Triazophos emulsion in water without organic solvent and preparation method thereof

A technology of organic solvent and triazophos, which is applied in the field of water emulsion of broad-spectrum insecticide, acaricide and nematicide triazophos, can solve the problem of large amount of surfactant, easy stratification, and incomplete replacement of organic solvent by water. and other problems, to achieve the effect of obvious environmental protection benefits, reduced usage, and increased water usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

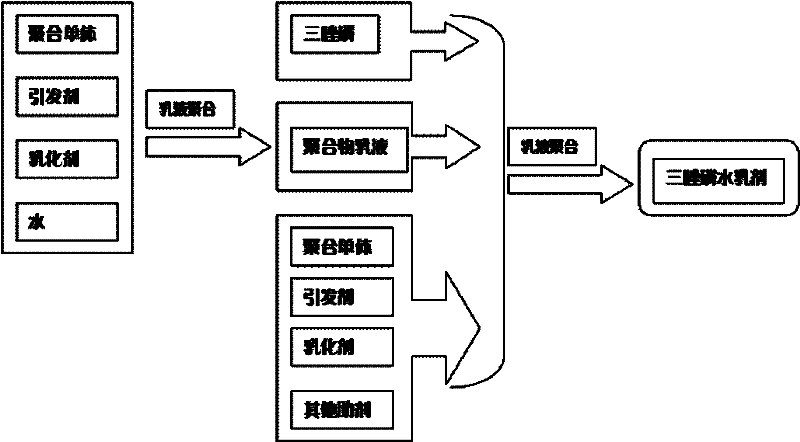

Method used

Image

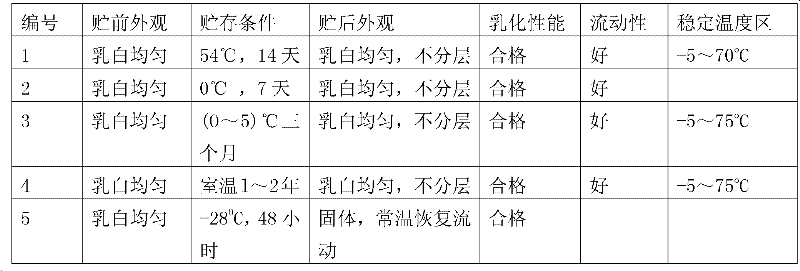

Examples

Embodiment 1

[0025] Add 25g op-10 (emulsifier) in reactor, add 1500mL tap water again, make its reaction dissolve after stirring 5 minutes, add 4.1g potassium persulfate as polymerization initiator, add 180mL methyl acrylate after stirring, in React at 60°C for 3h. Then add 135g of the original drug of triazophos, and at the same time add 10mL of antifreeze agent ethylene glycol, and continue the reaction for 3h. Add 0.5 g of p-benzoquinone after the reaction is completed and cool, and pour it into a container to obtain the required triazophos-water emulsion.

Embodiment 2

[0027] Add 80g of sodium dodecylbenzenesulfonate (emulsifier) to the reaction kettle, then add 1300mL of tap water, stir to make it react and dissolve, add 12.5g of benzoyl peroxide as a polymerization initiator, add 900mL of benzene after stirring evenly Ethylene, reacted at 60°C for 3h. Then add 600g of triazophos as the original drug, and at the same time add 3g of initiator benzoyl peroxide and 150mL of styrene, and react for 4h. After the reaction is completed and cooled, add 2.5 g of stabilizer succinic acid, 2.5 g of polymerization inhibitor p-benzoquinone, and add 30 mL of antifreeze ethylene glycol at the same time, and pour it into a container to obtain the required triazophos-water emulsion.

Embodiment 3

[0029] Add 80g of polyoxyethylene lauryl ether (emulsifier) into the reaction kettle, then add 1300mL of tap water, stir for a period of time to make it react and dissolve, add 12.5g of azobisisobutyronitrile as a polymerization initiator, stir well and then add 900mL of methyl methacrylate was reacted at 60°C for 3h. Then add 600g triazophos former medicine (add initiator azobisisobutyronitrile 3g, methyl methacrylate 150mL simultaneously, react 4h. After reaction finishes cooling, add stabilizer succinic acid 2.5g, polymerization inhibitor p-phenylene Quinone 2.5g, add 30mL of antifreeze agent ethylene glycol simultaneously, pour it into the container and obtain the required triazophos-water emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com