Heat radiation type flexible circuit board

A flexible circuit board, heat dissipation technology, used in printed circuit parts, metal pattern materials, electrical connection printed components, etc. The effect of improving performance, prolonging service life and meeting heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

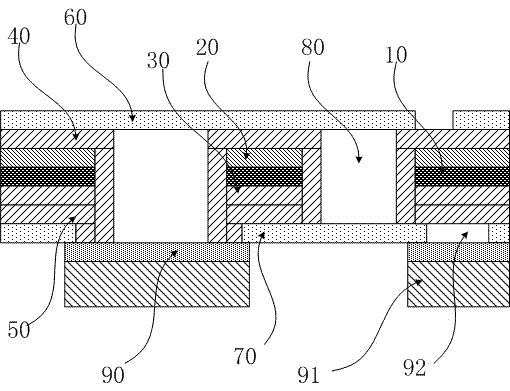

[0009] Embodiment 1: by figure 1 It can be seen from the figure that this heat-dissipating flexible circuit board includes a base layer film 10, the two sides of the base layer film 10 respectively cover the top layer conductive layer 20 and the bottom layer conductive layer 30, and the top layer conductive layer 20 and the bottom layer conductive layer 30 are respectively connected to the ground wires of their respective layers, A top metal layer 40 is plated on the top conductive layer 20, a bottom metal layer 50 is plated on the bottom conductive layer 30, a top cover film 60 is laid on the top metal layer 40, and the bottom conductive layer 30 and then lay the bottom cover film 70, the circuit board also includes a plated through hole 80, the plated through hole 80 is connected to the ground wire of the top conductive layer 20 and the ground wire of the bottom conductive layer 30; this circuit board also includes a high thermal conductivity The adhesive layer 90 and the me...

Embodiment 2

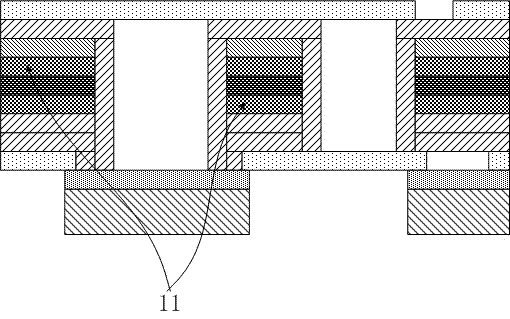

[0013] Embodiment 2: by figure 2 It can be seen from the figure that the two sides of the base layer film 10 are bonded to the top conductive layer 20 and the bottom conductive layer 30 respectively by the adhesive 11, and the adhesive 11 is an acrylic adhesive or a modified epoxy adhesive. The base film 10, the top conductive layer 20, the bottom conductive layer 30 and the adhesive 11 connect the top conductive layer together through the plated through hole 80, and the top metal layer 40 and the bottom metal layer 50 are used as the electroplating layer when the plated through hole is used, and other The structure and principle are the same as those in Embodiment 1, and will not be repeated here.

[0014] This design provides a brand-new structural solution to solve the above problems: change the existing single-sided panel into a double-sided panel, and lay a whole board of copper foil, aluminum foil, silver foil or grid copper foil, aluminum foil, silver foil on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com