Thickness and convexity detection device for plates and strips

A detection device, plate and strip technology, applied in the nuclear technology application field, can solve the problems of instrument dynamic performance decline, swing frequency not too fast, complex mechanical structure, etc., to improve dynamic measurement accuracy, improve dynamic detection performance, and simplify machinery structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

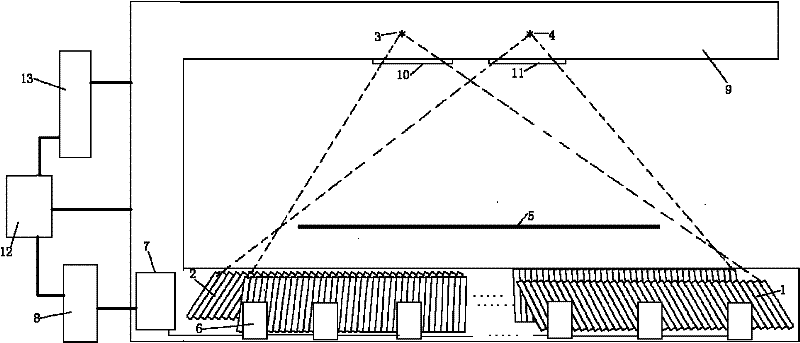

[0017] The specific content of the present invention is described in detail below in conjunction with accompanying drawing:

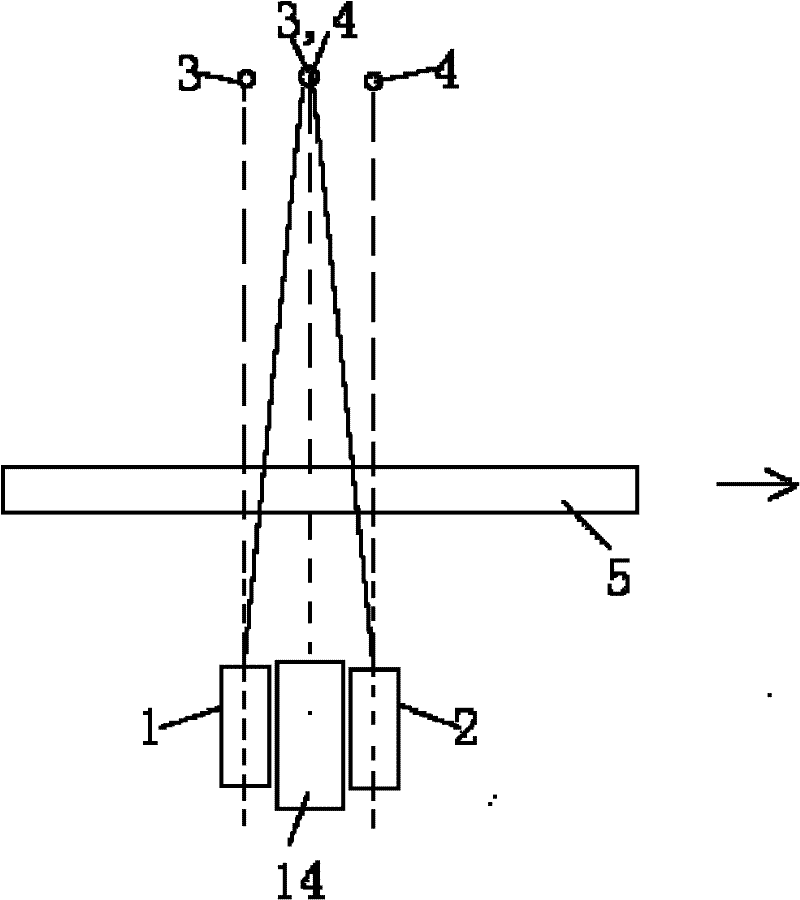

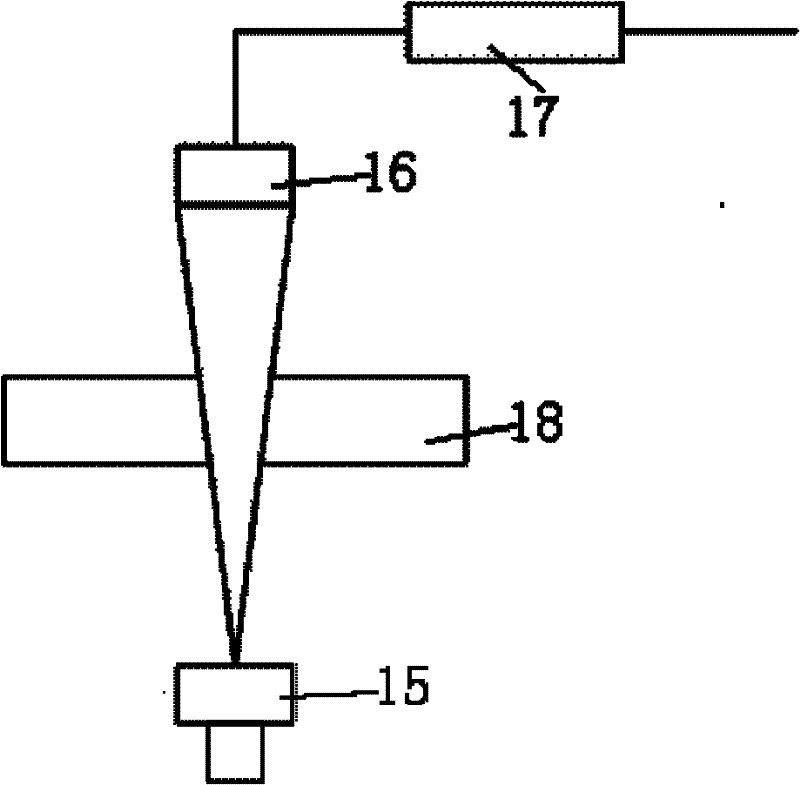

[0018] The present invention proposes a thickness convexity detection device for strips, as in figure 1 As shown, it includes a C-frame 9, two ray sources 3 and 4 installed in the upper arm of the C-frame at intervals along the width direction of the steel plate, installed in the lower arm of the C-frame of the protruding meter and spaced apart along the moving direction of the plate and strip Arranged two rows of high-voltage gas-filled ionization chamber detector arrays 1, 2, and collimators 10, 11 installed under the two radiation sources, the collimator makes the radiation of each radiation source only irradiate the corresponding row of detectors Array, the preamplifier module 6 that links to each other with described detector array, the data acquisition machine 7 that links to each other with above-mentioned preamplifier module, the data processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com