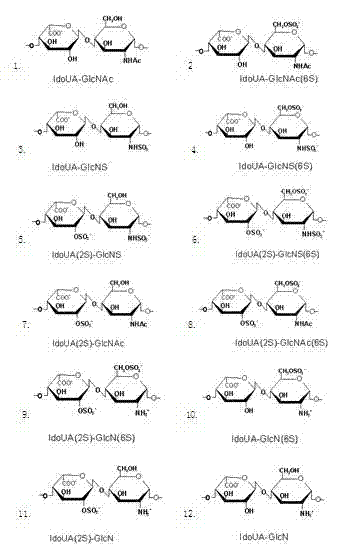

Preparation and purification method for heparitin sulfate disaccharide, and purified product thereof

A technology of heparin sulfate and purification method is applied in the field of preparation and purification of natural products, which can solve the problems of high price, inability to prepare disaccharide structure, and numerous preparation steps, and achieve the effect of simple purification method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] 1. Preparation of pyridinebiose

[0034] ⑴. Calculate the amount of sodium ions (mol) that can be exchanged by 1 gram of H-type cation exchange resin (Amberlite IR-120 H-type) according to the exchange capacity E of the resin in the specification;

[0035] ⑵. Calculate the amount of resin needed to exchange 1 gram of HS disaccharide. The typical disaccharide molecular weight of HS is about 649, and there are 4 sodium ions in one molecule of disaccharide. The calculation method is as follows:

[0036] The amount of sodium ions contained in 1 gram of HS disaccharide (mol) (1g / 649) x4=0.0062mol

[0037] Required resin amount (g): 0.0062 / E=Y grams

[0038] ⑶. Select a glass column with a diameter-to-height ratio of 1:20. Soak Y grams of resin in pure water, rinse repeatedly until neutral, and then pack the column.

[0039] ⑷. Dissolve 100mg of HS disaccharide in 10mL of distilled water, put it together with 300mL of distilled water and the packed resin column at 4°C ov...

Embodiment 1

[0065] The preparation method of described heparin pyridinebiose comprises:

[0066] 1) Pass the heparin disaccharide aqueous solution through the cation exchange resin at 2°C, and then elute with distilled water of 1 times the volume of the resin;

[0067] 2) At room temperature, use pyridine to neutralize the obtained eluent to a pH of 6-6.5 under stirring;

[0068] 3) Freezing the neutralized solution at -70° C. for more than 5 hours, and then freeze-drying in a vacuum freeze dryer to obtain the heparin pyridinediose.

[0069] Described free aminodisaccharide is by following preparation purification method:

[0070] 1) Dissolve heparin pyridinedisaccharide in a mixed solution of 1-methyl-2-pyrrolidone / water, react in a water bath for 8 hours, and the temperature of the water bath is 60°C. The mixture of 1-methyl-2-pyrrolidone and water The volume ratio is: 8:2;

[0071] 2) Cool the reacted solution, add NaOH solution, and place it at -4°C overnight;

[0072] 3) Pass the...

Embodiment 2

[0088] The preparation method of described heparin pyridinebiose comprises:

[0089] 1) Pass the heparin disaccharide aqueous solution through the cation exchange resin at 5°C, and then elute with distilled water 3 times the volume of the resin;

[0090] 2) At room temperature, use pyridine to neutralize the obtained eluent to a pH of 6-6.5 under stirring;

[0091] 3) Freezing the neutralized solution at -70° C. for more than 5 hours, and then freeze-drying in a vacuum freeze dryer to obtain the heparin pyridinediose.

[0092] Described free aminodisaccharide is by following preparation purification method:

[0093] 1) Dissolve heparin pyridinedisaccharide in a mixed solution of 1-methyl-2-pyrrolidone / water, react in a water bath for 8-12 hours, and the temperature of the water bath is 60-70°C. The 1-methyl-2- The volume ratio of pyrrolidone to water is: 9:1;

[0094] 2) Cool the reacted solution, add NaOH solution, and place it at -4°C overnight;

[0095] 3) Pass the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com