Method for separating and recovering valuable elements from neodymium-iron-boron wastes

A technology for separation and recovery, valuable elements, applied in the direction of improving process efficiency, can solve problems such as affecting product purity, and achieve the effect of improving purity

Inactive Publication Date: 2011-10-05

林剑

View PDF2 Cites 52 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, during the process of dissolving the rare earth elements in the waste into ions in the hydrochloric acid solvent, some iron elements in the waste are still dissolved into ions, which affects the purity of the product.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

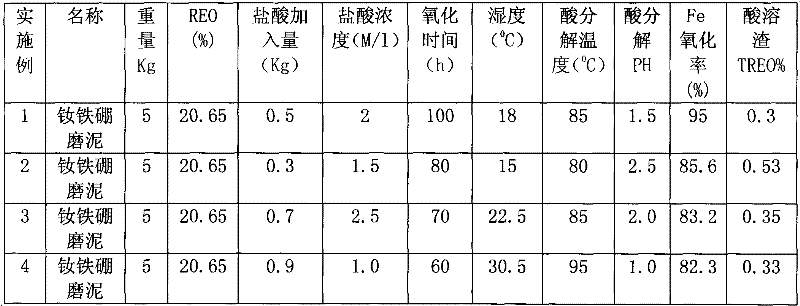

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for separating and recovering valuable elements from neodymium-iron-boron wastes, comprising the following steps of: with the neodymium-iron-boron wastes as raw materials, carrying out air oxidation; finely grinding; carrying out acid decomposition; purifying iron slag; extracting, and separating; precipitating through carbonic acid; washing, and dewatering; burning rare earth; extracting and recovering cobalt and copper; precipitating the cobalt through the carbonic acid, and the like so as to obtain high-purity single rare earth oxide and high-purity cobaltcarbonate. According to the method disclosed by the invention, the preferential leaching of rare earth elements contained in the neodymium-iron-boron wastes is realized and the leaching of iron is inhibited in the acid decomposition process; after hydrochloric acid is added to the neodymium-iron-boron wastes, air oxidation pretreatment is carried out so that a part of metallic iron powder is transformed into iron dichloride which is then oxidized into iron oxide red difficult to dissolve in the hydrochloric acid; and iron elements are mostly separated in the shape of the iron slag in the acid decomposition process, and therefore the purity of products is greatly enhanced.

Description

Technical field [0001] The invention relates to a rare earth metallurgy technology, in particular to a method for separating and recovering valuable elements from NdFeB waste. Background technique [0002] Rare earth resources are strategic resources and non-renewable resources. With the sharp increase in the demand for rare earths in color developers, magnets and electronics industries, it is particularly important to reasonably and effectively improve the utilization of rare earth resources. Using NdFeB waste to recover rare earth elements is one of the important means. Moreover, the use of NdFeB waste to recover rare earth elements has many advantages, such as shortened procedures, reduced costs, and reduced "three wastes" compared with the use of ore to produce rare earth products. At present, the main sources of NdFeB waste are: (1) the furnace pool produced by vacuum smelting, the ultrafine powder produced in the milling process, and the grinding mud produced in the g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B7/00C22B3/10C22B3/22C22B3/38C22B3/46C22B23/00C22B59/00

CPCY02P10/20

Inventor 林剑

Owner 林剑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com