Mask alignment surface shape detection device for DUV (deep ultra violet) photolithographic device

A detection device and mask alignment technology, applied in the field of photolithography, can solve the problems of too many light pulses, reducing the service life of the light source, wasting resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

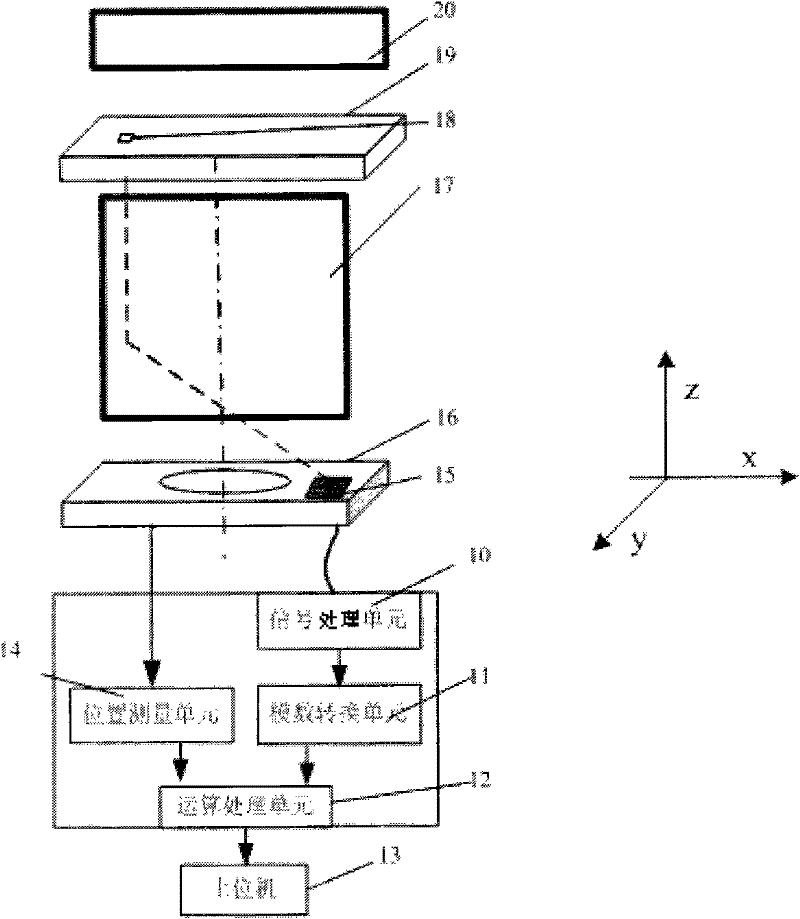

[0043] In the following, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings. For the convenience of describing and highlighting the present invention, relevant components existing in the prior art are omitted from the drawings, and the description of these known components will be omitted.

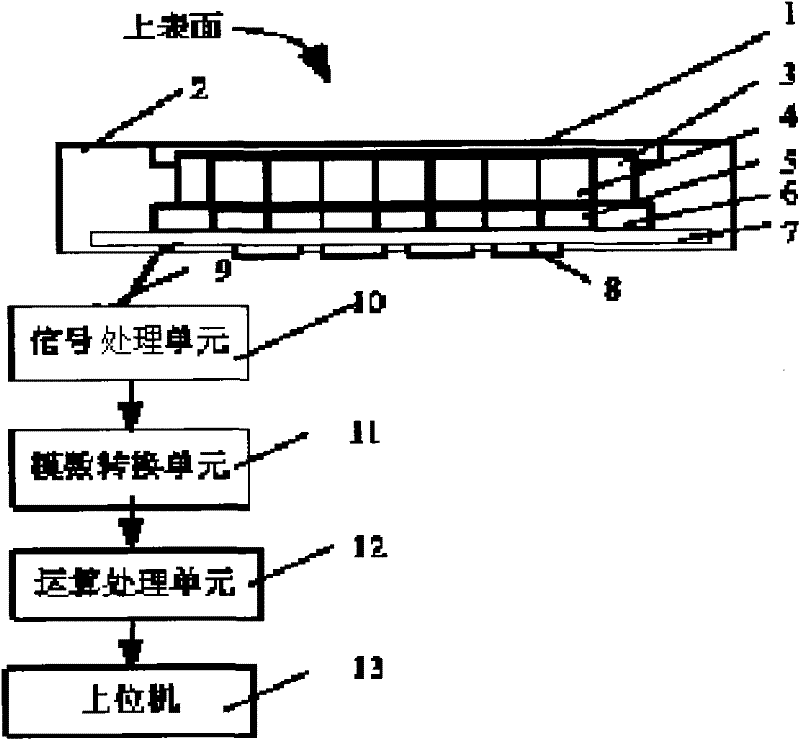

[0044] figure 1 Shown is a schematic structural view of the mask alignment surface shape detection device according to the present invention. As can be seen from the figure, the mask alignment surface detection device of the present invention includes a surface detection mark 1, a reference plate 2, an optical support 3, an optical filter 4, a surface photodiode 5, a spacer 6, a printed circuit Board 7 , amplifier 8 , signal output cable 9 , signal processing unit 10 , analog-to-digital conversion unit 11 , arithmetic processing unit 12 , and host computer 13 .

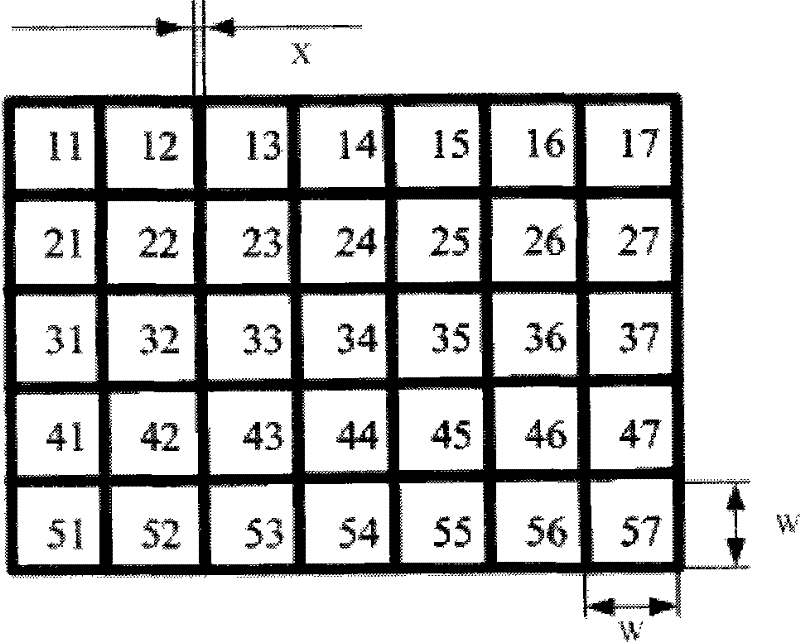

[0045]The surface detection mark 1 includes mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com