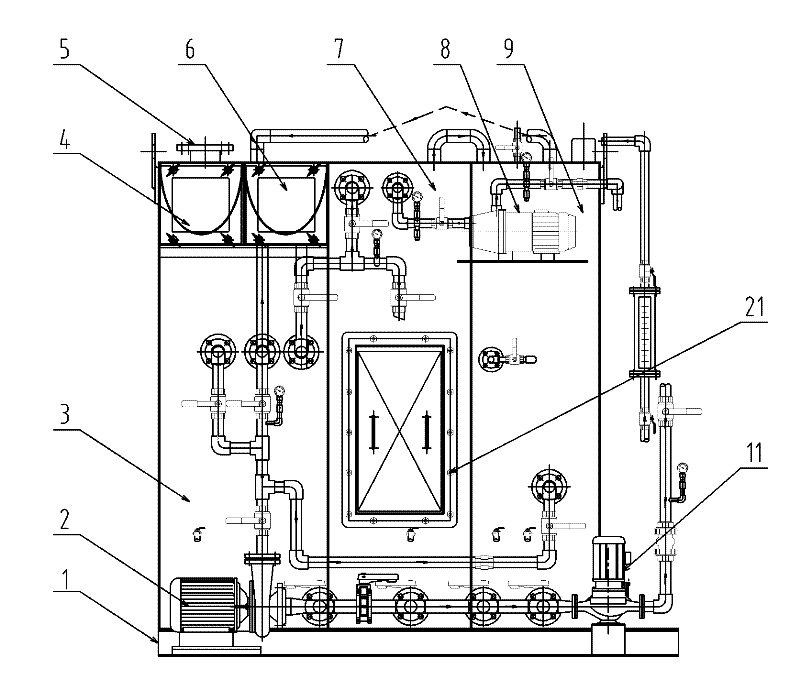

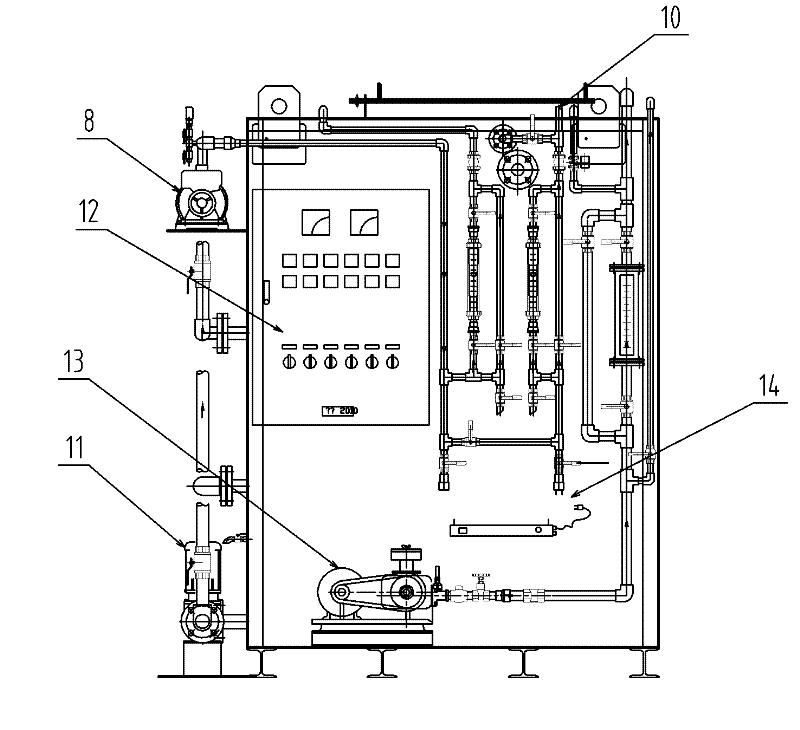

[0040] There are 2 water inlet interfaces in the sewage regulating tank, which mainly receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com