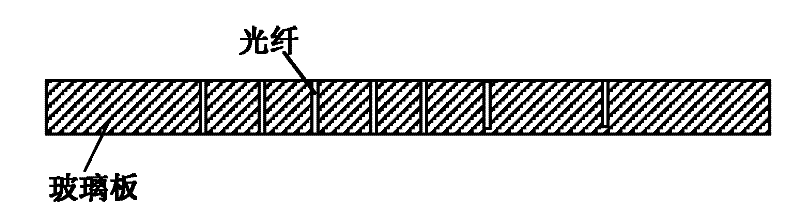

Optical-fibre-embedded glass plate and manufacturing method thereof

A technology of glass plate and optical fiber, which is applied in the coupling of optical waveguide, optical waveguide and light guide, etc., can solve the problems of large optical loss, difficult mode matching, large dielectric constant and dielectric loss, etc., so as to improve frequency and speed, and facilitate Large-scale mass production, good effect of high-frequency electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

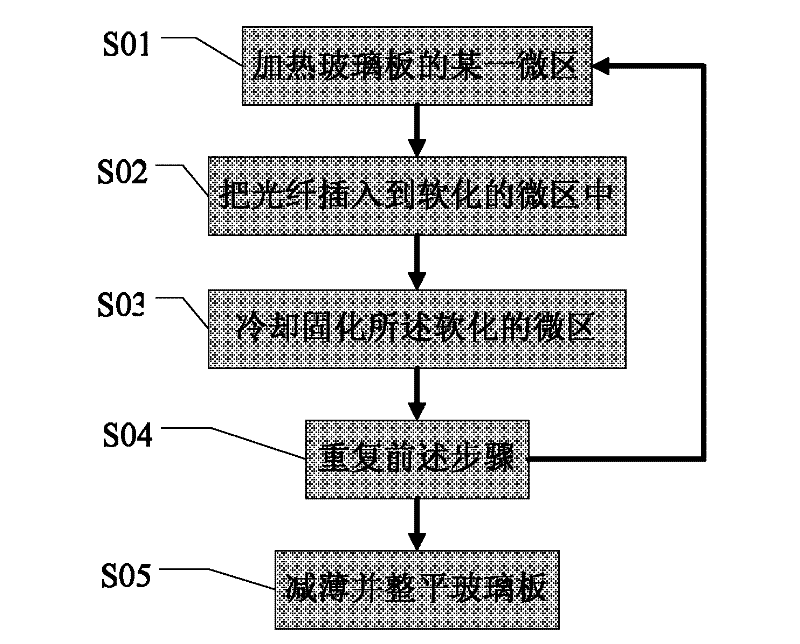

[0072] Figure 4a to Figure 4h The process flow of the manufacturing method of the glass plate structure of Example 1 is shown. in Figure 4h It is a structural schematic diagram of the glass plate of Example 1.

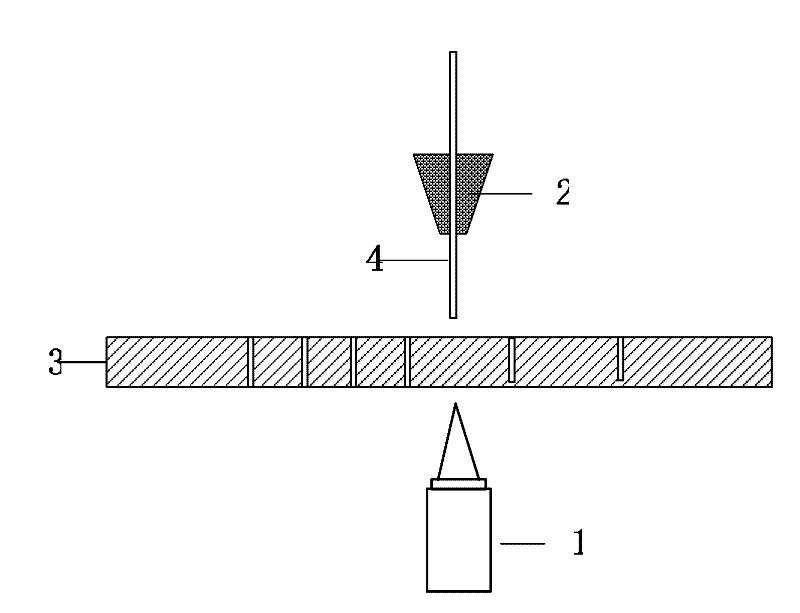

[0073] The manufacturing method of the glass plate structure of the embodiment of the present invention 1 comprises the following steps:

[0074] Step S101, such as Figure 4a As shown, choose Corning Pyrex 7740 glass plate 101, the size is 4 inches disc, the thickness is 400-500 microns, choose silica fiber as embedded fiber material 301, choose laser as micro-zone heating device 203, one has the function of holding and conveying A mechanical device capable of three-axis movement is used as an optical fiber insertion device 201 .

[0075] Step S102 , aligning the laser 203 and the optical fiber insertion device 201 at a certain micro-area position 202 of the glass substrate 101 through an optical system.

[0076] Step S103, such as Figure 4b As shown, the las...

Embodiment 2

[0085] Figure 5 A schematic diagram of the glass plate structure of Example 2 is shown.

[0086] The manufacturing method of the glass plate of Example 2 is mostly similar to that of Example 1, the difference is that after the glass plate is fabricated, different connection mechanisms for connecting with external devices or optical fibers are fabricated, so the same steps are briefly described.

[0087] The manufacturing method of the glass plate structure of the embodiment of the present invention 2 comprises the following steps:

[0088] Step S201, select a glass plate with metal-filled through-glass vias, such as SCHOTT HermeS TM Glass base board. The size is a 4-inch disc, and the thickness is 400-500 microns. The quartz optical fiber is selected as the embedded fiber material 301, the laser is selected as the micro-area heating device 203, and a mechanical device with holding and transporting functions that can move in three axes is used as the metal wire. Insert device...

Embodiment 3

[0093] Figure 6a to Figure 6c The process flow of the manufacturing method of the glass plate structure of Example 3 is shown. in Figure 6c It is a structural schematic diagram of the glass plate of Example 3.

[0094] The manufacturing method of the glass plate structure of the embodiment of the present invention 3 comprises the following steps:

[0095] Step S301, such as Figure 4a As shown, choose Corning Pyrex 7740 glass plate 101, the size is 4 inches disc, the thickness is 400-500 microns, choose silica fiber as embedded fiber material 301, choose laser as micro-zone heating device 203, one has the function of holding and conveying A mechanical device capable of three-axis movement is used as the wire insertion device 201 .

[0096] Step S302 , through the optical system, align the laser 203 and the fiber insertion device 201 with a micro-region 202 on the glass plate 101 where the fiber needs to be embedded and where both ends of the fiber need to be exposed.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com