Multilayer bed reactor and method for synthesizing chlorinated polyvinyl chloride by using low temperature plasmas

A low-temperature plasma, chlorinated polyvinyl chloride technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large circulation, difficult bed temperature control, inability to continuously operate, etc., to achieve continuous Production, improved initiation efficiency, high energy density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

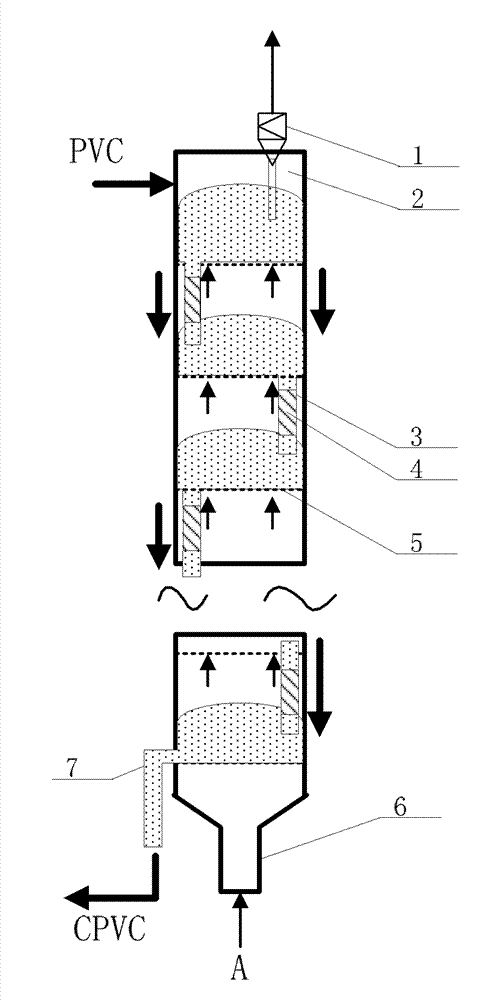

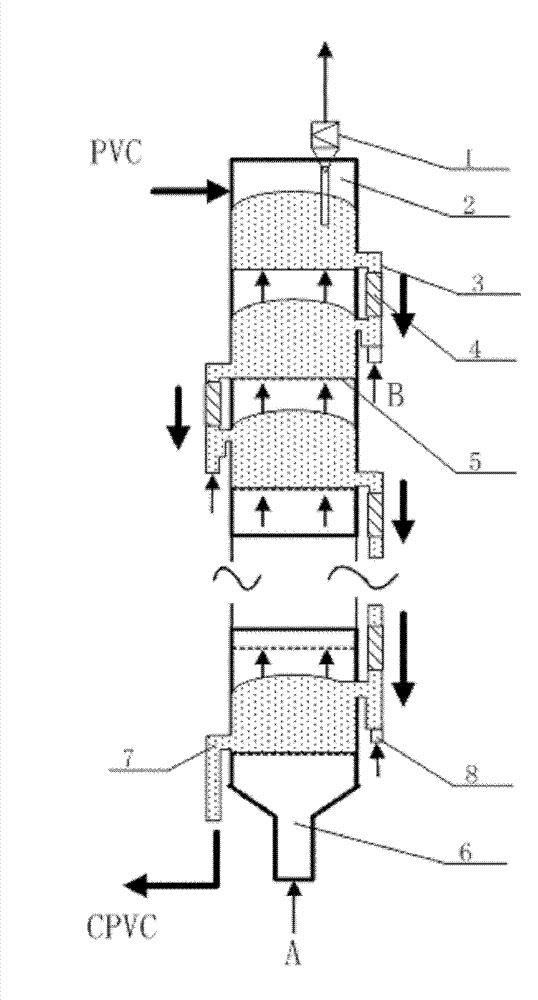

[0039] The fluidized bed reactor has 20 layers, and the layer height is 0.2m. Each layer was operated at atmospheric pressure. The PVC granules with an average particle size of 150 μm are continuously loaded into the fluidized bed reactor at the top of the fluidized bed reactor. In the main body of the fluidized bed reactor, the temperature of the first layer is 60°C, the residence time is 5min, the temperature of the second layer is 100°C, and the temperature between each layer is increased by 2°C, and the temperature of the 20th layer of the fluidized bed reactor is 140°C . On the 2nd to 20th floors, the particle residence time is 5 minutes. The reaction gas is a mixture of chlorine and argon, and the percentage of chlorine is 30%. The particles descend in the inner overflow pipe, pass through the low-temperature plasma area, activate chlorine gas and PVC particles, and undergo chlorination reaction, and the residence time is 2 minutes. The low temperature plasma power d...

Embodiment 2

[0042] The fluidized bed reactor has 15 layers, the layer height is 0.25m, and the operating pressure is 1.5atm. The PVC particles with an average particle size of 150 μm are continuously loaded into the fluidized bed reactor at the upper part of the fluidized bed reactor. In the main body of the fluidized bed reactor, the temperature of the first layer is 60°C, the residence time is 5 minutes, the temperature of the second layer is 80°C, and the temperature between each layer is increased by 3°C, and the temperature of the 15th layer of the fluidized bed reactor is 120°C . On the 2nd to 15th floors, the particle residence time is 10min. The reaction gas is a mixture of chlorine and argon, and the percentage of chlorine is 30%. The particles descend in the inner overflow pipe, pass through the low-temperature plasma area, activate chlorine gas and PVC particles, and undergo chlorination reaction, and the residence time is 1min. The low temperature plasma power density in th...

Embodiment 3

[0045] The fluidized bed reactor has 5 layers, the layer height is 0.8m, and it operates under normal pressure. The PVC particles with an average particle size of 100 μm are continuously loaded into the fluidized bed reactor at the upper part of the fluidized bed reactor. In the main body of the fluidized bed reactor, the temperature of the first layer is 80°C, the residence time is 5 minutes, the temperature of the fifth layer is 125°C, and the temperature of the middle layers is increased by 15°C. On the 2nd to 5th floors, the particle residence time is 60min. The reaction gas is a mixture of chlorine and argon, and the percentage of chlorine is 30%. The particles descend in the outer overflow pipe, pass through the low-temperature plasma area, activate chlorine gas and PVC particles, and undergo chlorination reaction, and the residence time is 1min. The fluidization gas of the outer overflow tube is pure argon, and the power density of the low-temperature plasma is 10W / cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com