Spiral waveform cutting metal wire as well as manufacturing method and equipment thereof

A production method and metal wire technology are applied to stone processing equipment, manufacturing tools, and other household appliances, etc., which can solve problems such as metal monofilament breakage, gemstone line mark defects, affecting cutting speed and slicing quality, and reduce wear and tear. The effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Figure 6 As shown, the metal wire production equipment of this embodiment includes a pay-off reel 1, a deformation gear 2, a first twist limiting wheel 3, a second twist limiting wheel 4, a flywheel ring 5, a shaft head 6, a bracket 7, a motor 8, a Wire reel 9, traction power part; Wherein: shaft head 6 is fixed on the two ends of flywheel ring 5, and shaft head 6 is fixed on the support 7, and shaft head 6 is driven by motor 8, and take-up reel 9 and pay-off reel 1 are arranged on On the bracket 7, the two ends of the flywheel ring 5 are respectively provided with a first torsion limiting wheel 3 and a second torsion limiting wheel 4, the deformation gear 2 is located between the pay-off reel 1 and the first torsion limiting wheel 3, and the take-up reel 9 is located at After the second torsion limiting wheel 4, a traction power member is provided on the take-up reel 9, and a wire passing wheel 10 is provided between the take-up reel 9 and the second torsion l...

Embodiment 2

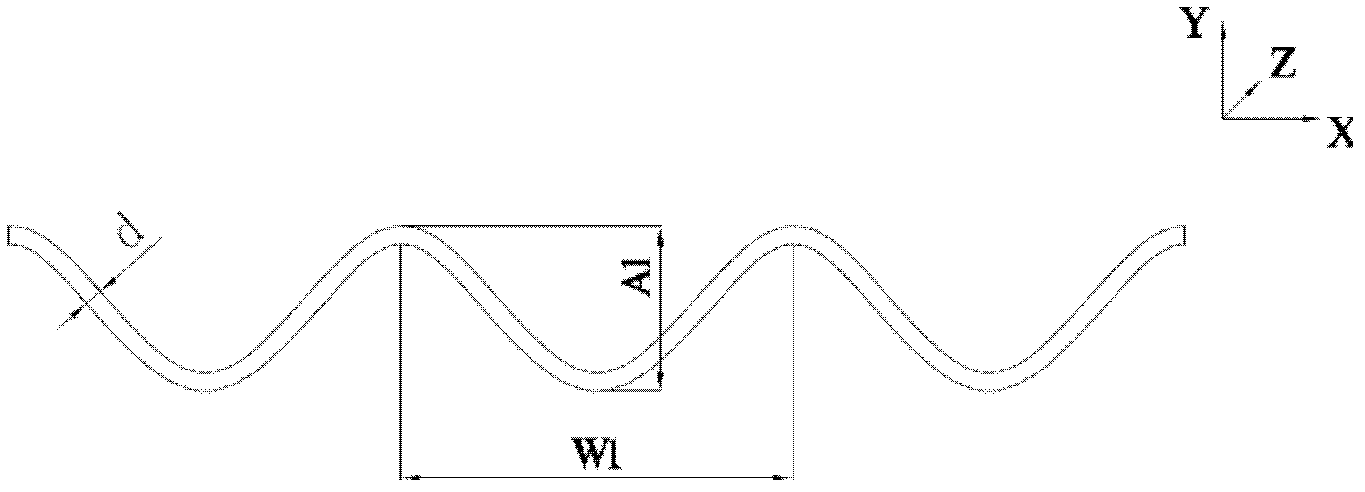

[0034] In this embodiment, the diameter of the metal wire is d=0.05mm, and the periodic waveform formed is wavelength W1=15mm, wave height A1=0.4mm=helix diameter D.

[0035] Such as image 3 Shown is a schematic representation of the y-z plane for two wavelength periods, with a rotation of 90 degrees in each half wavelength period. The produced metal wire is a periodic corrugated metal wire that rotates along the axial center line into a helical shape, and the crests and troughs of the metal wire are distributed symmetrically along the axial center line.

[0036] The angle of wire rotation is determined by how much twist is added to the unit length. The traction speed of the traction power part on the take-up reel 9 is 60m / min in this implementation, and the rotation speed of the flywheel ring 5 is 2000 revolutions / min. 0.033 twists were added to the length of wire to obtain a wire pitch of 30 mm.

[0037] Other implementation conditions are identical with embodiment 1.

Embodiment 3

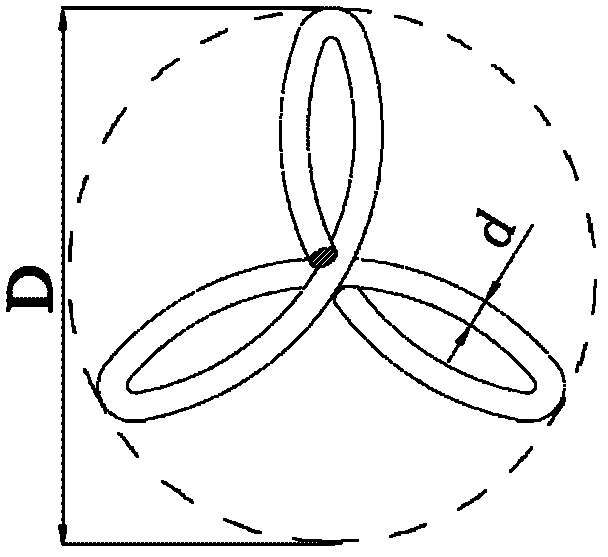

[0039] In this embodiment, the diameter of the metal wire is d=0.5mm, and the periodic waveform formed is wavelength W1=20mm, wave height A1=0.315mm=helix diameter D.

[0040] Such as Figure 4 Shown is a schematic representation of the y-z plane for three wavelength periods, with a rotation of 60 degrees in each half wavelength period. The produced metal wire is a periodic corrugated metal wire that rotates along the axial center line into a helical shape, and the crests and troughs of the metal wire are distributed symmetrically along the axial center line.

[0041] The angle of wire rotation is determined by how much twist is added on the unit length. The traction speed of the traction power part on the take-up reel 9 in this implementation is 60m / min, and the rotation speed of the flywheel ring 5 is 1000 revolutions / min. Adding 0.017 twists to the length of the wire yields a wire pitch of 60 mm.

[0042] Other implementation conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com