Radioactive liquid waste treatment device

A radioactive waste and treatment device technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of increasing treatment input and pressure, increasing the difficulty of tail gas treatment, secondary or multiple pollution, etc., to ensure standard discharge and completely remove residual waste Effects of radioactive substances, improving the safety of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

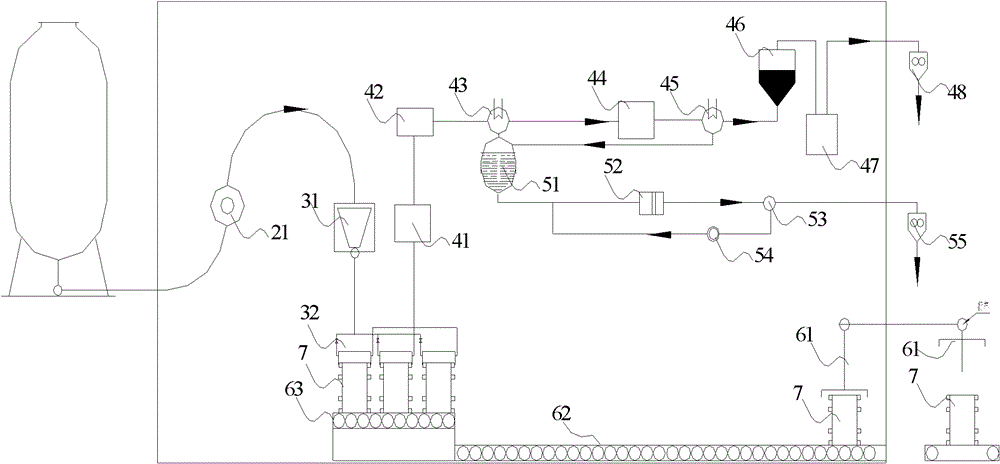

[0015] see figure 1 , the present invention provides a radioactive waste treatment device, including a feeding device for supplying liquid radioactive waste, a volume reduction device for radioactive waste, tail gas and residual liquid formed after the radioactive waste is processed by the volume reduction device, and The raffinate treatment device, the transportation device for the treated radioactive waste after being treated by the volume reduction device; the feeding device, the tail gas and raffinate processing device and the transportation device are respectively connected to the volume reduction device through pipelines; the feeding device , tail gas and residual liquid treatment device, transportation device and volume reduction device are in a vacuum environment as a whole.

[0016] The radioactive waste volume reduction device includes a drying volume reduction device for efficiently removing moisture in radioactive waste. The volume reduction unit is mainly composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com