Method for extracting betulinic acid from firmiana bark

A technology of sycamore tree and betulinic acid, which is applied in the field of extracting betulinic acid, can solve the problems of difficult products, complex components, and only 2-3% yield, and achieve the effect of low cost, high efficiency, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

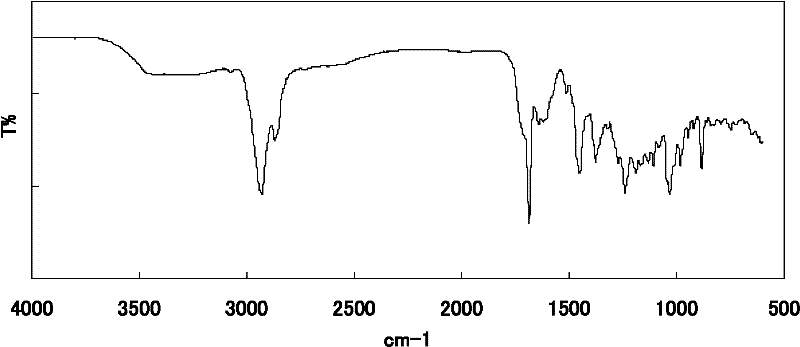

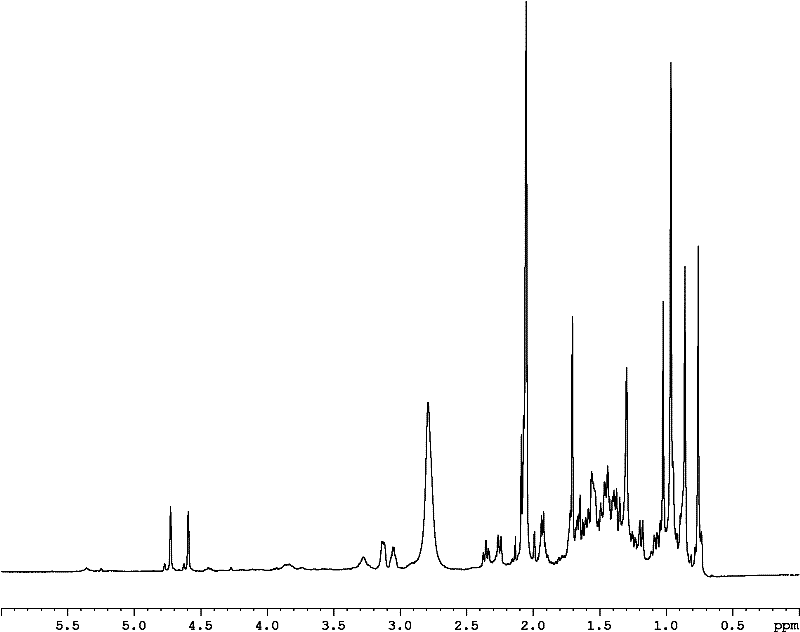

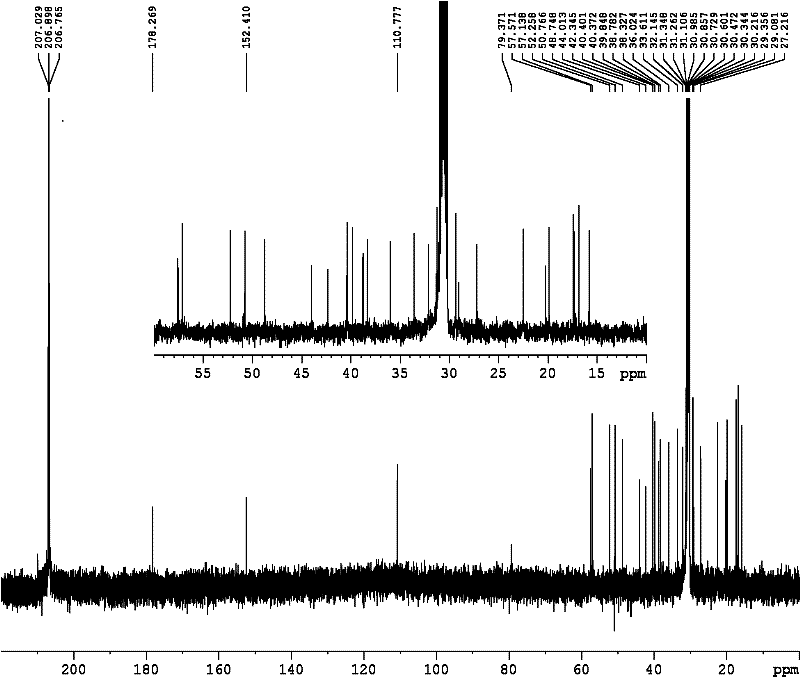

[0025] Get 500g of sycamore bark, add 1000mL of clear water, heat and boil for half an hour, filter with suction, add an equal volume of water after removing the filtrate, boil again for 1 hour, and remove the filtrate again. Subsequently, add 600mL of methanol to the boiled bark, soak at room temperature for 24 hours, and concentrate the filtrate obtained by suction filtration at 30°C under reduced pressure, remove the methanol solvent, and obtain betulinic acid crystal powder, which is dried in the presence of phosphorus pentoxide Dry under reduced pressure at room temperature for 24 hours to obtain 28.5 grams of betulinic acid refined product, with a yield of 5.70%, a purity of 95.8%, and a melting point of 315.8°C. The infrared spectrum, hydrogen nuclear magnetic resonance spectrum, carbon nuclear magnetic resonance spectrum, and mass spectrum of the betulinic acid product See Figure 1~4 .

Embodiment 2

[0027] Get 300g of sycamore bark, add 500mL of clear water, heat and boil for 40 minutes, filter with suction, add 350mL of water after removing the filtrate, boil for the second time for 2 hours, and remove the filtrate again. Subsequently, 400 mL of acetone was added to the boiled bark, soaked at room temperature for 26 hours, the filtrate obtained by suction filtration was concentrated under reduced pressure at 40°C, and the acetone solvent was removed to obtain betulinic acid crystal powder, which was dried in the presence of phosphorus pentoxide Dry under reduced pressure at room temperature for 20 hours. 16.3 grams of refined betulinic acid were obtained, with a yield of 5.43%, a purity of 95.9%, and a melting point of 316.5°C.

Embodiment 3

[0029] Take 600g of sycamore bark, add 800mL of water, heat and boil for one hour, filter with suction, remove the filtrate, add 750mL of ethanol directly to the boiled bark, soak at room temperature for 24 hours, filter with suction, and then use a small amount of ethanol Wash the bark, combine the washings, concentrate the resulting combined solution under reduced pressure at 50°C, and remove the ethanol solvent to obtain betulinic acid crystal powder. After air drying, dry under reduced pressure at room temperature for 30 hours in the presence of phosphorus pentoxide. 32.8 grams of refined betulinic acid were obtained, with a yield of 5.46%, a purity of 95.4%, and a melting point of 317°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap