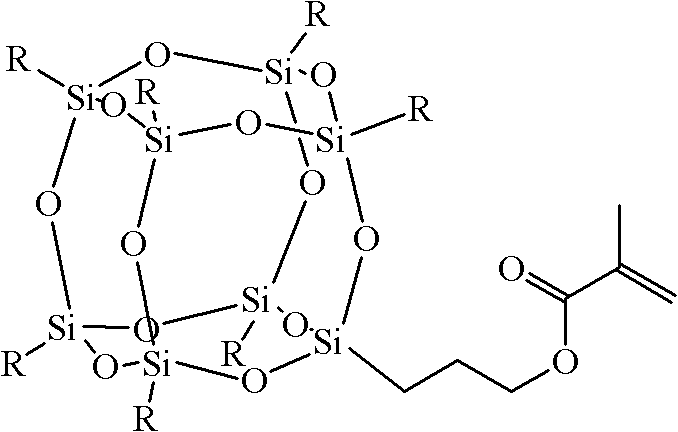

Polyhedral oligomeric silsesquioxane amphiphilic block copolymer and preparation method thereof

A technology of block copolymer and siloxane group, which is applied in the fields of amphiphilic block copolymer and its preparation, amphiphilic macromolecular design and self-assembly morphology research, and achieves the effects of simple preparation, mild reaction conditions and less loss of POSS.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

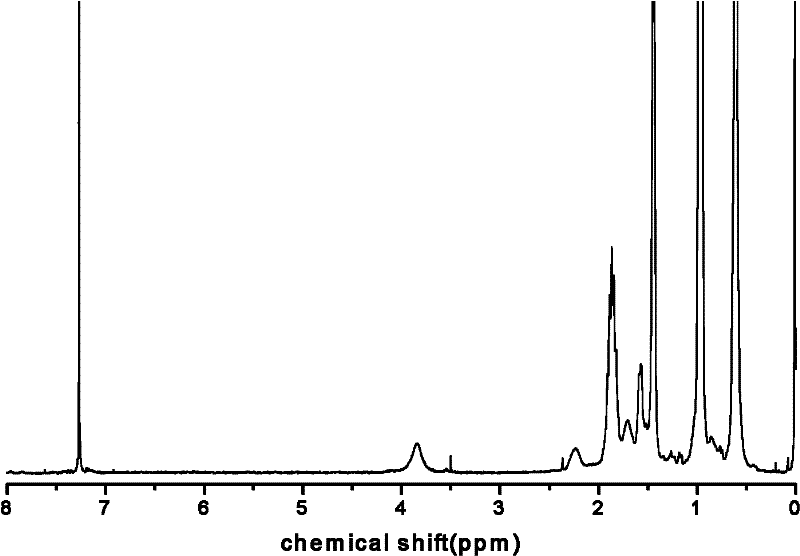

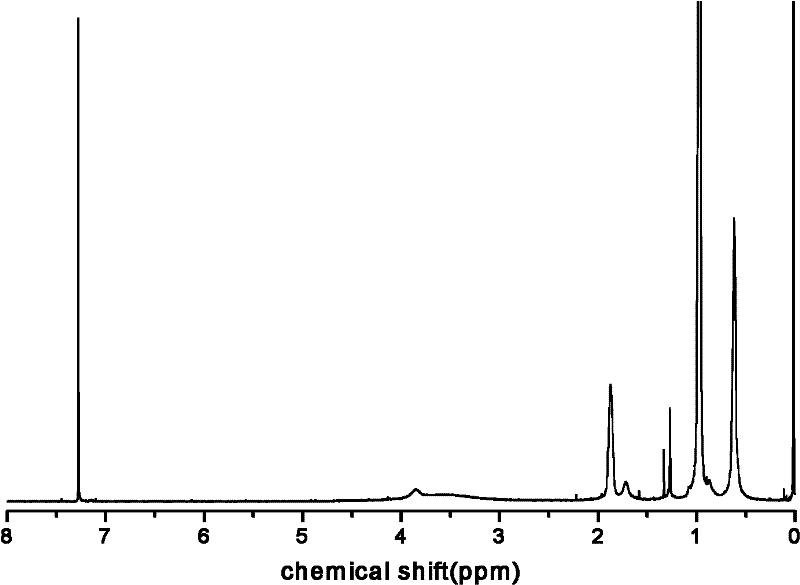

Embodiment 1

[0027]Prepare MAiBuPOSS: CDB: AIBN = 25: 1: 0.33 toluene solution system, the monomer concentration is 0.5 mol / L, put it in a bottle, seal it, freeze and degas it three times, then put it in an oil bath at 65°C for 48 hours, and freeze it to stop the reaction. Take an appropriate amount of the reaction solution and dry it in vacuum. 1 According to HNMR, the conversion rate of the first monomer was 90.2%. According to the molar ratio of tert-butyl acrylate (tBA): polymethacryloxypropyl POSS (MCTA): initiator (AIBN) = 2400: 20: 1, the measured tBA and AIBN are added to the reaction solution, sealed Afterwards, freeze and degas repeatedly for 3 times, 65 ℃ oil bath for 12 hours, freeze to stop the reaction, add a small amount of toluene to dilute and precipitate with methanol, dry, add to excess petroleum ether and stir overnight, filter and dry to obtain polymethacryloxyiso Butyl POSS-tert-butyl acrylate block copolymer, pink solid, its 1 H NMR picture as figure 1 As shown, t...

Embodiment 2

[0029] Similar to Example 1, the difference is that the MAiBuPOSS:CDB:AIBN=15:1:0.33 toluene solution system is prepared in Step 1, and the rest are the same as Example 1. Obtain polymethacryloxypropyl isobutyl POSS-polyacrylic acid amphiphilic block copolymer ABCP2. 1 The conversion rate of the first monomer was determined to be 92.3% by H NMR.

Embodiment 3

[0031] Similar to Example 1, the difference is that the POSS monomer concentration in Step 1 is 0.3mol / mL, and the rest are the same as Example 1. Obtain polymethacryloxypropyl isobutyl POSS-polyacrylic acid amphiphilic block copolymer ABCP3. 1 The conversion rate of the first monomer was determined to be 85.6% by H NMR.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com